Installation and maintenance instructions ecoTEC plus 937 0020031552_06

43

6.9.2 Checking the gas flow rate

The boiler is fitted with a multifunctional automatic gas

valve which ensures that the precise air/gas ratio is pro-

vided under all operating conditions. The gas flow rate

has been set during production and does not require

adjustment. With the front casing fitted check the gas

flow rate of the boiler as follows:

Start the boiler by activating the test program P.1 as

described in section 9.2.

In addition, ensure that maximum heat can be dissi-

pated into the heating system by turning up the room

thermostat.

Alternatively, fully open the hot water taps to ensure

full flow rate through the boiler.

Wait at least 5 minutes until the boiler has reached

its operating temperature.

Ensure that all other gas appliances in the property

are turned off.

Measure the gas flow rate at the gas meter.

Check that the gas flow rate is as stated in Table 6.1.

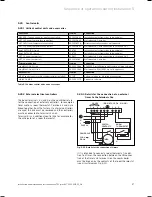

Nominal net

heat input in

kW

as per

BS EN 483

Gas flow rate

Natural gas in m

3

/h

Propane in kg/h

n 5 % - 10 % n 5 % - 10 %

37.8

4.00

4.20

3.60

2.94

3.09

2.65

Table 6.1 Gas flow rate

If the measured gas flow rate lies outside the toler-

ance limits specified in Table 6.1, do not operate the

boiler and inform the Vaillant Service Solutions

(0870 6060 777).

If the measured gas flow rate is within the tolerance lim-

its shown in Table 6.1, then proceed as follows:

Take the boiler out of operation by

Pressing the “

+

” and “

i

” buttons simultaneously

and turn down both thermostat control knobs.

Allow the boiler to cool down by turning off water

taps and allow pump overrun to operate for a mini-

mum of two minutes.

Record the boiler maximum gas flow rate onto the

Benchmark gas boiler commissioning checklist.

