8 Adapting the unit to the heating installation

20

Installation and maintenance instructions HOME 0020224355_00

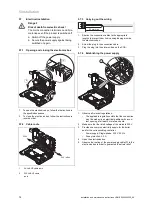

Note

The actual reading on the digital pressure

gauge should ideally be 0,05 MPa (0,5 bar)

plus an additional pressure corresponding

to the highest point of the system above the

base of the boiler

–

10 m head equals an ad-

ditional 1 bar reading on the pressure gauge.

The minimum pressure should not be less

than 0,1 MPa (1 bar) in any installation. If

the system is to be treated with an inhibitor it

should be applied at this stage in accordance

with the manufacturer’s instructions. Further

information can be obtained from Sentinel,

Betz Dearborn Ltd., Tel: 0151 420 9595, or

Fernox, Alpha

–

Fry technologies. Tel: 0870

8700362.

8.

Fit the front panel. (

→

Page 10)

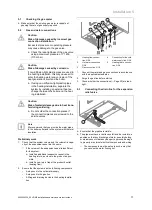

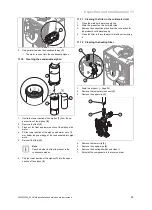

7.9.4

Checking the CO

₂

content

1.

Start up the product with the check programme

(P.01)

and set the value.

–

Setting value for the programme P.01: 100

Check programmes

–

Overview (

→

Page 30)

2.

Wait until the value that is read is stable.

–

Waiting period for reading a stable value: 5 min

1

3.

