Start-up 7

0020224355_00 HOME Installation and maintenance instructions

19

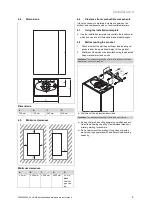

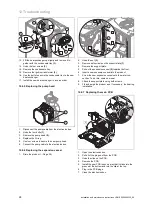

7.9

Checking and adjusting the gas settings

Only a qualified competent person is authorised to imple-

ment the settings on the gas valve.

Each destroyed seal must be restored.

The CO2 adjusting screw must be sealed.

Never modify the factory setting of the gas pressure regu-

lator of the gas valve.

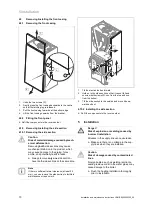

7.9.1

Checking the gas connection pressure (gas

flow pressure)

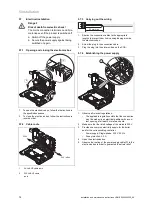

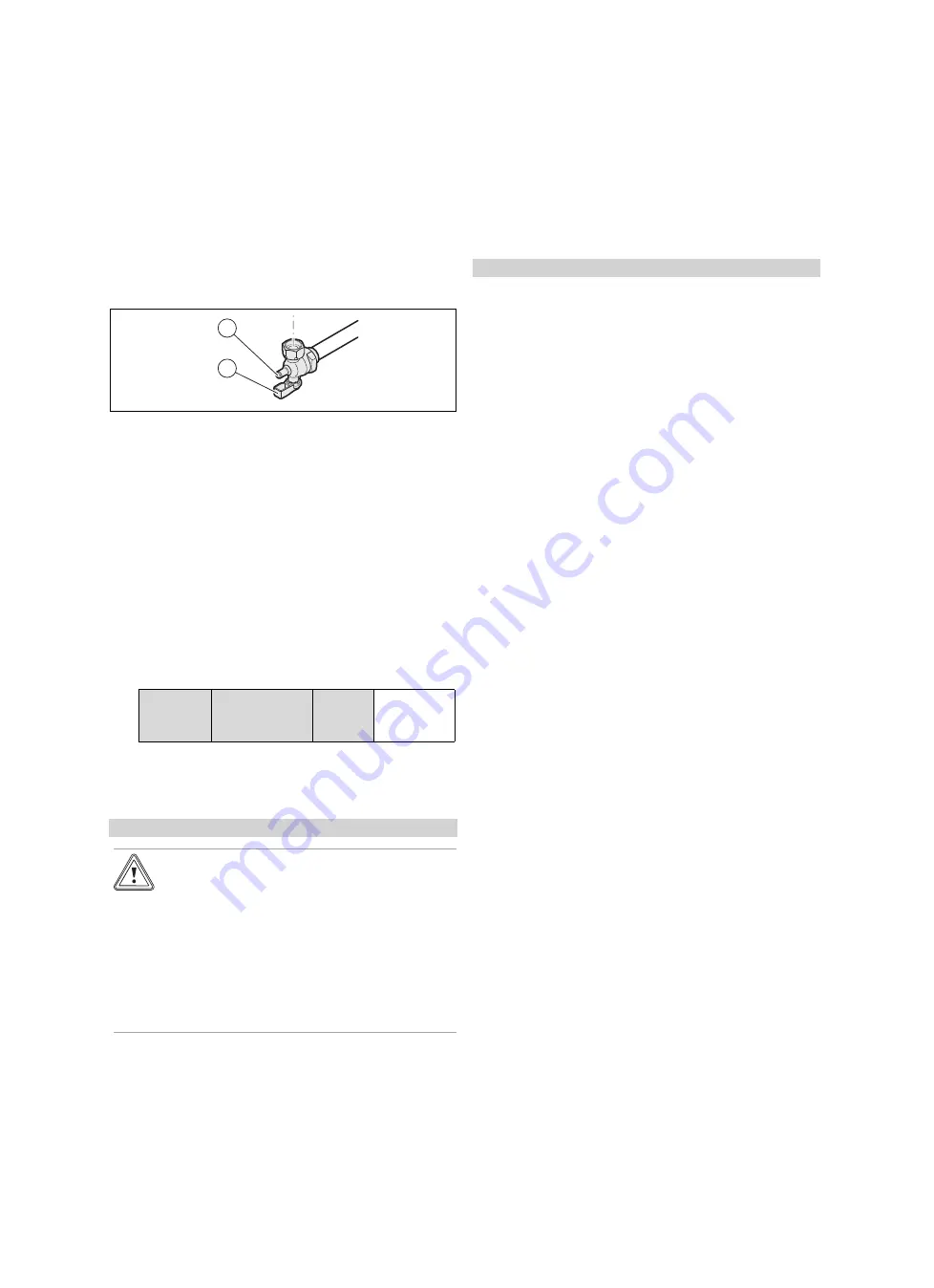

1

2

1.

