Appendix

22

Installation and maintenance instructions recoVAIR 0020188110_03

C

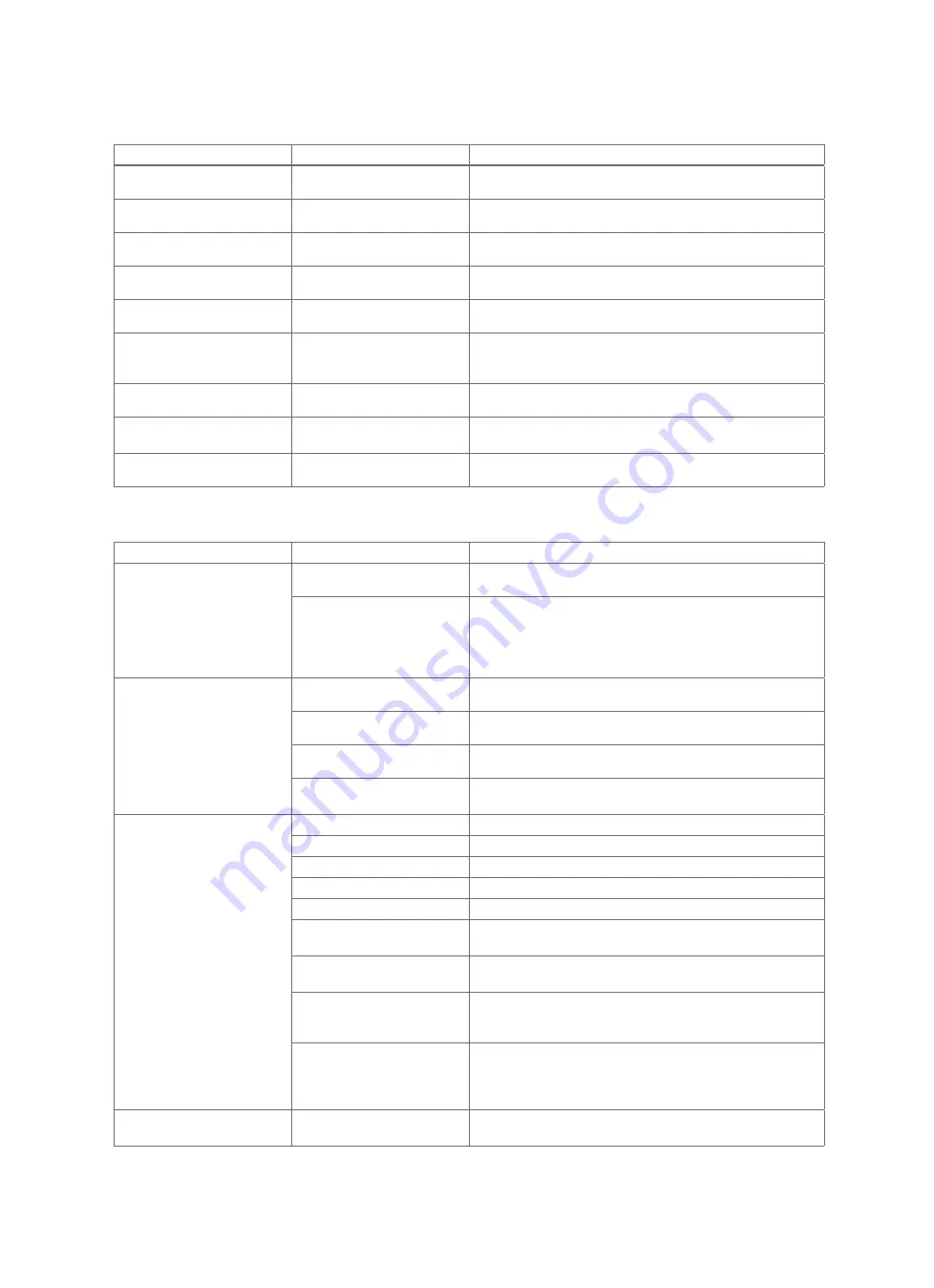

Limp home mode messages

–

Overview

Message

Possible cause

Measure

Lhm.801 Failure: Exh. air

temp. sensor

Exhaust-air temperature sensor

does not work/is defective

▶

Check that the exhaust-air temperature sensor works correctly.

Lhm.802 Failure: Exit air

sensor

Exit-air temperature sensor

does not work/is defective

▶

Check that the exit-air temperature sensor works correctly.

Lhm.803 Failure: Supply

temp. sensor

Supply-air temperature sensor

does not work/is defective

▶

Check that the supply-air temperature sensor works correctly.

Lhm.804 Failure: Outside air

temp. sensor

Outside temperature sensor

does not work/is defective

▶

Check that the outside temperature sensor works correctly.

Lhm.805 Failure: Exhaust air

humidity sensor

Exhaust-air humidity sensor

does not work/is defective

▶

Check that the exhaust-air humidity sensor works correctly.

Lhm.806 Supply air temp. too

low

Frost protection active

▶

Wait until the supply-air temperature increases again. The

product then starts normal operation.

Supply air temp.: > 10

℃

Lhm.807 Failure/fault: Air

quality sensor

Air quality sensor does not

work/is defective

▶

Check the air quality sensors.

Lhm.810 No connection to

step switch

4-step switch does not work/is

defective

1.

Activate the 4-step switch in the installer level.

2.

Check that the 4-step switch works correctly.

Lhm.817 Failure: Frost prot.

element

The frost protection element is

defective

▶

Replace the frost protection element.

D

Troubleshooting

Symptom

Possible cause

Measure

Product not operating

The mains voltage has been

interrupted/power cut

▶

Wait until the mains voltage has been re-established and the

product automatically switches on (all settings are retained).

Frost protection active (mains

voltage present)

1.

Check whether

S.815

is displayed in the

Live Monitor

.

2.

Wait until the outside temperature increases (the product

automatically switches on no later than 60 minutes after the

temperature increases.).

–

Outside temperature: >

−

3

℃

Product with increased noise

level

Missing/incorrect silencer in the

supply-air exhaust-air pipes

▶

Install silencers in accordance with the system planning.

System components (e.g. heat

exchanger, fan) are defective

▶

Replace defective system components.

System components (e.g. heat

exchanger, fan) are dirty

▶

Clean dirty system components.

Fan runs at maximum rotational

speed

1.

Check whether the pressure hoses are bent.

2.

Reduce the air volume flow at the lowest ventilator speed.

No or insufficient exhaust air or

supply air

Filter dirty

▶

Clean the filters.

Exhaust-air line blocked

▶

Clean the exhaust-air line.

Supply-air line blocked

▶

Clean the supply-air line.

Fan defective

▶

Replace the fan(s).

Air flow too low

▶

Install an intake grille that has increased air flow.

Supply-air valve is closed too

far

1.

Open the supply-air valve.

2.

Adjust the system.

Exhaust-air valve is closed too

far

1.

Open the exhaust-air valve.

2.

Adjust the system.

Supply-air temperature too low

▶

Wait until the supply-air temperature increases again. The

product then starts normal operation.

Supply air temp.: > 10

℃

Outside temperature too low

1.

Check whether

S.812

is displayed in the

Live Monitor

.

2.

Wait until the outside temperature increases again. The

product then starts normal operation.

–

Outside temperature: >

−

3

℃

Bypass summer mode does not

work

Bypass function not active

1.

Activate the bypass function.

2.

Set the planned operating days for summer mode.