18

Installation and maintenance instructions ecoTEC plus 937 0020031552_06

4.8 System

requirements

4.8.1 Water

circulation

system

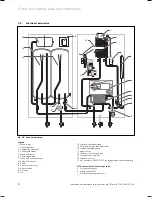

Detailed recommendations concerning the water circu-

lation system can be taken from BS 6798 and BS 5449,

Part 1 (for "Small Bore” and "Micro Bore” central heat-

ing systems). Pipework which does not form part of the

usable heating surface should be insulated to prevent

heat losses and possible freezing up, especially where

the pipes run through roof spaces and ventilated under-

floor spaces. The drain connections must be located in

easily-accessible locations, so that draining the entire

system including the combi boiler and the hot water sys-

tem is possible. The drain connections should be at least

1/2 " (BSP nominal size) and must be in accordance with

BS 2879.

The combi boiler is suitable for Minibore and Microbore

Systems. Copper tubing in accordance with BS 2871

should be used for all water carrying pipework. All capil-

lary joints in all Domestic Hot Water (DHW) pipework

must be made with lead free solder. When a new boiler

is to be fitted to an existing system, it is good practise

that the system is thoroughly flushed before the boiler

if installed in the system. See BS 7593 for full details.

b

Caution!

Risk of equipment and system damage

caused by improper use of cleaning agents.

If you do not use cleaning agents in accord-

ance with the manufacturer's instructions or

if you leave the cleaning agents in the system

for too long, this may lead to deposits and

severe damage to your appliance and system.

Observe the instructions provided by the

manufacturer of the cleaning agent.

Leave cleaning agents in the system for no

longer than 24 hours.

Then flush the system thoroughly.

The cleaning must take place before fitting a new boiler

and in accordance with BS 7593. Recommendations for

use of system cleaning agents can be obtained from

Sentinel, Betz Dearborn Ltd. Widnes, Cheshire, WA8

8UD, Tel. 0151 420 9595, or Fernox, Alpha Fry Technolo-

gies, Tandem House, Marlow Way, Croydon, CR0 4XS,

Tel. 0870 8700362.

>

>

>

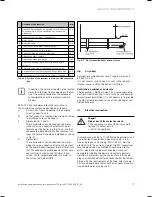

4.8.2 Filling and preparation of the heating system

b

Caution!

The use of unsuitable heating water may

cause aluminium corrosion and therefore

lead to leaks.

In contrast to steel, grey cast iron or copper,

for example, aluminium reacts with alkaline

heating water (pH value > 8.5) to produce

substantial corrosion.

When using aluminium, make sure that the

pH value of the heating water is between

6.5 and a maximum of 8.5.

b

Caution!

Risk of material damage if the heating

water is treated with unsuitable frost or

corrosion protection agents.

Frost and corrosion protection agents may

cause changes in the seals, noises during

heating and may lead to subsequent damage.

Do not use any unsuitable frost or corro-

sion protection agents.

The system can be filled using the incorporated filling

device. This connection must be removed again after

the filling process is complete. If the local Water Author-

ity regulations do not allow temporary connection a

sealed system filler pump with break tank must be used.

The heating system will not be filled automatically from

the domestic hot water side. (Alternative methods of

filling sealed systems are given in BS 5449)

Mixing additives with the heating water can result in

material damage. However, up to now, no incompatibil-

ity with Vaillant appliances has been detected with

proper use of the following products.

When using additives, follow the additive manufactur-

er‘s instructions without exception.

Vaillant accepts no liability for the compatibility of any

additive or its effectiveness in the entire heating sys-

tem.

Additives for cleaning purposes

(subsequent flushing required)

Fernox F3

Jenaqua 200

Jenaqua 300

Jenaqua 400

Sentinel X 300

Sentinel X 400

Additives intended to remain permanently in the sys-

tem

Fernox F1

Fernox F2

Jenaqua 100

>

>

>

–

–

–

–

–

–

–

–

–

4 General requirements

Summary of Contents for ecoTEC plus 937

Page 1: ...For the heating engineer Installation and maintenance instructions GB IE ecoTEC plus 937 VUI...

Page 74: ...74 Installation and maintenance instructions ecoTEC plus 937 0020031552_06...

Page 76: ...76 Installation and maintenance instructions ecoTEC plus 937 0020031552_06...

Page 77: ...Installation and maintenance instructions ecoTEC plus 937 0020031552_06 77...

Page 78: ......

Page 79: ......

Page 80: ...0020031552_06 GBIE 102010 Subject to alterations...