50

Installation and maintenance instructions ecoTEC plus 937 0020031552_06

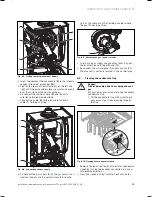

Always perform the following steps

prior

to inspection

or maintenance work:

Switch off the main switch.

Disconnect the boiler from the power mains by

disconnecting the mains plug or

de-energising the boiler via an isolating device with

a contact opening of at least 3 mm (e. g. fuses or

power switches).

Further check for electrical isolation of the appliance

by use of a test meter.

Close the gas isolation valve.

Close the service valves in the heating flow and

return.

Remove the front casing from the boiler.

When removing any water carrying components

ensure that water is kept away from all electrical

components.

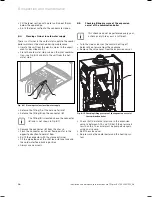

Always perform the following steps after performing

any inspection or maintenance work:

Always use new seals and O-rings when parts are

replaced.

Open the service valves in the heating flow and

return.

Reconnect the boiler to the power mains.

Switch the main switch on.

Fill the heating circuit of the boiler to a pressure of

between 1.0 and 2.0 bar if required.

Bleeding the heating installation (see section 6.4, Fill-

ing and bleeding the heating system).

Open the gas isolation valve.

Check the boiler for gas and water leaks.

If necessary, refill and re-bleed the heating installa-

tion.

Replace the front casing to the boiler.

Carry out a functional check of the boiler

(see section 7).

Always check earth continuity, polarity and resist-

ance to earth with a multimeter after any service

work and after replacing any electrical component.

8.1.3 Checking

the

CO

2

concentration

i

Checking/adjustment of the CO

2

concentra-

tion is required in the following instances:

- replacement of gas valve,

- conversion to or from Natural Gas/LPG

- or if an incorrect combustion is suspected.

>

>

–

–

>

>

>

>

>

>

>

>

>

>

>

>

>

>

>

>

>

4

3

2

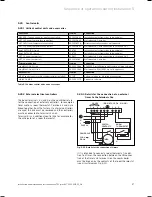

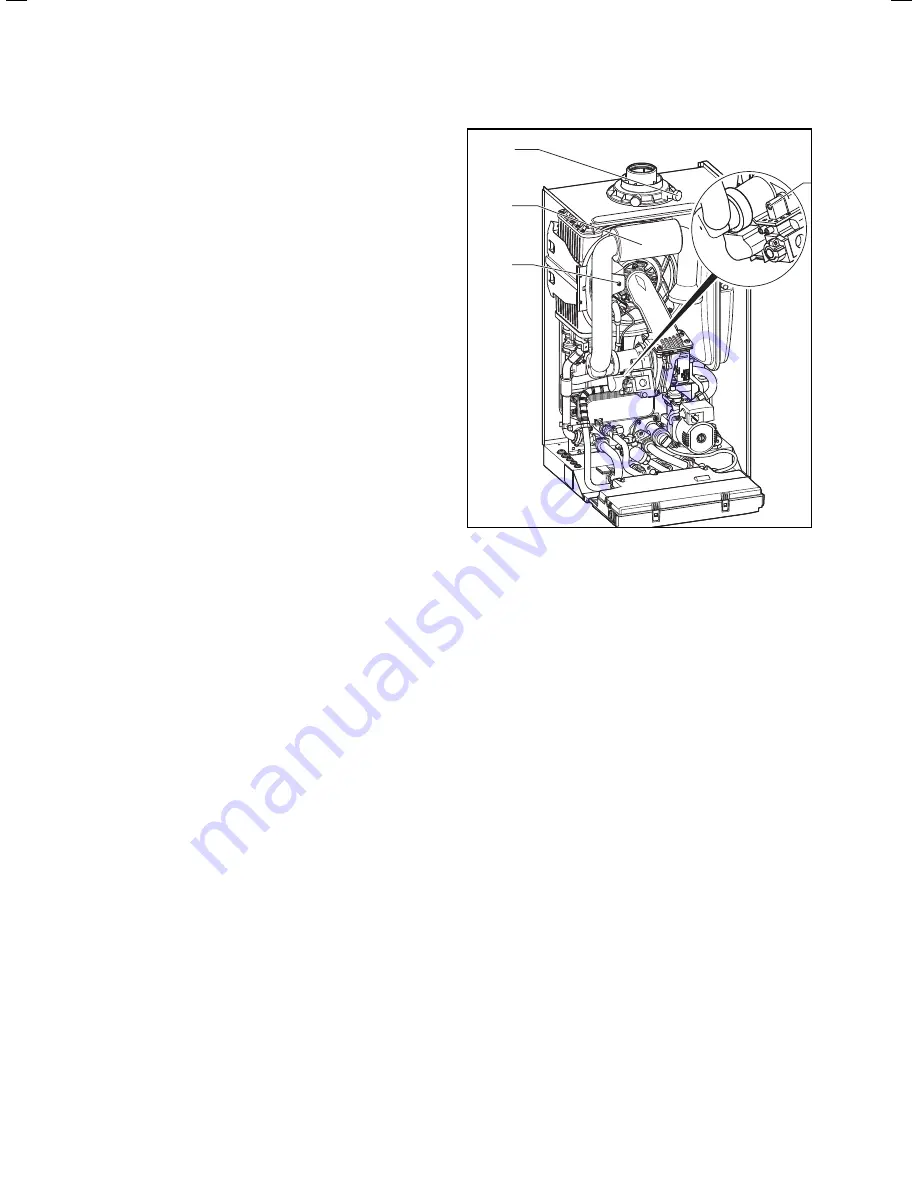

Fig. 8.1 Measuring the CO

2

concentration, specifying the air

ratio (gas setting)

Legend:

1 Main

throttle

2 Screw

3 Air

intake

pipe

4 Flue gas analysis point

i

The boiler is fitted with a flue gas analysis

point (

4

). A suitable flue gas analyser can be

connected to this point to establish the com-

bustion performance of the boiler.

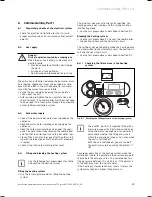

Remove the front casing.

Start the testing program P.1.

Wait at least 5 minutes until the boiler reaches its

operating temperature.

Measure the CO

2

concentration at the flue gas analy-

sis point (

4

). Compare the measured value with the

corresponding value in Table 8.1.

If all these points are as required, proceed as

described in section 7.8.5.

If one of the flue gas values is greater than the

acceptable values in Table 8.1, then proceed as

described in the following section 8.1.4.

>

>

>

>

>

>

8 Inspection and maintenance

Summary of Contents for ecoTEC plus 937

Page 1: ...For the heating engineer Installation and maintenance instructions GB IE ecoTEC plus 937 VUI...

Page 74: ...74 Installation and maintenance instructions ecoTEC plus 937 0020031552_06...

Page 76: ...76 Installation and maintenance instructions ecoTEC plus 937 0020031552_06...

Page 77: ...Installation and maintenance instructions ecoTEC plus 937 0020031552_06 77...

Page 78: ......

Page 79: ......

Page 80: ...0020031552_06 GBIE 102010 Subject to alterations...