7 Eliminating the fault

14

Installation and maintenance instructions atmoMAG 0020271943_00

6.4

Checking the gas flow pressure

Applicability:

Germany

OR Belgium

1

▶

Close the gas stopcock.

▶

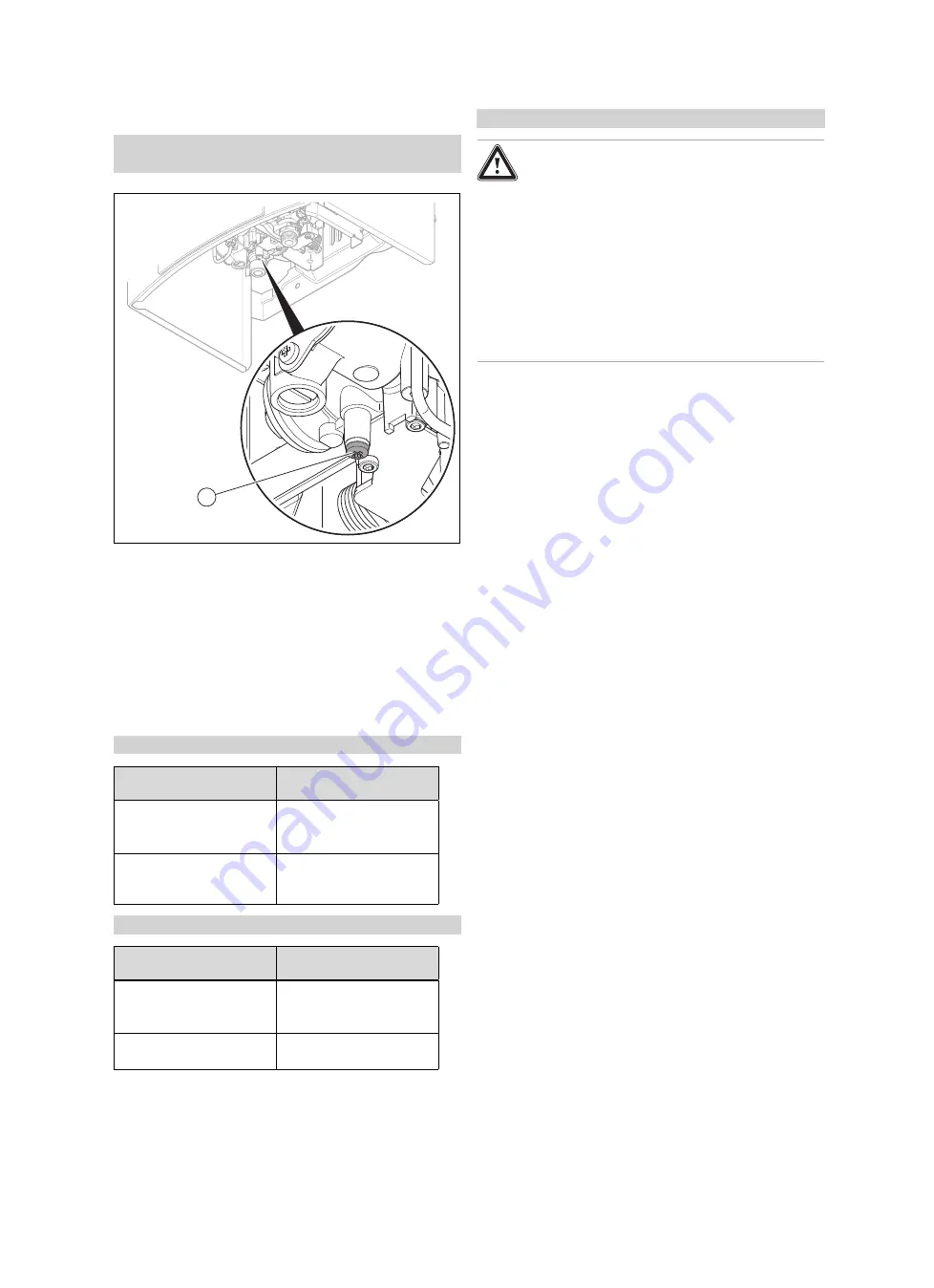

Unscrew the sealing screw

(1)

from the test nipple on the

gas valve assembly.

▶

Remove the seal.

▶

Connect a manometer to the test nipple on the gas valve

assembly.

▶

Open the gas stopcock.

▶

Start up the product in accordance with the operating

instructions and draw off domestic hot water.

▶

Measure the gas flow pressure.

Applicability:

Germany

Gas family

Permissible gas flow pres-

sure

Natural gas

G20

G25

1.7

–

2.5 kPa (17

–

25 mbar)

1.8-2.5 kPa (18-25 mbar)

Liquid gas

G31

4.25-5.75 kPa (42.5-

57.5 mbar)

Applicability:

Belgium

Gas family

Permissible gas flow pres-

sure

Natural gas

G20

G25

1.7

–

2.5 kPa (17

–

25 mbar)

2.0-3.0 kPa (20-30 mbar)

Liquid gas

G31

2.5

–

4.5 kPa (25

–

45 mbar)

Conditions

: Gas connection pressure not in the permissible range

Danger!

Risk of material damage and operating

faults caused by incorrect gas flow pres-

sure.

If the gas flow pressure lies outside the per-

missible range, this can cause operating

faults in and damage to the product.

▶

Do not make any adjustments to the

product.

▶

Check the gas installation.

▶

Do not start up the product.

▶

If you are unable to remedy the fault, contact the gas

supply company.

▶

Close the gas stopcock.

▶

Remove the pressure gauge.

▶

Position the seal on the sealing screw.

▶

Screw the sealing screw

(1)

into the test nipple on the

gas valve assembly again.

▶

Open the gas stopcock.

▶

Check the test nipple for gas tightness.

6.5

Checking leak-tightness

▶

Check the gas pipe and the hot water circuit for leak-

tightness.

▶

Check that the flue system has been installed correctly.

6.6

Handing the product over to the operator

1.

Explain to the operator how the safety devices work and

where they are located.

2.

Inform the operator how to handle the product. Answer

any questions the operator may have.

3.

Draw special attention to the safety instructions which

the operator must follow.

4.

Inform the operator of the necessity to have the product

maintained according to the specified intervals.

5.

Pass all of the instructions and documentation for the

product to the operator for safe-keeping.

6.

Inform the operator about measures taken to ensure the

supply of combustion air and flue gas guiding, and in-

struct the operator that he must not make any changes.

7

Eliminating the fault

▶

Use the table that is included in the appendix to eliminate

the fault.

▶

After each time you eliminate a fault, check that the flue

gas sensor is working without any problems.

▶

If you are unable to eliminate the fault, contact Vaillant

Customer Service.

8

Inspection and maintenance

▶

Adhere to the minimum inspection and maintenance in-

tervals. The inspection may require maintenance to be