13

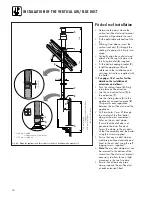

INSTALLATION OF THE HORIZONTAL AIR/FLUE DUCT (TOP OUTLET)

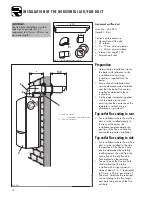

• Once the position of the flue exit

hole has been determined, the

hole should be cut through the

wall using a core drill of 125 mm

diameter.

Note: If access can be gained to

the proposed flue exit point from

outside the dwelling, the hole can

be cut with a 107 mm core drill

and the flue external wall seal

fitted from outside the dwelling.

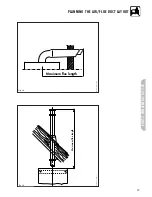

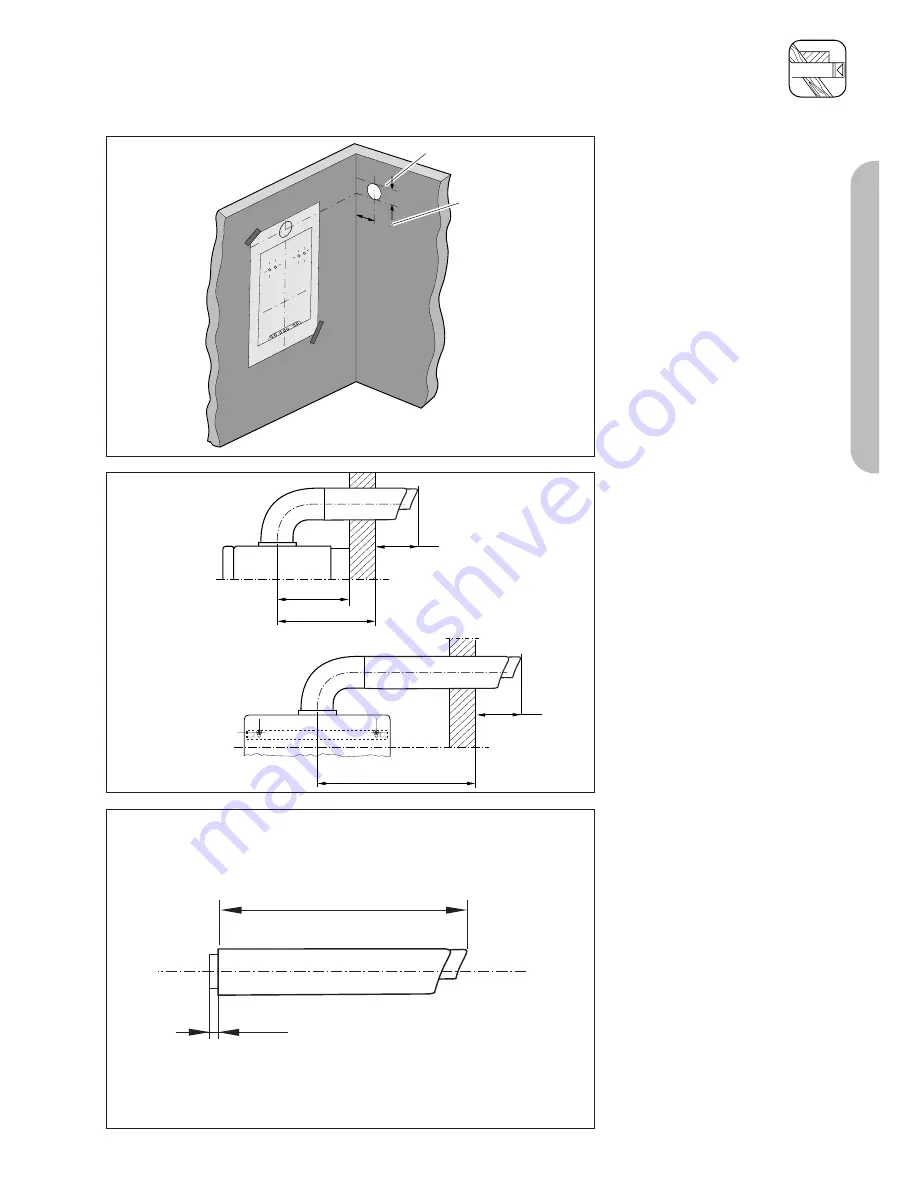

• Measure the distance from the

outside face of the wall to the

centre of the fan outlet on the

boiler.

This is dimension A.

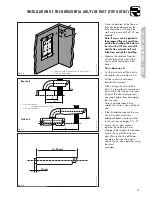

• Cut the air duct and flue duct to

the lengths shown in figure 3.4.

• All flue sockets should point

towards the terminal.

• When cutting the air and flue

ducts it is important to remove any

burrs with a file, this ensures easy

fitting of the ducts and prevents

any rough edges from damaging

the flue seals.

Care should be taken not to

scratch the white surface of the air

duct.

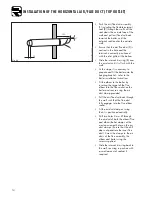

• If the installation requires the use

of air/flue duct extensions,

additional bends or elbows refer

to the sections on pages 20 – 21.

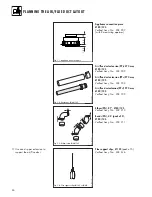

• Secure the air duct sections

together by drilling a 3 mm

diameter hole through the location

hole in the end of the outer air

duct. (Ensure that the drill does

not pierce the inner flue duct).

Secure the air ducts together using

the screw

provided.

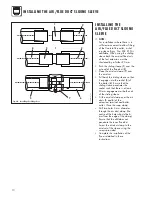

1

2

*

* = 190 mm

Fig. 3.2

LAS Euro B/S 077/1

150

A

B

A

150

Fig. 3.3

LAS Euro B/S 078/0

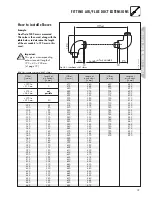

A + 45 mm

13 mm

Fig. 3.4

LAS Euro B/S 076/0

Rear exit

Side exit

PA

R

T 1 CONCENTRIC 60/100

*

*

= 190 mm ecoMAX

combination and system boilers

*

= 176 mm ecoMAX pro

*

= 190 mm ecoMAX combination and system boilers

*

= 176 mm ecoMAX 400