Supplied By www.heating spares.co Tel. 0161 620 6677

15

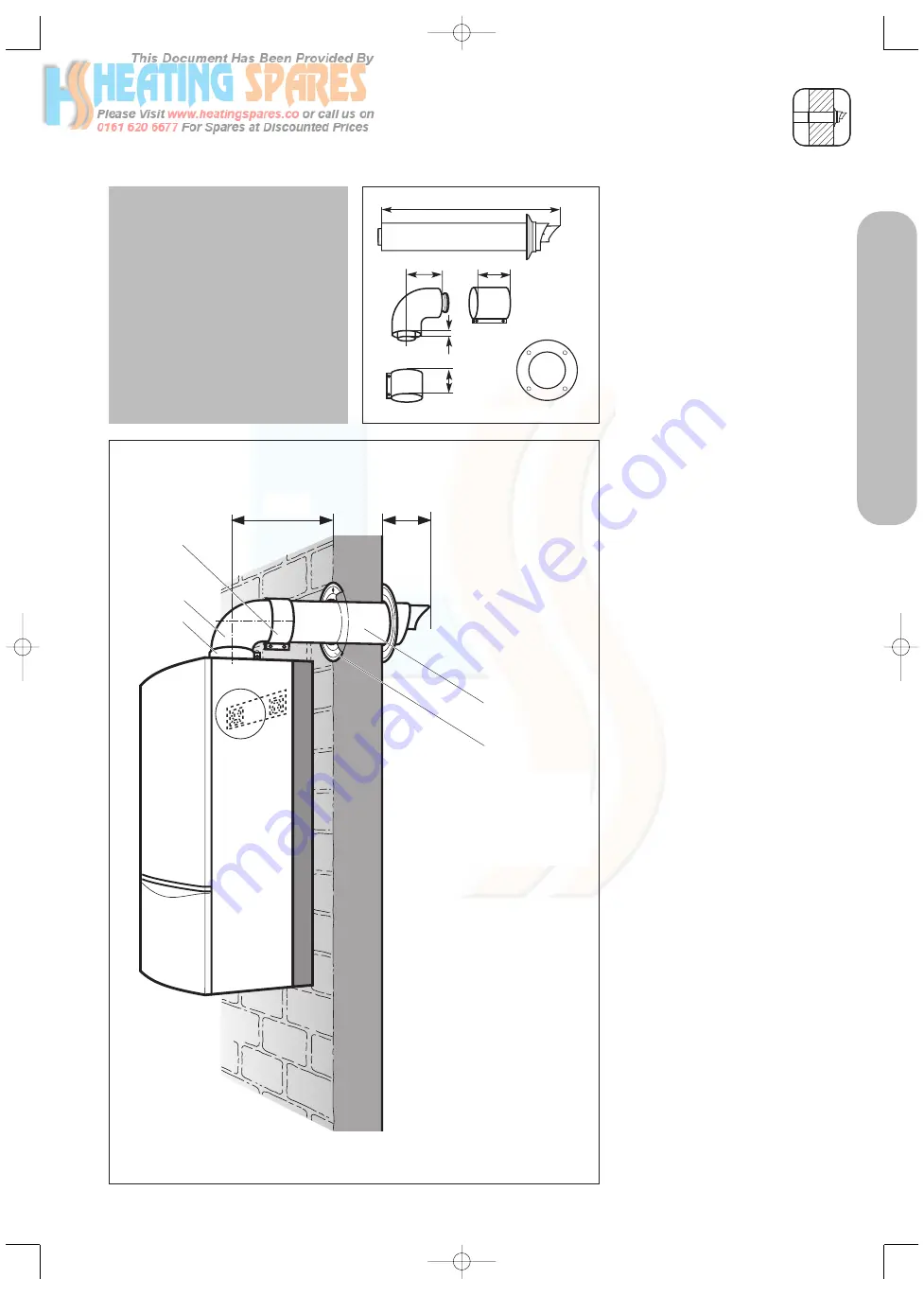

INSTALLATION OF THE HORIZONTAL AIR/FLUE DUCT

Horizontal air/flue duct

Accy No.: 303 933

(Length 0.75 m)

Contents of the accessory:

• Horizontal air/flue duct

• 87° elbow

• 1 x 48 mm air duct clamp

• 1 x 30 mm air duct clamp

• Internal trim ring Ø 100

• External wall seal.

