12

Operating manual atmoCRAFT

Display

Meaning

Displays of system conditions

S.30

No heat requirement from 2-point controller

S.31

Summer mode active

S.34

Frost protection heating active

S.36

No heat requirement controller from continuous

controller

S.39

Switch on "unit thermostat" terminal has interrupted

S.42

Exhaust gas flap contact on accessories is open

S.51

The unit has detected exhaust gas emission and is

within the 30 second continuous tolerance time

S.52

Appliance is within the 20-minute waiting period of the

operation block function due to exhaust gas emission

Table 4.1 Status codes and their meaning (continuation)

4.8 Troubleshooting

If you have problems with your gas boiler, you can check

the following points yourself:

No hot water, heating stays cold;

Appliance does not start:

- Is your house stop cock in the gas supply or the gas

stop on the appliance open (see Section 4.2)?

- Is the power supply switched on?

- Is the main switch on the gas boiler switched on (see

Section 4.3)?

- Is the rotary knob for setting the storage tank

temperature turned to the far left position, in other

words to frost protection (see Section 4.4)?

- Is the filling pressure of the heating system sufficient

(see Section 4.8.2)?

- Is there air in the heating system (see Section 4.8.2)?

- Is there an ignition problem (see Section 4.8.3)?

Hot water operation, no problem;

Heating does not start:

- Is there a requirement for heating from the external

controller (e.g. type VRC controller) (see Section 4.7)?

- Has an external monitor switched off the system (see

Section 4.7)?

Heating, no problem; no hot water:

- Is the hot water preparation blocked by an external

controller (see controller instructions)?

If when simultaneously depressing the buttons "

+

" and

"

-

" no hot water is shown, then the sensor is faulty or

is not connected.

Caution!

Inappropriate alterations can cause damage!

If your gas boiler still does not work properly

after you have checked the above points, you

must call a suitably qualified heating engineer

for help.

4.8.1 Faults during heating operation

In the event of a fault on the boiler, a fault code will be

shown on the display. In the case of the faults described

above you can try to resolve the fault yourself.

Caution!

In the event of other faults in the heating

system an authorised heating engineer must be

consulted to check the system.

4.8.2 Problems due to lack of water

1

2

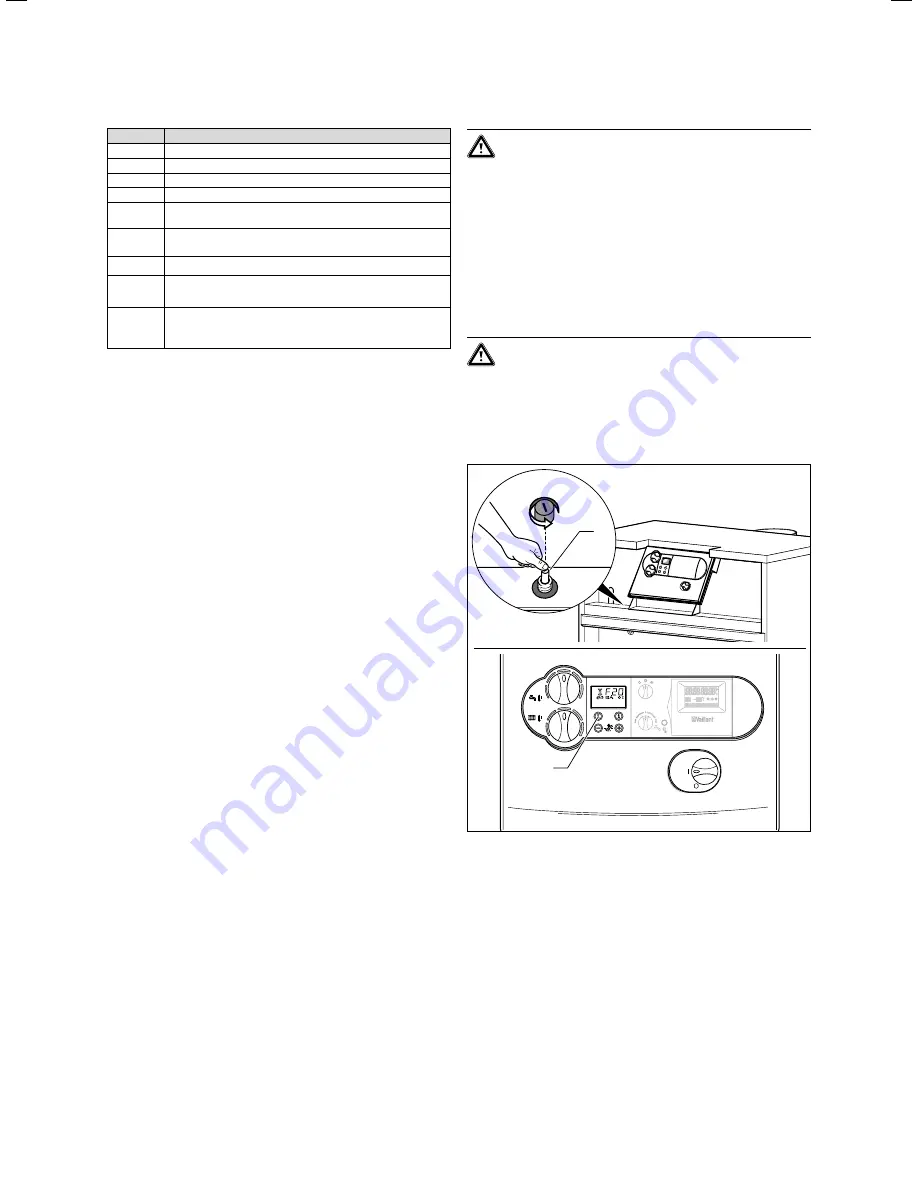

Fig. 4.12 Releasing after water shortage

The device switches to

"Fault

" if the filling pressure in

the heating system is too low. This fault is displayed by

the fault code "

F.20

".

• Remove the front cover.

• Release the STB by pushing the pin (

1

).

• Reset the electronic system by pushing the "Reset"

button (

2

).

4 Operation