21

Lubrication

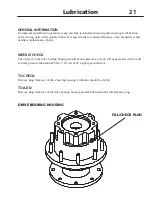

GENERAL INFORMATION

Economical and efficient operation of any machine is dependent upon regular and proper lubrication

of all moving parts with a quality lubricant. Neglect leads to reduced efficiency, wear, breakdown, and

needless replacement of parts.

WEEKLY CHECK

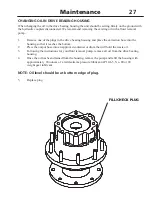

The oil level in the drive bearing housing should be checked once a week. Fill as necessary with a mild

extreme pressure lubricant API-GL-5, No. 80 or 90 weight gear lubricant.

TO CHECK:

Remove plug from rear of drive bearing housing. Lubricant should be visible.

TO ADD:

Remove plug from rear of the drive bearing housing and add lubricant until full. Replace plug.

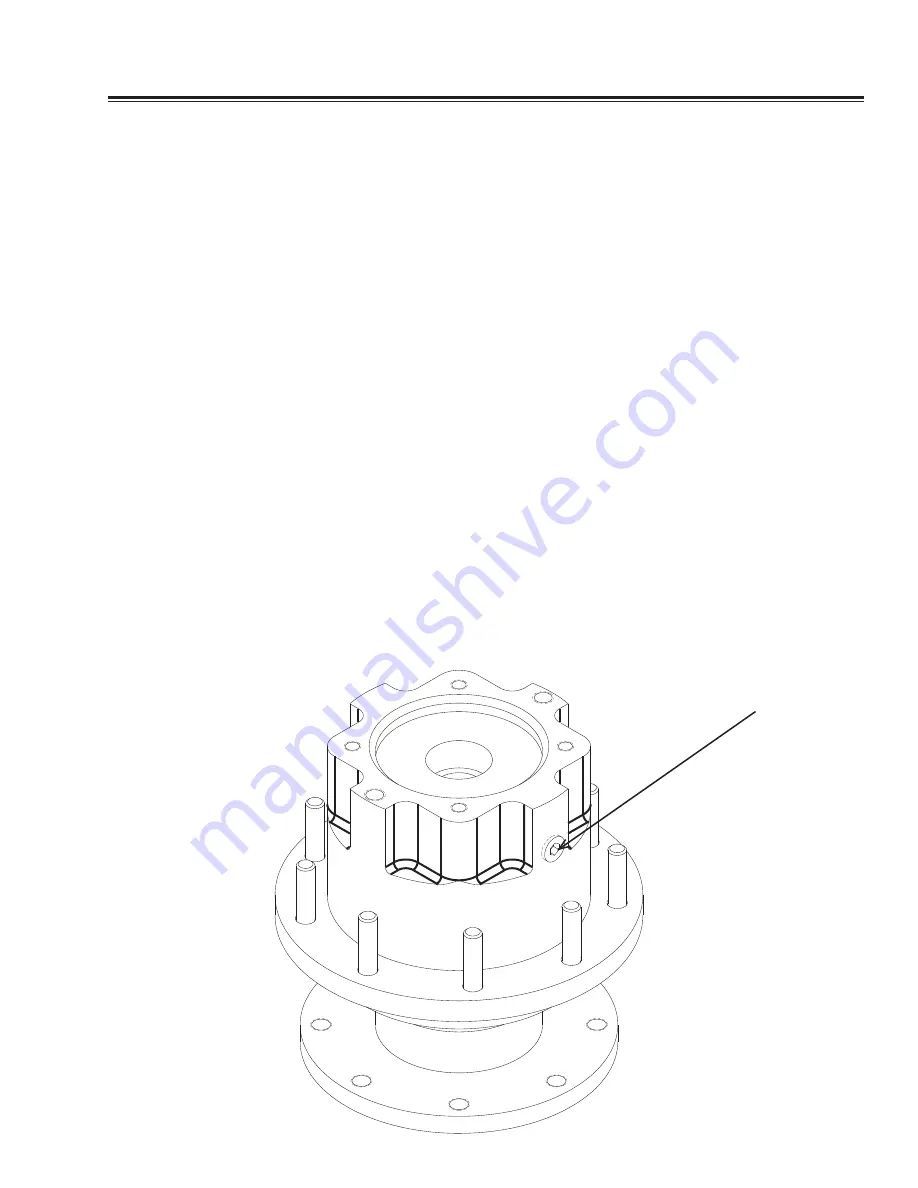

DRIVE BEARING HOUSING

FILL/CHECK PLUG

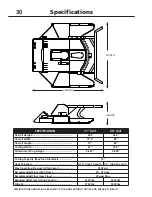

Summary of Contents for PXBC2-8515/20

Page 1: ...MADE IN THE U S A OWNER S MANUAL XBC2 8515 20 XBC2 7715 20 Rev 11 9 2022...

Page 2: ...SPECIFICATIONS AND DESIGN ARE SUBJECT TO CHANGE WITHOUT NOTICE AND WITHOUT LIABILITY...

Page 6: ...SPECIFICATIONS AND DESIGN ARE SUBJECT TO CHANGE WITHOUT NOTICE AND WITHOUT LIABILITY...

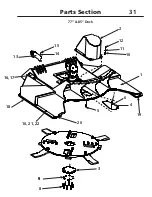

Page 31: ...31 Parts Section 77 85 Deck 8 9 9 13 18 20 10 21 22 16 17 1 19 10 11 14 12 15 2 3 4 6 7 5...

Page 33: ...33 Parts Section 77 x 85 Drive 1 2 12 4 19 20 6 3 7 9 10 18 8 5 11...

Page 35: ...35 77 85 Drive continued Parts Section 30 21 26 31 27 28 33 32 29...

Page 39: ...39 Bolt Kit Blade Kit Mulch Blade Kit 1 2 3 4 5 7 6 77 85 Blades Parts Section...

Page 42: ...42...

Page 43: ...43...

Page 44: ...OWNER S MANUAL OWNER S MANUAL MUST STAY WITH PRODUCT...