5.3 Collector

installation

1

2

3

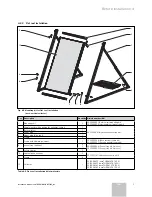

Fig. 5.2 Preparing the frame

• Open the frames.

a

Caution!

Observe Table 5.1 for determining the

required load!

With screwed connection on the roof

• Fix the lower telescopic section with bolt

and safety clip.

2

1

2

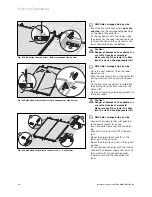

Fig. 5.3 Mounting the gravel trays

If gravel trays are used:

• Slide the gravel tray (

1

) on the floor sec-

tion.

Collector

position

Number of gravel trays per frame

w

2

s

3

Table 5.3 Number of gravel trays

• Apply the safety clamps (

2

) from the top in

the floor sections (2 x frame) to fix the

gravel tray.

• Fix the lower telescopic section with bolt

and safety clip.

60°

45°

30°

1

2

Fig. 5.4 Frame assembly

• Insert the telescopic sections into each

other, until the holes of the desired angular

position are placed one above the other.

h

Note

You can choose 30°, 45° or 60°

(standard: 45°).

• Insert the retaining pin into the corre-

sponding hole (

1

).

• Fix the retaining pin with the safety clip (

2

).

Installation manual auroTHERM 0020057143_02

12

5 Flat roof installation