Filling the heating and heat source circuit

40

Installation instructions geoTHERM 0020051574_04

6

The brine fluid consists of water mixed with a heat transfer

fluid concentrate. We recommend that you add propylene

glycol (alternatively: ethylene glycol) with corrosion-inhibit-

ing additives.

The brine fluids that may be used differ greatly from region

to region. Please find out about this from the authorities

responsible.

Only the following brine fluids are authorised by Vaillant for

operation of the heat pump:

– Aqueous solution with 30 %

±

1 % vol. ethylene glycol

– Aqueous solution with 33 %

±

1 % vol. propylene glycol

– Aqueous solution with 30 %

±

1 % vol. ethanol

– Ready-to-use potassium carbonate/water solution

b

Caution!

Risk of damage caused by leaking.

If external passive cooling is installed and if

you use potassium carbonate as a compo-

nent of the brine fluid, this may lead to

interactions with the sealing plastics that

are used in the mixer valve.

>

If external passive cooling is installed,

you must only use ethylene glycol, pro-

pylene glycol or ethanol as a component

of the brine fluid.

This means that the brine fluid has frost protection

of - 15 °C.

A DN 40 collector hose has a capacity of approx. 1 litre per

continuous metre.

>

Use a sufficiently large mixing container.

>

If you use the Vaillant heat transfer fluid concentrate:

Mix 1.2 % propylene glycol with water at a ratio of 1 : 2.

If you use other heat transfer fluid concentrates:

Mix the water and the frost protection agent to the pre-

scribed concentration.

>

Mix each mixing batch carefully.

>

Check the mixture ratio of the brine fluid. Vaillant recom-

mends the use of a refractometer for this purpose.

b

Caution!

The function will be impaired if the brine

pipe system is contaminated.

>

When filling and flushing the system, use

a dirt filter before the filling pump. By

doing this, you ensure that dirt from

wear is completely removed from the

pipes of the brine circuit and this guaran-

tees long-lasting trouble-free operation

of the pump.

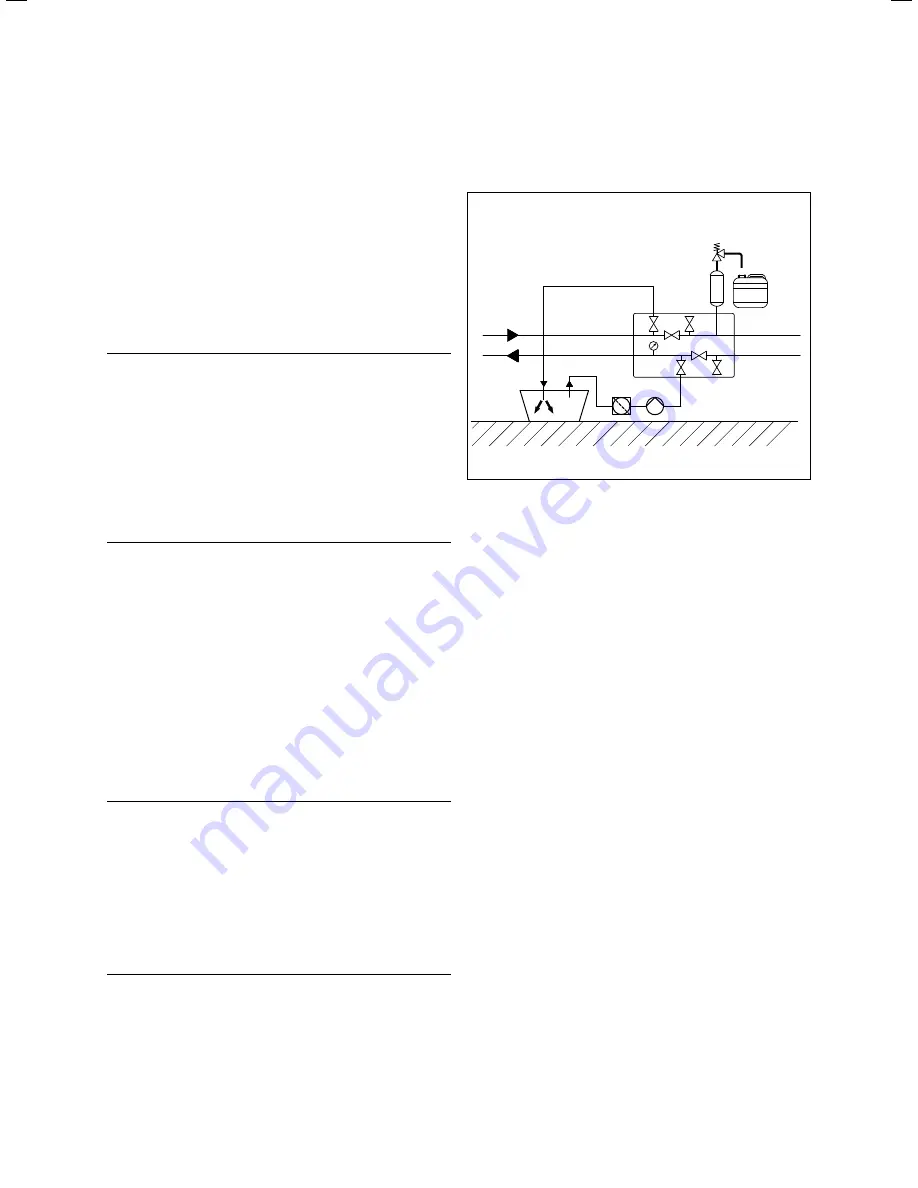

6.3.2 Filling and bleeding the outer part

of the brine circuit

66

64

48

56

70

72

62

57

42a

63

61

65

A

B

C

D

67

33

6.1 Filling and bleeding the outer part of the brine circuit

Key to Fig. 6.1 - 6.3

33

Dirt filter

42a Expansion relief valve

48

Pressure gauge

56

Heat pumps for brine filling unit

57

Brine expansion tank

61

Stop valve

62

Stop valve

63

Stop valve

64

Stop valve

65

Brine collecting tank

66

Brine container

67

Filling pump

70

Stop valve

72

Stop valve

A

Fig. 5.8, Pos. 3

B

Fig. 5.8, Pos. 4

C

From the heat source to the heat pump

D

From the heat pump to the heat source

>

Close the stop valves (

63

) and (

64

).

>

Connect the filling pump’s pressure line (

67

) to the stop

valve (

70

).

>

Connect a hose that leads to the brine fluid to the stop

valve (

61

).

>

Open the stop valves (

61

) and (

70

).

>

Start the filling pump (

67

) in order to fill the brine circuit

with the brine fluid from the brine container (

66

) via the

dirt filter (

33

).

>

Allow the filling pump (

67

) to run until there is no air in

the brine fluid that escapes from the hose at the stop

valve (

61

).

>

Close the stop valve (

70

).

>

Switch off the filling pump and close the stop valve (

61

).

>

Remove the hoses from the stop valves (

61

) and (

70

).

The stop valves (

63

) and (

64

) must remain closed.