Ensure that the gas inlet working pressure can be

obtained with all other gas appliances in the property

working.

2.

Close the gas isolator cock.

3.

Undo the sealing screw on the measuring nipple

(2)

.

4.

Connect a pressure gauge to the measuring nipple

(2)

.

5.

Open the gas isolator cock.

6.

Start up the product with check programme P.01.

7.

In addition, ensure that maximum heat can be dissip-

ated into the heating system by turning up the room

thermostat.

8.

With the boiler operating at full load check that the gas

inlet working pressure at the reference test point

(2)

complies with the requirements.

Permissible connection pressure

Great Bri-

tain

Natural gas

G20

1.7 … 2 kPa

(17.0

… 20 mbar)

9.

Should the pressure recorded at the reference test point

in the boiler be lower than indicated check if there is

any blockage in the pipework or if the pipework is un-

dersized.

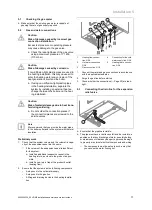

Conditions

: Gas flow pressure

not

in the permissible range

Caution.

Risk of material damage and operating

faults caused by incorrect gas connec-

tion pressure.

If the gas connection pressure lies outside

the permissible range, this can cause oper-

ating faults in and damage to the product.

▶

Do not make any adjustments to the

product.

▶

Do not start up the product.

▶

If you cannot correct the failure, notify the gas supply

company and proceed as follows:

▶

End check programme P.01.

▶

Allow the boiler to cool down by allowing pump overrun

to operate for a minimum of two minutes.

▶

Close the gas isolator cock.

▶

Remove the pressure gauge and retighten the sealing

screw

(2)

for the measuring nipple.

▶

Open the gas isolator cock

(1)

.

▶

Check the measuring nipple for gas tightness.

▶

Close the gas isolator cock

(1)

.

▶

Fit the front panel. (

→

Page 10)

▶

Disconnect the product from the power mains.

▶

You must not start up the boiler.

Conditions

: Gas flow pressure

in the

permissible range

▶

End the check programme

P.01

.

▶

Allow the boiler to cool down allowing pump overrun to

operate for a minimum of two minutes.

▶

Close the gas isolator cock

(1)

.

▶

Remove the pressure gauge and retighten the sealing

screw

(2)

for the measuring nipple.

▶

Open the gas isolator cock

(1)

.

▶

Check the measuring nipple for gas tightness.

▶

Fit the front panel. (

→

Page 10)

▶

Reset boiler controls for normal operation.

▶

Record the appliance gas inlet working pressure (kPa

resp. mbar) in the Benchmark gas boiler commissioning

checklist.

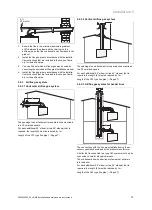

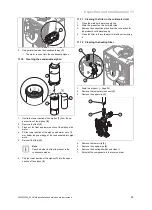

7.9.2

Checking the leak-tightness of the flue gas

system and for flue gas recirculation

1.

Check that the flue gas system is intact, in accordance

with British Gas TB 200.

2.

If the flue gas installation is longer than 2 m, a flue gas

recirculation test is strongly recommended. This test

must be carried out in accordance with the instructions

below.

3.

Use the air analysis point

(1)

to check for flue gas recir-

culation.

4.

Use the flue gas measuring instrument.

5.

If you discover CO or CO2 in the fresh air, search for a

leak in the flue gas system or for the flue gas recircula-

tion.

6.

Eliminate the damage.

7.

Repeat the above-mentioned test to determine if the

fresh air contains CO or CO2.

8.

If you cannot eliminate the damage, you must not start

up the boiler.

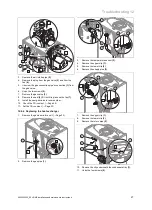

7.9.3

Thoroughly flushing the heating installation

("hot")

1.

Operate the appliance until the boiler and the heating

system are up to temperature.

2.

Check the heating system for leaks.

3.

Connect a hose to the drain valve located at the lowest

position of the heating system.

4.

Shut off the boiler, open the drain valve and all purge

valves on the radiators and allow the water to flow out

of the heating system and the boiler quickly and fully.

5.

Close the drain valve.

6.

Fill and purge the heating installation. (

→

Page 18)

7.

Re-fill the system until the system design pressure of

0,1 MPa (1,0 bar) is attained.

Summary of Contents for home combi

Page 51: ......