Instructions for Use, Installation and Servicing ecoMAX pro

15

7 Flue

8 Installation preparation

1)

In addition, the terminal should not be nearer than 150mm to an opening

in the building fabric formed for the purpose of accommodating a built-in

element such as a window.

2)

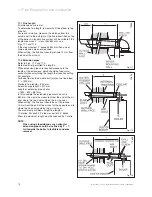

Dimension B,C and D; These clearances may be reduced to

25 mm without affecting the performance of the boiler. In order to ensure

that the condensate plume does not affect adjacent surfaces the terminal

should be extended as shown in Fig 7.4.

3)

Dimension F; This clearance may be reduced to 25 mm without affecting

the performance of the boiler. However, in order to ensure that the con-

densate plume does not affect adjacent surfaces a clearance of 300 mm is

preferred.

4)

BS 5440-1 It is recommended that a fanned flue terminal should be posi-

tioned as follows:

a) at least 2m from an opening in a building directly opposite, and

b) so that the products of combustion are not directly directed to discharge

across a boundary. For IE, recommendations are given in the current edition

of IS 813.

TERMINAL POSITION

mm

A

1)

Directly below an opening, above an opening

or horizontal to an opening i.e. air brick, opening

window or other, etc

300

B Below gutters, soil pipes or drain pipes

75

2)

C Below eaves

200

2)

D Below balconies

200

2)

E From vertical drain pipes and soil pipes

25

F From internal or external corners

300

3)

G Above ground, roof or balcony

300

H From a surface facing a terminal

600

4)

I

From a terminal facing a terminal

1200

K Vertically from a terminal on the same wall

1500

L Horizontally from a terminal on the same wall

300

M Distance from adjacent wall for vertical Flue

500

balcony/eaves

flue extended to

clear any overhang

flue adequately

supported

gutter

7.3 Internal Flue Installation

The flue can be installed from inside the building when

access to the outside wall face is not practicable.

7.4 Flue Options

There are various flue systems to choose from, as

follows:

• Vertical air/flue duct and terminal

303 900

• Air/flue duct extension (470 mm)

303 902

• Air/flue duct extension (970 mm)

303 903

• Air/flue duct extension (1970 mm)

303 905

• Telescopic air/flue duct extension

(440 mm - 690 mm)

303 906

• 87° elbow

303 910

• Two 45° bends

303 911

• Standard horizontal air/flue duct

with elbow and terminal (800 mm)

303 930

Additional accessories are available.

8 Installation preparation

8.1 Unpacking of Boiler

Stand the boiler carton upright.

Cut and remove the securing straps and lift off the carton

sleeve. Place aside the flue adaptor and connections

pack until required.

Carefully lay the boiler on its back, remove the two front

casing panel securing screws and lift off the panel from

two retaining lugs, see diagram 8.1.

Remove the two inner casing panel securing screws

at the bottom front of the panel, then lift off the two

retaining lugs, see diagram 8.2.

8.2 Using boiler template

Fix the paper template to the wall ensure that the

template is vertical.

The template shows

• The position of the fixing holes for the boiler mounting

bracket (1).

• The position of the connections.

• The position of the flue exit hole.

Mark the position of the top hanging bracket fixing holes.

Drill 2 holes to accept the wallplugs/screws supplied for

the hanging bracket.

NOTE:

Use alternative fixing holes where necessary.

Fig 7.4

12677

Fig 8.1

12678