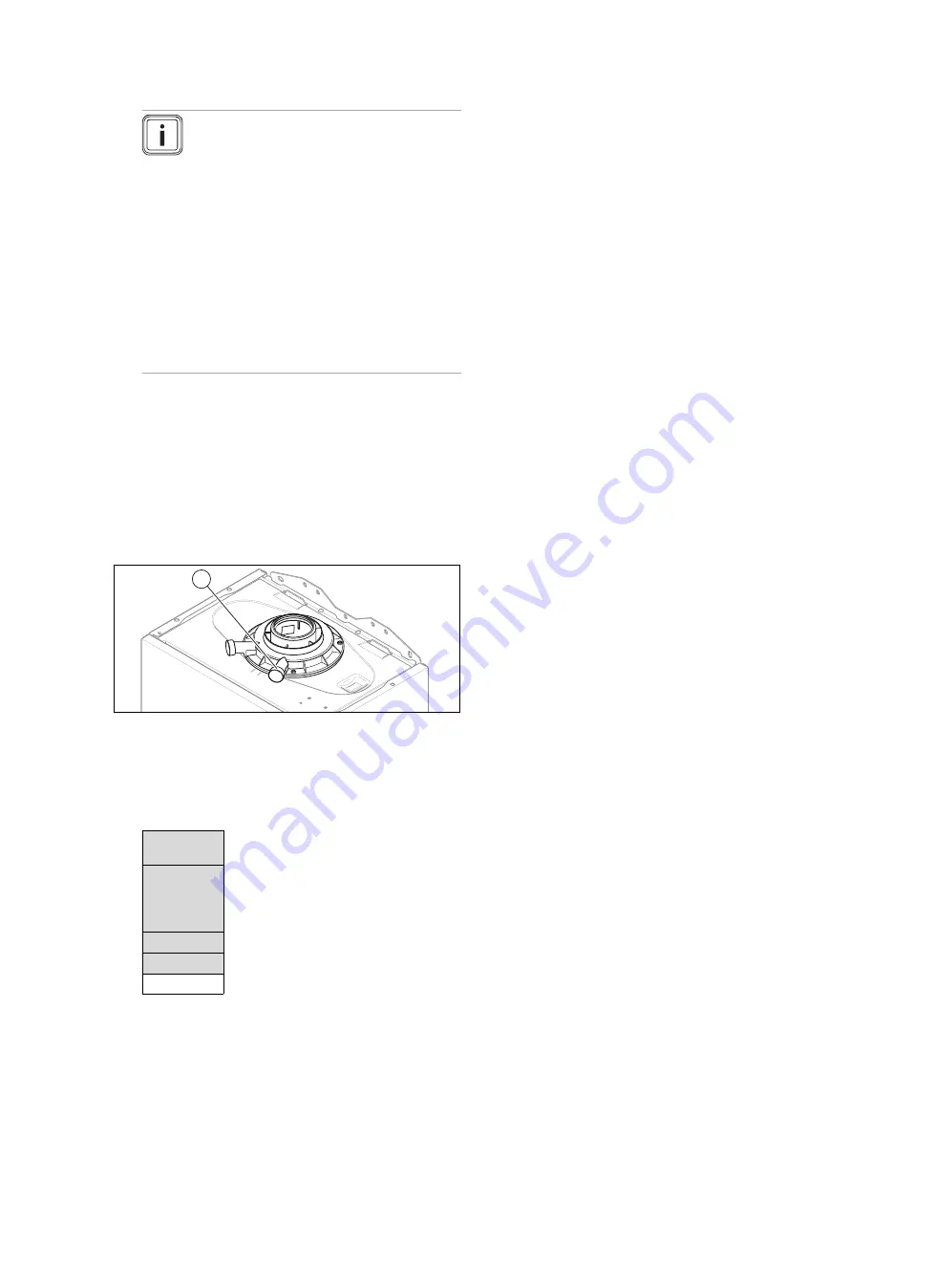

Unscrew the cover from the flue gas analysis point

(1)

.

4.

Measure the CO

₂

content at the flue gas analysis point

(1)

.

5.

Compare the measured value with the corresponding

value in the table.

Checking the CO

₂

content

Great Bri-

tain

Removed

front cas-

ing/installed

front casing

Natural gas

G20

9.2

±

1 %

◁

The value is OK.

▽

The value is not OK; you cannot start up the

product.

▶

Inform Customer Service.

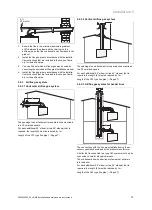

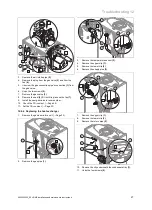

7.10

Checking function and leak-tightness

Before you hand the product over to the operator:

▶

Check the gas line, the flue gas installation, the heating

installation and the hot water pipes for leaks.

▶

Check that the air/flue pipe and condensate drain pipe-

work have been installed correctly.

▶

Check that the front casing has been installed correctly.

7.10.1 Checking the heating mode

1.

Activate the heating mode on the user interface.

2.

Turn all thermostatic radiator valves on the radiators

until they are fully open.

3.

Allow the product to operate for at least 15 minutes.

4.

Purge the heating installation.

5.

Activate the display for the current operating status.

(

→

Page 16)

Status codes

–

Overview (

→

Page 34)

◁

If the product is working correctly, the display shows

S.04.

7.10.2 Checking the hot water generation

1.

Activate the hot water handling mode on the user inter-

face.

2.

Open a hot water valve completely.

3.

Activate the display for the current operating status.

(

→

Page 16)

Status codes

–

Overview (

→

Page 34)

◁

If the product is working correctly, the display shows

S.14.

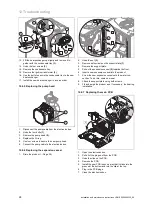

8

Adapting the unit to the heating

installation

You can reset/change the system parameters (section "Us-

ing diagnostics codes").

Overview of diagnostics codes (

→

Page 30)

8.1

Burner anti-cycling time

To prevent frequent switching on and off of the burner and

thus prevent energy losses, an electronic restart lockout

is activated for a specific period each time the burner is

switched off. The burner anti-cycling time is only active for

the heating mode. Hot water handling mode during a burner

anti-cycling time does not affect the time function element.

8.1.1

Setting the maximum burner anti-cycling

time

1.

Set the diagnostics code. (

→

Page 15)

Overview of diagnostics codes (

→

Page 30)

2.

If required, adjust the maximum burner anti-cycling time

using the diagnostics code

d.02

.

Summary of Contents for home combi

Page 51: ......