26

Air/flue pipe installation manual 0020308120_02

1

Danger!

Risk of poisoning due to escaping flue

gas.

When disconnecting the pipes, flue gases

may escape.

▶

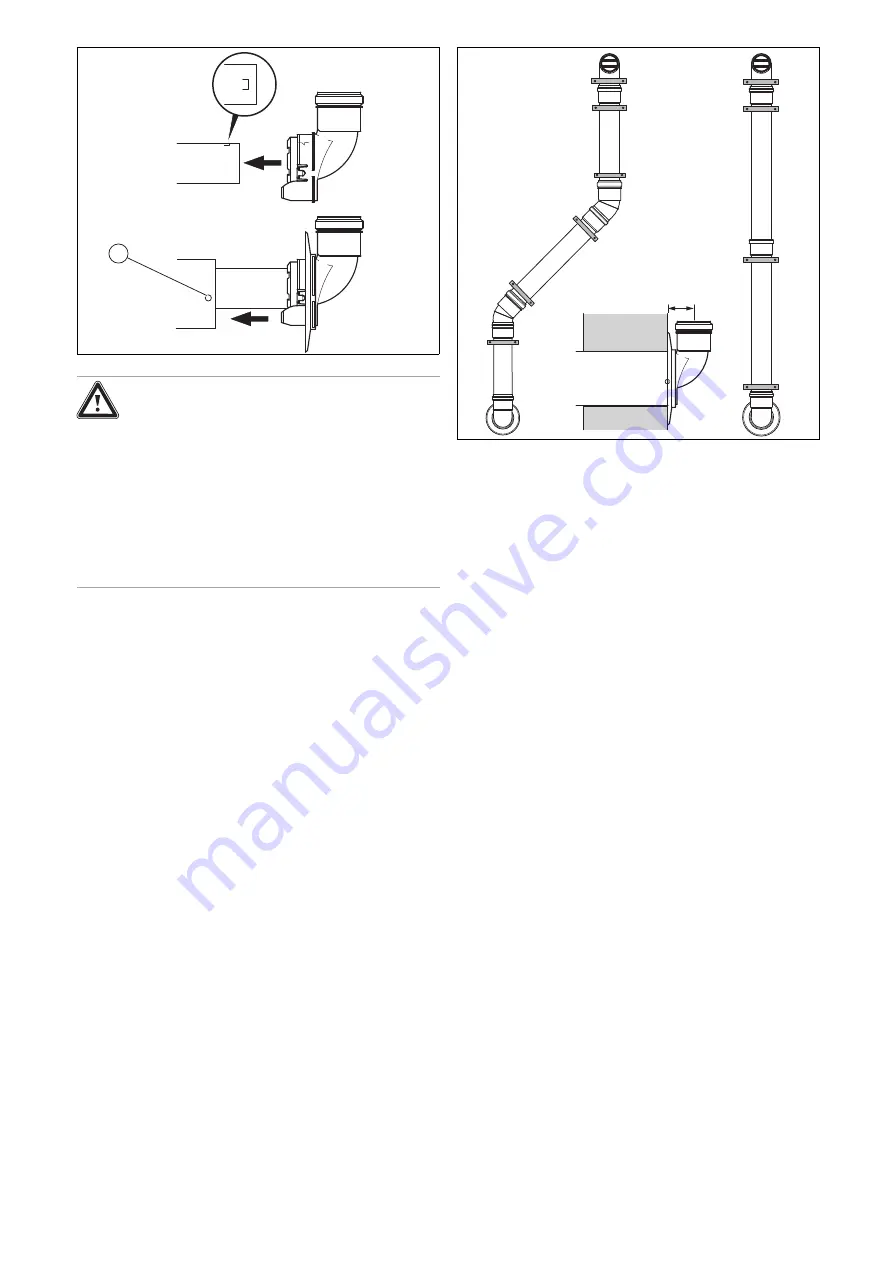

Ensure that the latching lug on the upper

side of the terminal securely snaps into

place in the flue pipe's recess.

▶

Ensure that the seal is positioned cor-

rectly.

2.

Push the new variable terminal onto the flue pipe so

that it snaps into place.

3.

Slide the flue pipe, together with the terminal, back into

the air pipe.

–

The air pipe's seam must lie at the top.

4.

Carefully slide the flue pipe back into the sleeve of the

pipe or elbow located behind it.

5.

Make sure that the two latching lugs

(1)

snap into

place.

6.

Install the wall seal on the variable terminal.

7.

Install the extensions on the variable terminal.

5.8.5.4 Installing extensions

1.

Install the flue system from the wall connector to the

flue outlet.

–

Allow expansion space of 1 cm in each sleeve.

–

Ensure that all pipe joints are absolutely leak-tight.

55

2.

Secure the extensions to the wall using the pipe

clamps.

–

Use one pipe clamp for each extension directly

beside the sleeve.

–

Upstream of each elbow, install another pipe clamp

on the extension.

–

Secure the 87° elbow with bird-guard grille using a

separate pipe clamp.

Summary of Contents for ecoTEC plus VU Series

Page 1: ...en Air flue pipe installation manual ecoTEC plus VU VUW VUI 0020308120_02 29 09 2022...

Page 57: ......

Page 58: ......

Page 59: ......