Fig. 3.7: Horizontal air/flue conduit

Preparation

• Determine the installation site for

the boiler with reference to the

installation and servicing

instructions supplied with the

boiler.

• Ensure that all installation and

service clearances are available

and that the boiler flue can be

installed as detailed in these

instructions.

• Fix the paper template, supplied

with the boiler, to the wall

ensuring that the centreline of the

template is vertical using a

plumbline or spirit level.

Top outlet flue exiting to rear

• For installations where the air/flue

duct is to be installed directly to

the rear of the boiler, the

installation template details the

position of the flue exit hole for

horizontal top outlet installation.

Top outlet flue exiting to side

• For installations where the air/flue

duct is to be installed to the side,

the position of the flue exit hole

can be determined by carefully

levelling across the wall from the

centre line of the air/flue duct hole

marked on the template (fig. 3.9).

• The position of the flue exit hole

should allow the flue to be

installed with a slight upward

slope of about 3° ± 1° (equivalent

to 50 mm ± 20 mm per metre of

flue duct). Calculate the required

rise according to the flue length

and mark the position of the flue

exit hole.

30

13

754

48

65

3

*

87

5

4

2

1

Fig. 3.8

LAS Euro B/S 072/0GB

*

*

= 190 mm ecoMAX

combination and system boilers

*

= 176 mm ecoMAX pro and ecoTEC plus

open vent

*

= 125 mm ecoTEC plus

system & combination

IMPORTANT:

The air/flue duct is not concentric

and the air duct has a slope of 1.5°

(if the air flue duct is not cut). The

hole through the wall can therefore

be drilled horizontally with no slope.

Where extensions are used, these

must be installed with a slope at 3° ±

1° (equivalent to 50 mm ± 20 mm

rise per metre length) to ensure that

condensate dows not remain in the

sleeve.

PAR

T 1 CONCENTRIC 60/100

834449_09GB_082006.qxd 10.08.2006 12:20 Seite 15

Summary of Contents for ecoTEC plus 612

Page 54: ...Supplied By www heating spares co Tel 0161 620 6677...

Page 55: ...Supplied By www heating spares co Tel 0161 620 6677...

Page 56: ...Supplied By www heating spares co Tel 0161 620 6677 839592_05 GB 08 2006...

Page 122: ...Supplied By www heating spares co Tel 0161 620 6677...

Page 124: ...Supplied By www heating spares co Tel 0161 620 6677 0020010870 01 GB 03 2006 2...

Page 142: ...Supplied By www heating spares co Tel 0161 620 6677 0020010870 01 GB 03 2006 20...

Page 162: ...Supplied By www heating spares co Tel 0161 620 6677 Notes 0020010870 01 GB 03 2006 40...

Page 163: ...Supplied By www heating spares co Tel 0161 620 6677...

Page 179: ...Supplied By www heating spares co Tel 0161 620 6677 15 Instructions for use ecoTEC...

Page 180: ...Supplied By www heating spares co Tel 0161 620 6677 16 Instructions for use ecoTEC...

Page 181: ...Supplied By www heating spares co Tel 0161 620 6677 20 C 20 C 15 C 5 C bar bar VRT VRC i F P...

Page 182: ...Supplied By www heating spares co Tel 0161 620 6677...

Page 183: ...Supplied By www heating spares co Tel 0161 620 6677 19 Instructions for use ecoTEC...

Page 184: ...Supplied By www heating spares co Tel 0161 620 6677 838402_04 GB 08 2006...