Installation and maintenance instructions ecoTEC plus 937 0020031552_06

27

2

1

3

6

2

4

5

1

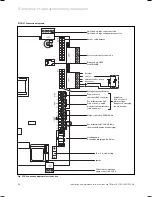

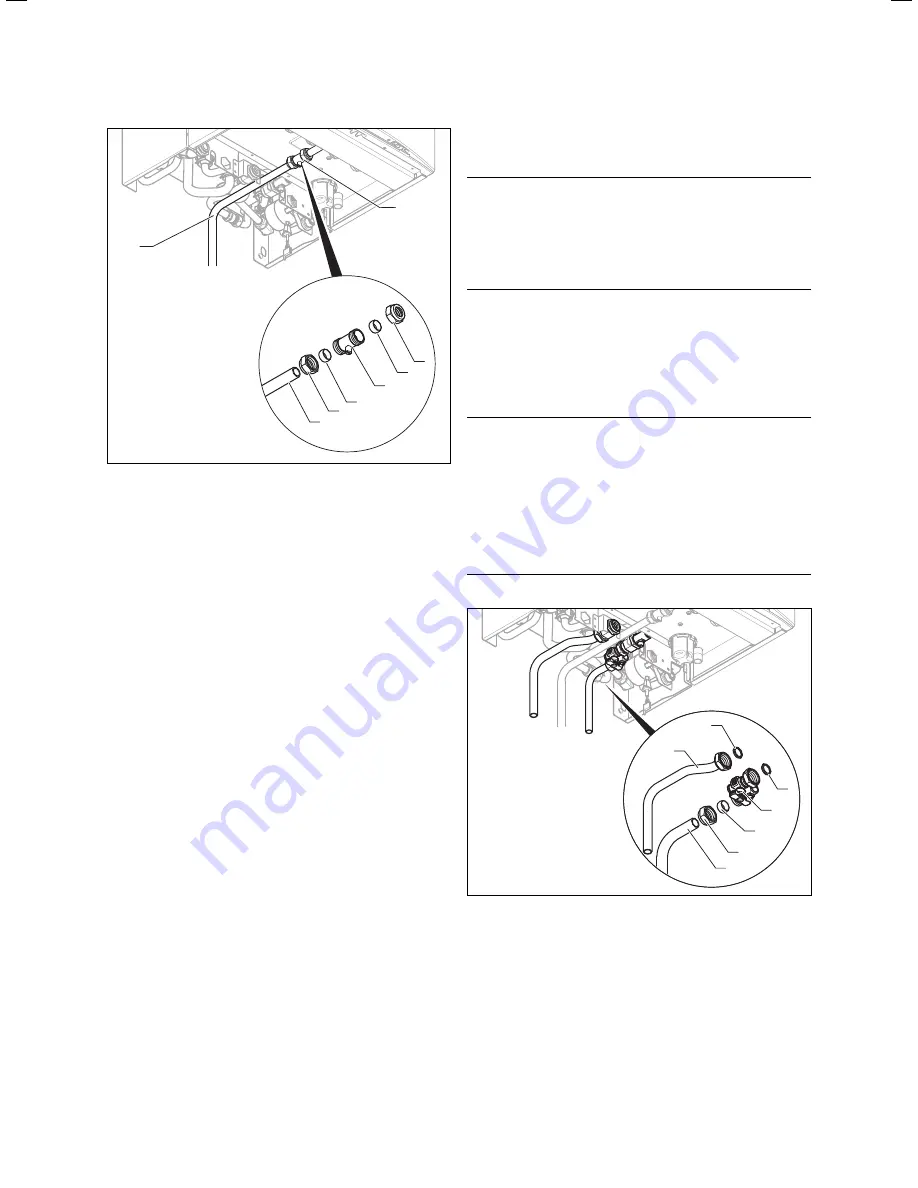

Fig. 5.6 Gas connection

Proceed as follows for gas connection:

Remove the gas connection pipe elbow (

2

) and gas

isolator valve (

1

) from the packaging.

Push the union nut (

3

) and the olive (4) onto the gas

pipe which protrudes from the combi boiler.

Push the gas isolator valve (

1

) onto the gas pipe

which protrudes from the combi boiler up to the stop.

Pull the union nut (

3

) with the olive (

4

) towards the

gas isolator valve. Tighten the union nut hand tight.

Push the union nut (

6

) and the olive (

5

) onto the gas

connection pipe elbow (

2

).

Push the gas connection pipe elbow (

2

) into the gas

isolator valve (

1

) up to the stop.

Pull the union nut (

6

) with the olive (

5

) towards the

gas isolator valve. Tighten the union nut hand tight.

The diameter of the pre-formed copper pipe (

2

) is

22 mm. Connect this pipe to a gas supply pipe having

a diameter of not less than 22 mm.

i

The gas supply pipework must be of sufficient

size so that, at maximum output, a gas pres-

sure of 20 mbar is available at the input to

the combi boiler.

Tighten all connections.

Purge the gas pipe before commissioning.

Check the gas connection for leaks using leak-detect-

ing spray.

>

>

>

>

>

>

>

>

>

>

>

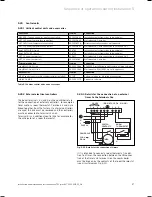

5.12

Connecting the hot and cold water

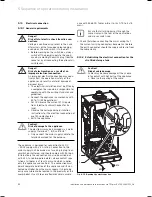

a

Danger!

Risk of scalding and damage due to leaking

water.

Possible leaks in water pipes.

Make sure there is no tension in the supply

lines when they are installed.

b

Caution!

Risk of damage to gas shut-off valves

caused by heat transfer.

If the final connections are soldered, the heat

transferred during the process may damage

the gas shut-off valves.

Use extra care when soldering.

b

Caution!

Risk of damage to the appliance.

Residue in the pipes, such as welding beads,

scale, hemp, putty, rust and coarse dirt, may

be deposited in the appliance and cause mal-

functions.

Flush the cold water inlet pipe thoroughly

before connecting the appliance in order to

remove any residue that may be there.

1

2

3

4

5

6

7

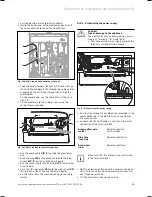

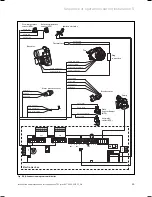

Fig. 5.7 Installing the cold water and hot water connections

Remove the two copper tails (

5

,

6

) for water connec-

tion, the cold water isolating valve (

2

) and the union

nut (

4

), olive (

3

) and fibre seals (

1

,

7

) from the pack-

aging.

Insert the fibre seal (

1

) and screw the cold water iso-

lating valve (

2

) to the cold water connection of the

shift load storage tank.

>

>

>

>

>

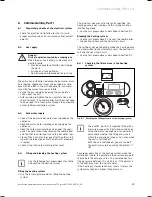

Sequence of operations during installation 5

Summary of Contents for ecoTEC plus 937

Page 1: ...For the heating engineer Installation and maintenance instructions GB IE ecoTEC plus 937 VUI...

Page 74: ...74 Installation and maintenance instructions ecoTEC plus 937 0020031552_06...

Page 76: ...76 Installation and maintenance instructions ecoTEC plus 937 0020031552_06...

Page 77: ...Installation and maintenance instructions ecoTEC plus 937 0020031552_06 77...

Page 78: ......

Page 79: ......

Page 80: ...0020031552_06 GBIE 102010 Subject to alterations...