4

Operation

Instructions for use turboMAX pro

4

Initial checks before turning ON

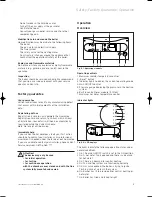

Open the service valves

• Ensure the cold water service valve is open. This can

be checked by opening a hot water tap and ensuring

water flows.

• Ensure that the service valves in the heating flow and

return (2 and 1) and the gas service valve (3) are open.

The flow, return and gas

service valves are open when the line marking

has the same direction as the pipe.

• The pressure relief valve (4) is provided for safety

reasons and must not be interfered with.

Fig. B.3: Opening service valves

Check the water contents

Fig. B.4: Checking the water level

• Check the water contents of the system on the

pressure gauge (4).

• The needle on the pressure gauge should be within

the green band (between 1 and 1.5 bar). If the needle

displays a value below 0.8 bar when the appliance is

cold, follow the instructions left by your installer to

refill the system. Alternatively, your installer should be

called to refill the system.

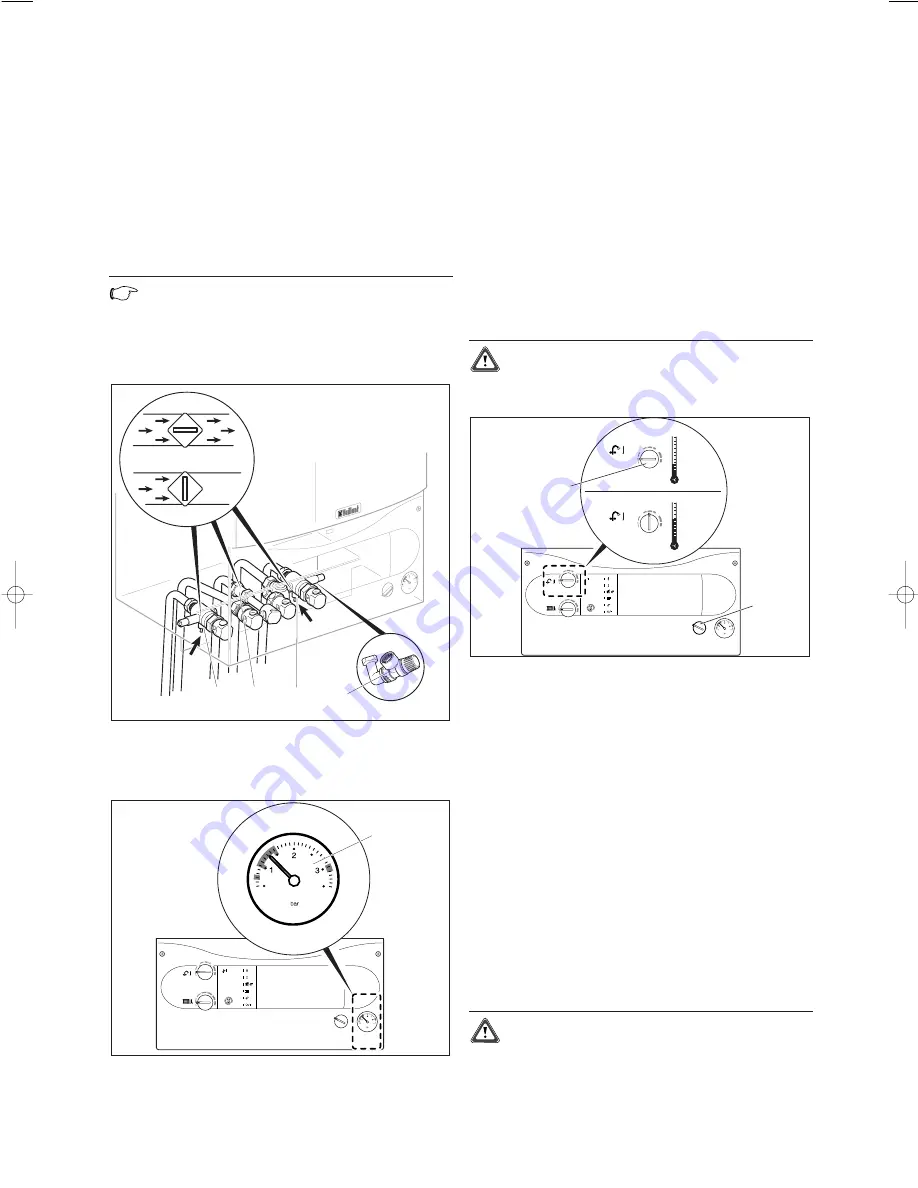

Domestic hot water operation

The boiler should only be used when the heating

system contains water. Use of the boiler without

water may cause damage to the boiler or its

components.

Fig. B.5: Domestic hot water supply

Setting the maximum domestic hot water temperatu-

re control

• Turn the main switch (1) to the „l“ position.

• The domestic hot water

temperature can be adjusted using the hot water

temperature control (2).

• Turn the control clockwise to increase the temperature

and anti-clockwise to decrease the

temperature.

As a guide for normal circumstances set the knob to the

1 o´clock position.

Note:

This control adjusts the maximum domestic hot water

temperature. If adjusting the control upwards appears

to have no effect on the temperature, then the boiler

is already operating at full output for the selected flow

rate. If hotter water is required the flow rate should be

reduced by partially closing the hot water tap.

If you live in a hard water area please do not set

the control knob above the mid (12 o´clock)

position to prevent excessiv scale formation

(fig. B.5).

I

0

C

o

C

o

1

2

I

0

4

I

0

2

3

1

4

833689_22GB_032005 09.03.2005 17:13 Uhr Seite 4