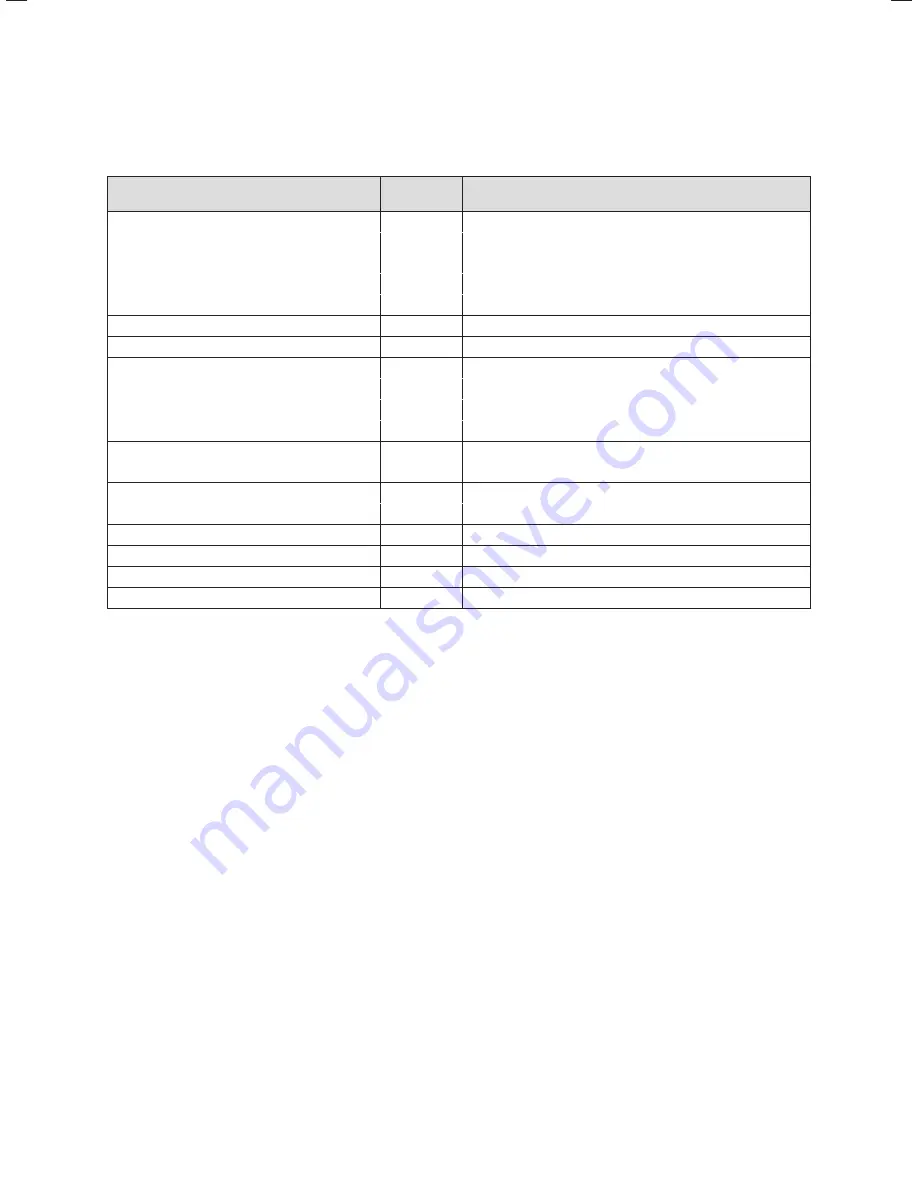

Technical data

20

ecoLEVEL installation and maintenance instructions 0020029316_01

12

12 Technical

data

Technical data

Units

ecoLEVEL

Design

Appliance for wall-mounted installation

Nominal capacity

l

0.5

Supply voltage

V

230

Max. current consumption

A

1

Frequency

Hz

50

Max. nominal output

W

25

Max. feed height

m

4

Dimensions Height

mm

150

Width

mm

175

Depth

mm

100

Weight when filled with water

kg

1.8

Inlet hose (max. outside diameter)

mm

24

Drain hose (min. inner diameter)

mm

10

Water inlet temperature

°C

1 - 60

Ambient temperature

°C

5 - 60

Safety

Radio-shielded, non-interacting with the mains supply

Safety cut-out switch

5 mA - 4 A; 230 V

Level of protection in accordance with EN 60529

IP 44

Approved for individual units

kW

up to 45

12.1 Technical data

Summary of Contents for ecoLEVEL

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ...0020029316_01 GBIE 102012 Subject to change Manufacturer Supplier ...