Inspection, maintenance and repair 10

0020188110_03 recoVAIR Installation and maintenance instructions

17

6.

Unscrew the condensate siphon from the product.

7.

If they are dirty, clean the condensate discharge pipe,

the condensate tray and the condensate siphon.

8.

Secure the condensate siphon to the product.

(

→

Page 10)

9.

Place the heat exchanger in the guide rails and slide

the heat exchanger back into the product.

10. Place the cover on the heat exchanger with new seals

and screw it down tightly.

11. Close the product. (

→

Page 11)

10.3.4 Cleaning the frost protection element

1.

Open the product. (

→

Page 11)

Caution.

Risk of material damage caused by incor-

rect cleaning.

Water and other liquids may damage the frost

protection element.

▶

Use only a vacuum cleaner to clean the

frost protection element.

2.

Clean the frost protection element.

–

Vacuum cleaner

3.

Close the product. (

→

Page 11)

10.3.5 Maintaining the filters

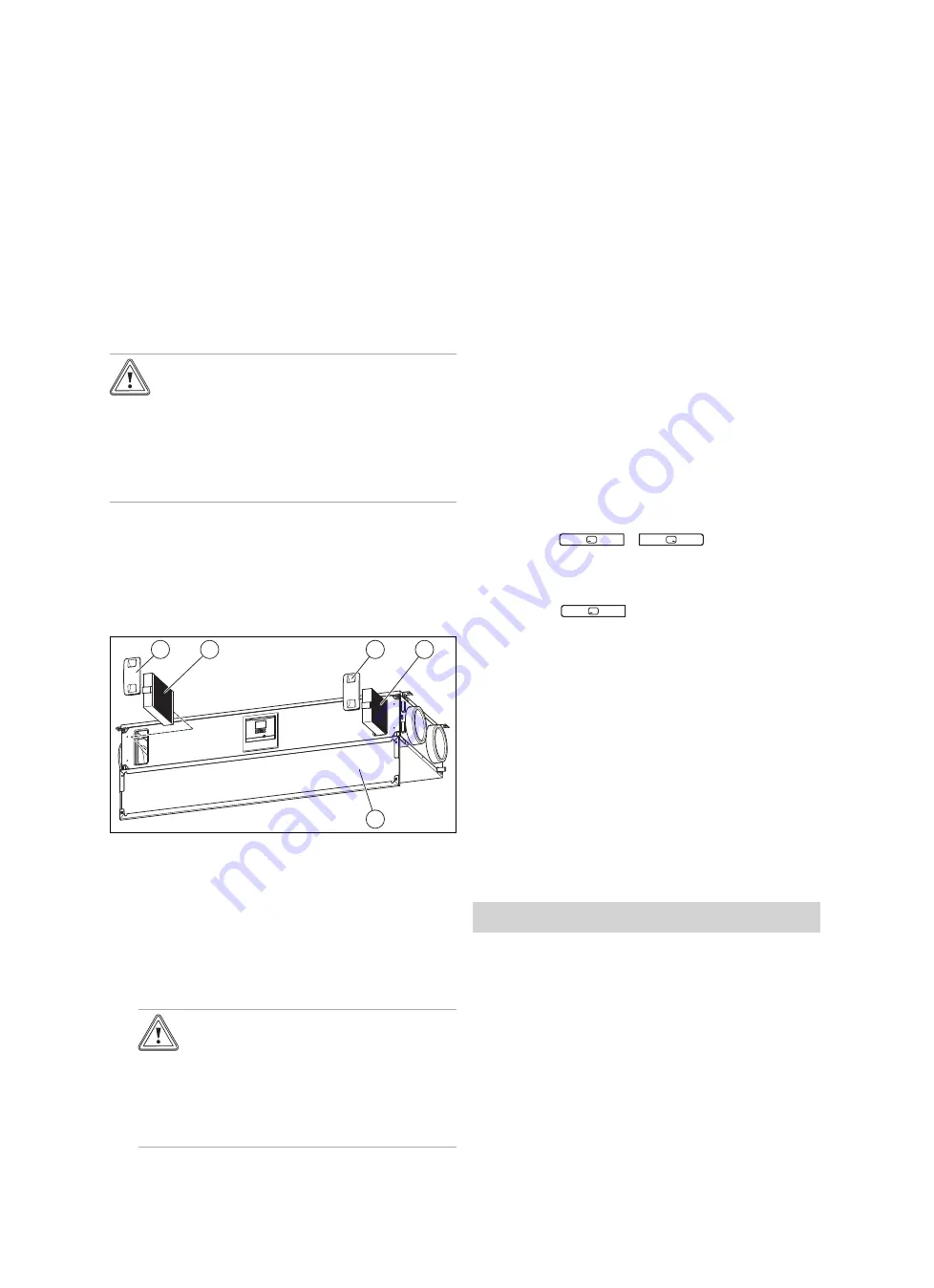

Removing the filters

1

2

1

3

2

1.

Open the front flap

(3)

.

2.

Pull out both of the filter plugs

(1)

.

3.

Pull the outdoor- and exhaust-air filter

(2)

out of the

product.

4.

Check the filters for dirt.

–

Recommended check: Every three months

1 / 2

Degree of contamination: Filter is lightly soiled

Caution.

Risk of material damage caused by

incorrect cleaning of the filter.

Water and other liquids may damage the

filters and the product.

▶

Only clean the filters with a vacuum

cleaner.

▶

Clean the filters.

–

Vacuum cleaner at a low setting

2 / 2

Degree of contamination: Filter is heavily soiled

Operating days:

≥

182 d

Replacement interval reached: At least twice annually

▶

Replace the filters.

–

Exhaust-air filter class: G4 (in accordance

with EN 779)/ISO Coarse (in accordance with

ISO 16890)

–

Outdoor-air filter class: F7 or F9 (in ac-

cordance with EN 779)/ISO ePM2.5 70%

or ISO ePM1,0 85% (in accordance with

ISO 16890)

–

Exhaust air valve filter

Installing the filters

5.

Install the filters in the product and ensure that they are

correctly aligned as you do so.

–

Labelling on the filters

–

Sticker on the inside of the front flap

6.

Place the filter plugs on the filters.

Resetting the filter days

7.

Switch on the product. (

→

Page 13)

8.

Press the

+

buttons simultan-

eously to access the menu.

9.

Navigate to the

Resets

menu

→

Res. days until fil. ch.

.

10. Reset the filter days.

11. Press the

button to exit the menu.

12. Close the front flap.

10.3.6 Increase/establish system efficiency

1.

Clean the supply and exhaust air valves and their cor-

responding filters. (

→

Page 16)

2.

Check the exposed piping for leaks.

3.

Check whether any obstructions are impeding the air

flows.

4.

If required, re-adjust the supply-air and exhaust-air

valves.

5.

Clean the outside air's intake tract and the exit air's

outlet openings.

6.

Carry out maintenance on the product filter.

(

→

Page 17)

7.

Remove the front flap if this has not yet been done.

Conditions

: The maintenance message

M.802

was previously shown in

the display.

▶

Switch the product on if this has not already been done.

(

→

Page 13)

◁

The system efficiency is checked automatically.

1 / 2

Maintenance message

M.802

is no longer shown in the

display.

No other measures are required.

2 / 2

Maintenance message

M.802

is still being shown in the

display.

▶

Measure/initialise the system. (

→

Page 15)