Operation 6

0020181589_04 auroCOMPACT Installation and maintenance instructions

19

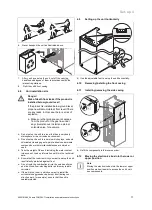

5.7.7.1 Using the auxiliary relay

1.

Connect an additional component directly to the integ-

rated auxiliary relay using the grey plug on the PCB.

2.

Connect the wiring in the same way as described in the

section "Installing the control (

→

Page 18)".

3.

To start up the connected component, select the com-

ponent using diagnostics code

D.026

, see Calling up

diagnostics codes (

→

Page 28).

5.7.7.2 Using the VR 40 ("2 in 7" multi-functional

module)

1.

Install the components in accordance with the respect-

ive instructions.

2.

Select

D.027

(

→

Page 28) to actuate relay 1 on the

multi-functional module.

3.

Select

D.028

(

→

Page 28) to actuate relay 2 on the

multi-functional module.

5.7.7.3 Actuating the circulation pump according to

requirements

1.

Connect the connection cable for the external button

using terminals 1

(0) and 6 (functional drawing) on

the X41 edge connector, which is supplied with the con-

troller.

2.

Plug the edge connector into the PCB slot X41.

3.

Press the external button to make the circulation pump

to run for five minutes.

5.7.7.4 Actuating a circulation pump with an eBUS

controller

1.

Select a hot water programme (preparation).

2.

Parametrise a circulation programme on the controller.

◁

The pump runs during the time period specified in

the programme.

6

Operation

6.1

Operating concept of the product

The operating concept and the display and setting options of

the end user level are described in the operating instructions.

An overview of the display and setting options of the installer

level can be found in the section "Overview of the menu

structure

–

Installer level" (

→

Page 45).

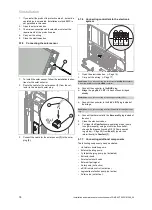

6.1.1

Calling up the installer level

Caution.

Risk of material damage caused by incor-

rect handling.

Incorrect settings at installer level may cause

damage and operating faults to the heating

installation.

▶

You must only access the installer level if

you are an approved competent person.

Note

The installer level is protected against unauthor-

ised access using a password.

1.

Press

and

("i") simultaneously.

◁

The following menu appears in the display.

2.

Use the

or

button to scroll until the

Installer

level

menu point appears.

3.

Press (

OK

) to confirm your selection.

◁

In the display, the text

Enter code

appears along

with the value

00

.

4.

Use

or

to set the value

17

(code).

5.

Press (

OK

) to confirm your selection.

◁

The installer level appears with a selection of menu

points.

6.2

Live Monitor (status codes)

Menu

→

Live Monitor

Status codes in the display provide information on the pro-

duct's current operating status.

Status codes

–

Overview (

Applicability:

Germany)

(

→

Page 51)

Status codes

–

Overview

6.3

Test programmes

As well as the installation assistants, you can also call up the

test programmes for start-up, service and troubleshooting.

Menu

→

Installer level Appliance config.

There you will find the

Check programs

(

→

Page 24), in

addition to the

Function menu

, an

Electronics self-test

and the

Gas family check

.

7

Start-up

7.1

Auxiliary service equipment

Applicability:

Germany

OR Austria

The following test and measuring equipment is required for

start-up:

–

CO

2

measuring instrument

–

Digital or U tube manometer

–

Flat blade screwdriver, small

–

2.5 mm Allen key