9

Installation and maintenance manual atmoCRAFT

GB

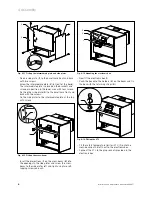

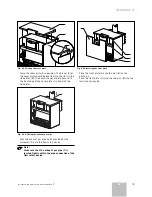

4 Assembly

4.1 Installation

site

4.1.1 Regulations concerning installation site

The approval of the relevant building regulations

authority must be obtained for the selection of the

installation site and for the characteristics of the

ventilation and exhaust gas handling systems of the

installation room.

The combustion air fed to the unit must be technically

free of chemicals which contain, e.g. fluorine, chlorine or

sulphur. Sprays, paints, solvents and cleaning materials

and adhesives contain such substances, which can,

during operation of the unit, lead to corrosion under

certain conditions, including in the exhaust gas

installation. If the installation is to take place at the site

of erection, a water pressure test at a test pressure of

5,2 bar should be performed. The equipment

manufacturer must, in this case, issue a certificate to

say that the water pressure test has been performed.

Separation of the unit from structural components of

flammable material by a specified distance is not

required. Since, at nominal heating output of the unit,

temperatures in excess of the permissible temperature

of 85 °C are not created, we recommend the clearances

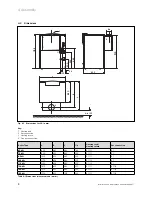

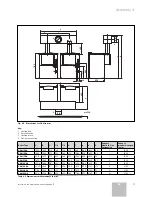

shown in Section 4.3.

Clearances in accordance with Section 4.1 to 4.3 must be

maintained for maintenance purposes.

If the boiler is to be installed on a flammable floor (e.g.

wood, PVC or similar), the boiler must be placed on an

underlay of non-flammable material.

4.1.2 Notes concerning the heating system and the

installation site

– From the blow-off line of the safety valve, there must

be a drain pipe with inlet funnel and syphon fitted by

the user to a suitable drain (connection to the waste

water system) within the installation room. The drain

must be visible!

– The safety temperature limiter fitted to the boiler also

serves as a shortage of water safety device.

– The switch-off temperature of the boiler in the event

of a malfunction is ca. 110 °C.

A suitable thermostat must be mounted in the heating

feed line by the user if plastic pipes are used in the

installation. This is required to protect the heating

installation from temperature-related damage. The

thermostat can be wired electrically into the plug

location for the plant thermostat of the Pro E system.

– In the case of installation volumes in excess of 15 l/kW

heating capacity, suitable hydraulic protection

switching must be installed.

– The boiler should be installed in a frost-protected room

in the vicinity of the exhaust gas chimney. The

permissible ambient temperature for operation of the

boiler is b 3 °C and + 45 °C.

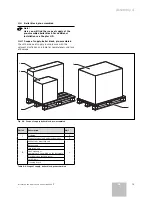

– When selecting the installation location, the weight of

the boiler, including the water contained within it,

shown in the table “Technical Data” and the type of

chimney construction must be taken into account.

Assembly 4

Summary of Contents for atmocraft

Page 1: ...VK 654 9 1654 9 atmoCRAFT DE AT GB...

Page 2: ......

Page 44: ...835553_02 DEATGB 092006...