Adapting the appliance to the heating system

Installation instructions geoTHERM 0020051574_04

73

9

9.4.2

Energy balance control

(hydraulics diagram 1 or 3)

When you have installed a heating system according to the

hydraulics diagram examples for hydraulics diagram 1 or 3

(

¬

Ch. 5.1

and

¬

Ch. 5.3

)

the controller performs an energy

balance adjustment.

For economical and fault-free operation of a heat pump, it

is important to regiment the starting of the compressor.

The start-up of the compressor is the point at which the

highest loading on the power mains occurs. With the help of

the energy balance controller it is possible to minimise

starts of the heat pump without compromising the comfort

of a pleasant room atmosphere.

As with other weather-controlled heating controllers, the

controller determines a supply set target temperature by

capturing the outside temperature by means of a heating

curve. The energy balance is calculated on the basis of this

flow actual temperature and the flow target temperature,

and the difference is measured every minute and added:

1 degree minute [°min] = 1 K temperature difference in the

course of 1 minute

For a given heat deficiency (freely selectable in the control-

ler (

Menu C2

) (

¬

Tab. 9.6

)

“Compr. start off”), the heat

pump starts and does not switch off again until the amount

of heat supplied is equal to the heat deficiency.

The larger the preset negative numerical value is, the

longer the periods for which the compressor is kept running

or at standstill.

i

If you have connected a VR 90 remote control

unit, you must not configure it as a thermostat

controller, otherwise the benefits of energy bal-

ancing will be lost.

9.4.3

Flow target temperature control

(hydraulics diagram 2, 4 or 10)

If you have installed a heating system according to the

hydraulics diagram example

for hydraulics diagram 2, 4 or 10

(

¬

Ch.

5.2

,

5.4

and

5.5

)

,

the controller performs a flow tar-

get temperature adjustment.

The buffer tank is controlled depending on the supply set

target temperature. The heat pump heats when the tempera-

ture of the VF1 flow temperature sensor of the buffer tank is

lower than the target temperature. It heats for as long as it

takes the return temperature sensor RF1 of the buffer tank to

reach the target temperature plus 2 K.

9.5 Controller

structure

The

basic display

can be seen as a

graphics display

. This

is the starting point for all available menus.

Controller operation is described in detail in the

¬ operat-

ing instructions

.

If, when setting values, you do not activate any adjuster for

15 minutes, the basic display will automatically reappear.

The controller structure has three levels:

The

operator level

is intended for the operator (

¬ operat-

ing instructions

).

The

code level

(heating engineer level) is reserved for heat-

ing engineers and is protected against accidental adjust-

ment by means of a code input.

If no code is entered, i.e. the code level is not enabled,

although the following parameters can be displayed in the

individual menus, it is not possible to amend values.

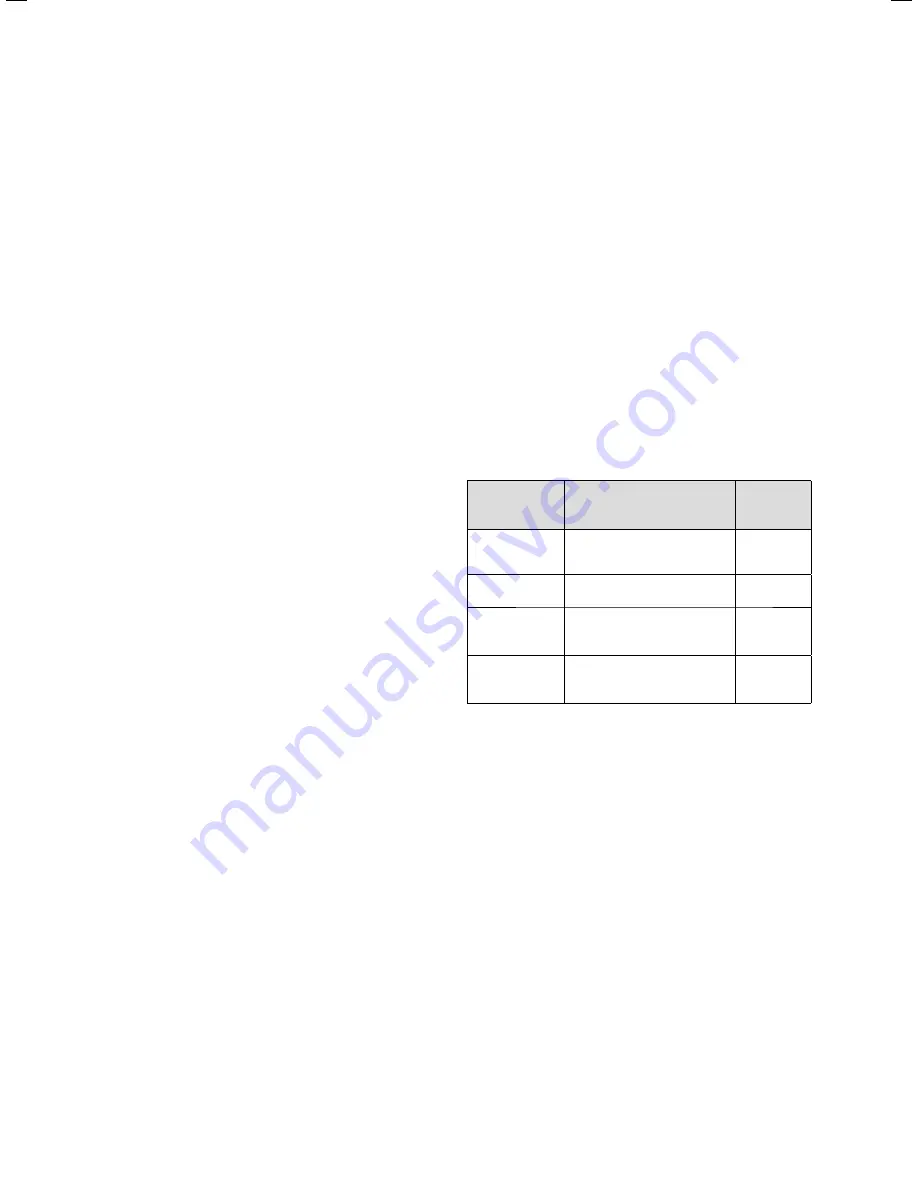

The menus are divided into four areas:

Menu areas

Description

Description

in section

C 1 to C11

Setting parameters of the heat

pump functions for heating cir-

cuits

9.7.1

D1 to D5

Operate and test the heat

pump in diagnosis mode

9.7.2

I1 to I5

Call up information on the heat

pump settings

9.7.3

A1 to A10

Call up the wizard for installing

the heat pump

9.7.4

9.3 Menu areas

The third level contains functions for optimising the heating

installation and can be set by heating engineers only via

vrDIALOG 810/2

and vrnetDIALOG 840/2 and 860/2

.