Installation 5

0020261188_00 ecoTEC plus Installation and maintenance instructions

15

product before you carry out the gas leak-

tightness test.

▶

If, during gas leak-tightness tests, you

have closed the gas stopcock that is in-

stalled upstream of the product, relieve

the gas line pressure before you open this

gas stopcock.

▶

Do not reduce the gas pipe dimension downstream of the

gas meter.

▶

Maintain the dimension right up to the product.

▶

Select the correct gas stopcock.

▶

Remove the residues from the gas pipe by blowing

through the gas pipe beforehand.

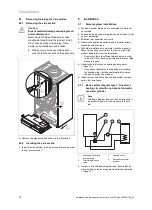

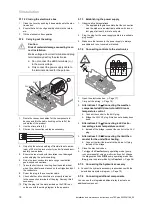

A

B

1

C

▶

Undo the press connection

(A)

.

▶

Install an approved gas stopcock at the connection

(1)

.

▶

Install the unit on the gas pipe at the product's outlet

(B)

by tightening the compression fitting

(C)

.

▶

Install the gas pipe such that it is free from mechanical

stress in accordance with the recognised rules of techno-

logy.

▶

Purge the gas pipe before start-up.

5.5.2

Checking the gas line for leak-tightness

▶

Check the entire gas line properly for leak-tightness.

5.5.3

Hydraulic connection

Caution.

Risk of material damage caused by corro-

sion

Due to non-diffusion-tight plastic pipes in the

heating installation, air gets into the heating

water. Air in the heating water causes corro-

sion in the heat generator circuit and in the

product.

▶

If you use non-diffusion-tight plastic pipes

in the heating installation, ensure that no

air gets into the heat generator circuit.

Note

In order to keep heat losses to a minimum, we

recommend that you provide heat insulation for

the water pipe spigots on the product's outlet and

on the installation.

▶

If you are using plastic pipes in the heating installation,

install a safety cut-out in the heating flow.

–

The safety cut-out is required to protect the heating

installation against temperature-related damage if a

fault occurs.

▶

Connect a control or a safety cut-out to the electronics.

(

→

Page 18)

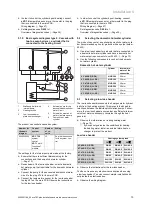

5.5.3.1 Connecting the heating flow and heating

return

A

B

C

D

1.

Attach the nut to the connection in accordance with

steps

(A)

to

(D)

.

1

10

11

12

9

7

8

2

3

4

5

6

2.

Assemble the heating return connection as shown by

numbers

(1)

to

(6)

.

3.

Assemble the heating flow connection as shown by

numbers

(7)

to

(12)

.