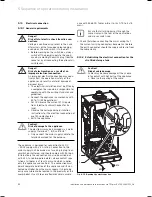

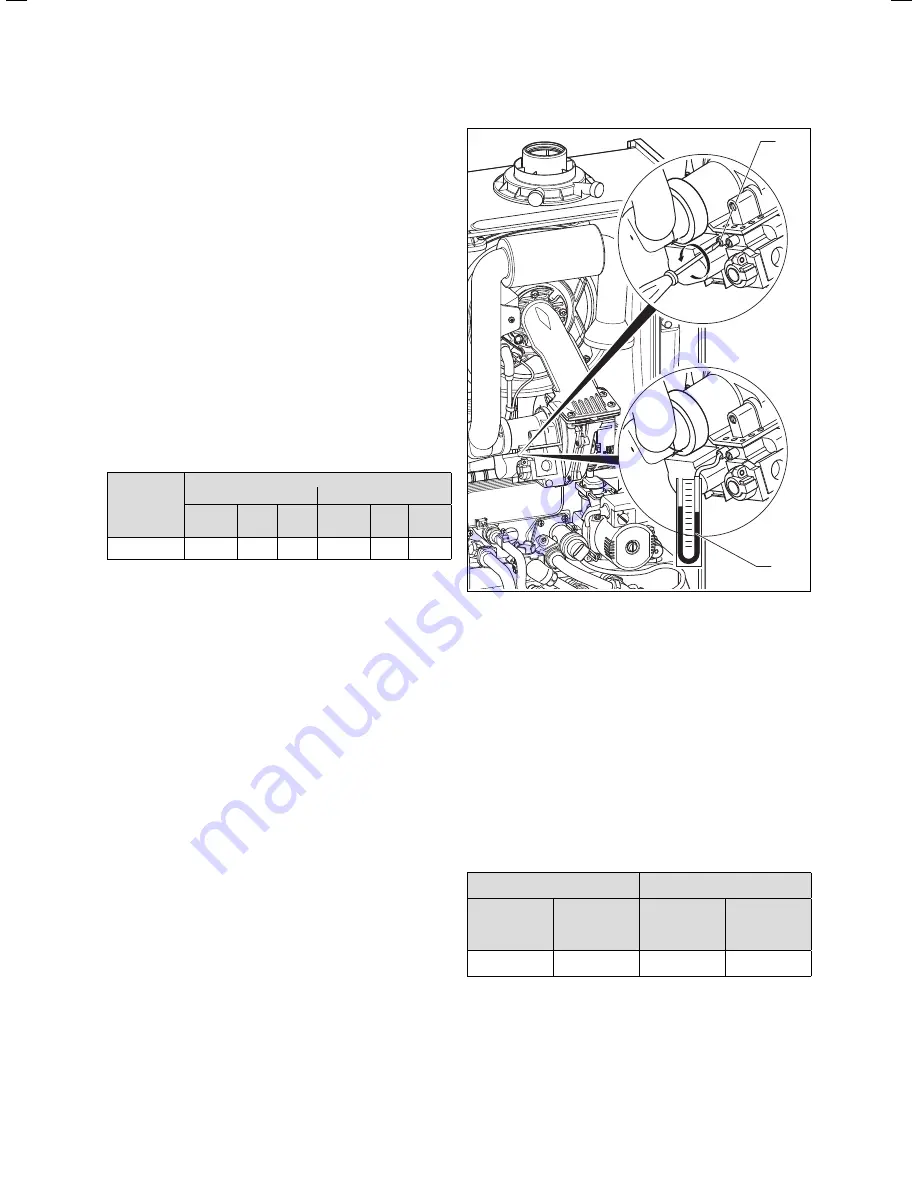

6.9.3 Checking the gas inlet working pressure

Ensure that the gas inlet working pressure can be

obtained with all other gas appliances in the property

working.

Remove the front casing from the boiler.

Close the gas isolation valve of the boiler.

>

>

>

>

>

>

>

>

>

–

–

>

>

>

>

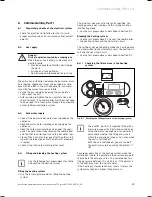

1

2

Fig. 6.7 Measuring the gas inlet working pressure

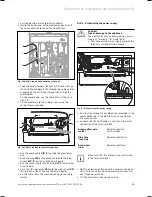

Loosen the sealing screw marked “

in

” (

1

) on the gas

valve.

Connect a digital pressure gauge or U-tube manome-

ter (

2

).

Open the gas isolation valve of the boiler.

Start the boiler by activating the test program “

P.1

”

as described in section 9.2.

In addition, ensure that maximum heat can be dissi-

pated into the heating system by turning up the room

thermostat.

Alternatively, fully open the hot water taps to ensure

full flow rate through the boiler.

With the boiler operating at full load check that the

gas inlet working pressure at the reference test

point (

1

) complies with the requirements of Table 6.2.

Natural gas (G20)

LPG (G31)

Minimum

pressure at

reference test

point in mbar

Maximum

pressure at

reference test

point in mbar

Minimum

pressure at

reference test

point in mbar

Maximum

pressure at

reference test

point in mbar

15

23

23

43

Table 6.2 Gas inlet working pressures at the reference test

point

Should the pressure recorded at the reference test

point in the boiler be lower than indicated (Table 6.2)

>

>

>

>

>

>

>

>

Commissioning, Part I 6

Summary of Contents for ecoTEC plus 937

Page 1: ...For the heating engineer Installation and maintenance instructions GB IE ecoTEC plus 937 VUI...

Page 74: ...74 Installation and maintenance instructions ecoTEC plus 937 0020031552_06...

Page 76: ...76 Installation and maintenance instructions ecoTEC plus 937 0020031552_06...

Page 77: ...Installation and maintenance instructions ecoTEC plus 937 0020031552_06 77...

Page 78: ......

Page 79: ......

Page 80: ...0020031552_06 GBIE 102010 Subject to alterations...