3

Installation manual flue pipe for ecoCRAFT 0020058722_03

1

Notes on the documentation

The following information is intended to help you

throughout the entire documentation. Further docu-

ments apply in combination with this installation manu-

al.

We accept no liability for any damage caused by fail-

ure to observe these instructions.

Other applicable documents

For the heating engineer:

Installation instructions ecoCRAFT

No. 0020055744

1.1

Lodging and storage of the documents

Pass this installation manual as well as any other appli-

cable documents and auxiliary material if necessary to

the system operator, who will store them so that the

manuals and auxiliary material are available when re-

quired.

1.2 Symbols

used

Please observe the safety instructions in this installation

manual for the installation of the flue pipes!

d

Danger!

Immediate risk of serious injury or death!

a

Caution!

Potentially dangerous situation for the product

and environment.

h

Note

Useful information and notes.

• Symbol for a necessary task

1.3

Applicability of the manual

This installation manual applies exclusively to the

Vaillant appliances listed in the other applicable docu-

ments.

2

Description of the appliance

2.1 CE

label

The ecoCRAFT VKK GB 806/3-E-H, VKK GB 1206/3-E-H,

VKK GB 1606/3-E-H, VKK GB 2006/3-E-H,

VKK GB 2406/3-E-H and VKK GB 2806/3-E-H gas fired

condensing boilers have been certified in accordance

with the EU Gas Equipment Directive 90/396/EWG as

heating boiler systems with an associated flue gas in-

stallation and as a boiler of type C63.

2.2 Intended

use

Vaillant gas-fired high efficiency boilers ecoCRAFT

VKK GB 806/3-E-H, VKK GB 1206/3-E-H, VKK GB

1606/3-E-H und VKK GB 2006/3-E-H,

VKK GB 2406/3-E-H and VKK GB 2806/3-E-H are con-

structed in accordance with state of the art technology

and recognised safety regulations.

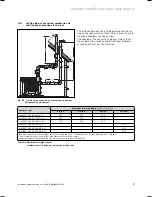

The air/flue gas pipe is designed to remove exhaust gas

and to supply combustion air. In case of improper non-

conventional use of air and exhaust pipes in connection

with appliance types, damage can be caused to the

health and body of the user and others respectively

other devices or material assets can be affected.

The dimensioning of the air/flue gas pipes tested with

the respective high efficiency boiler must be carried out

by means of the tables in the following chapters.

Any other or additional use is considered to be improper

and will relieve the manufacturer or supplier of any re-

sponsibility or liability for damage that may result. In

such cases the risk is borne solely by the technician car-

rying out the work and the user. Intended use also in-

cludes the observance of the other applicable docu-

ments.

3 Safety

instructions/regulations

3.1 Safety

instructions

Before installing the flue pipes you must inform the

local gas supply company and the regional chimney

sweep.

d

Danger!

Danger of poisoning from exhaust gas leakage if

installed incorrectly!

The flue gas system may only be installed by a

suitably qualified heating engineer. He will also

assume responsibility for proper installation.

Furthermore, the rules, regulations and guide-

lines mentioned in this installation manual are

to be observed.

Danger!

Risk to life from poisoning as a result of escap-

ing flue gases!

All openings in the flue pipe that can be opened

for inspection purposes must be closed before

start-up and during operation. The openings

may only be opened by a technician.

Danger!

Danger of suffocation!

The room in which the appliance is situated

shall be designed and the appliance installed

within it as specified in BS 6644.

Notes on the documentation 1

Description of the appliance 2

Safety instructions/regulations 3