Appendix

0020188110_03 recoVAIR Installation and maintenance instructions

23

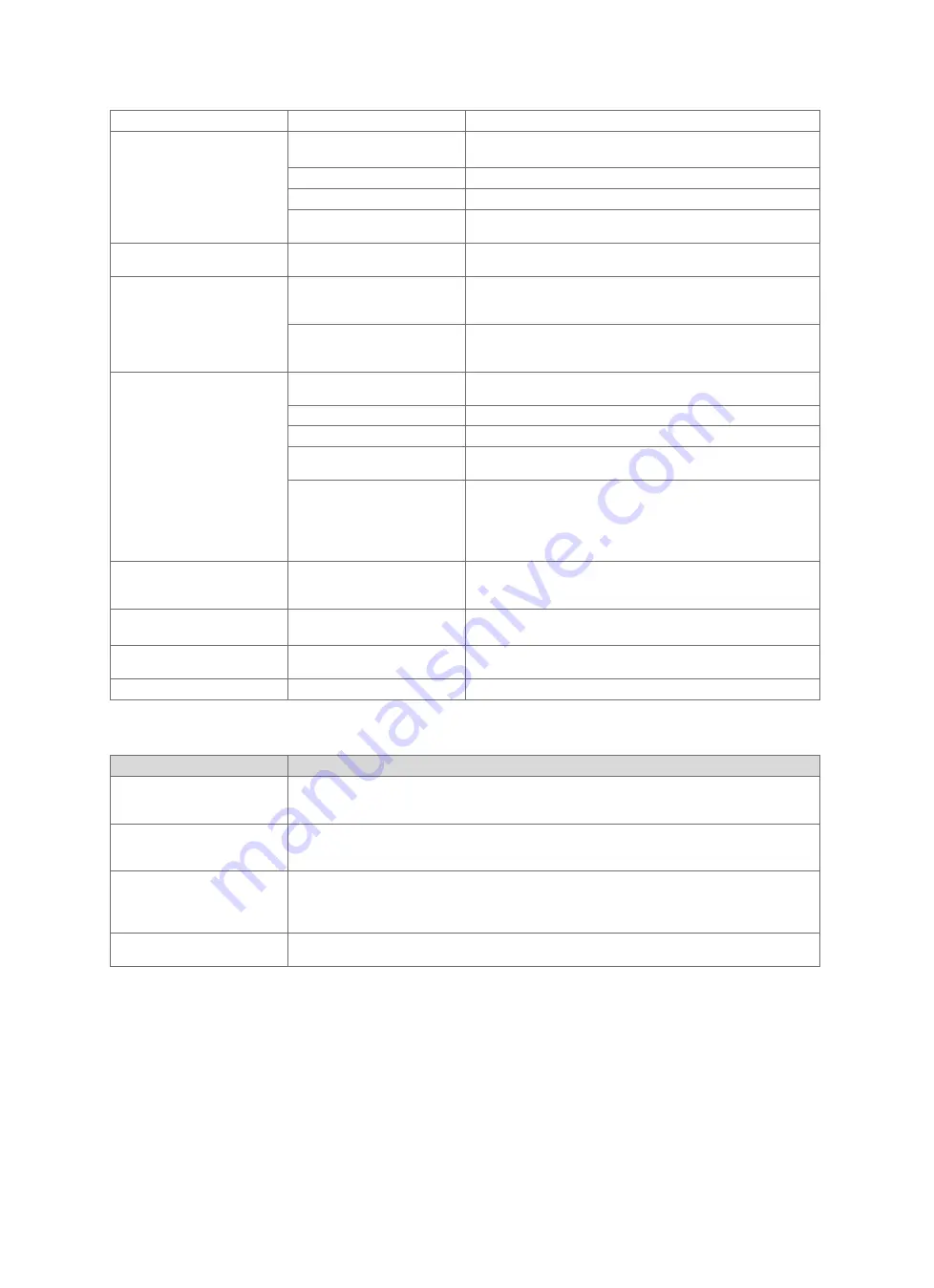

Symptom

Possible cause

Measure

Bypass summer mode does not

work

The bypass motor is connected

incorrectly

1.

Check the plug connection to the bypass motor.

2.

Check the temperature sensor.

Bypass motor is defective

▶

Replace the bypass motor.

Incorrect flap position

▶

Check the flap position.

The temperature sensor is posi-

tioned incorrectly

▶

Check the positioning of the temperature sensor.

Noises in the condensate drain

pipework

Condensate siphon connected

incorrectly

▶

Connect the condensate siphon correctly.

Water drips out of the product

Exhaust-air lines not insulated

to ensure that they are vapour-

diffusion-tight

▶

Insulate the exhaust-air lines so that they are vapour-diffusion-

tight.

Supply-air lines not insulated

to ensure that they are vapour-

diffusion-tight

▶

Insulate the supply-air lines so that they are vapour-diffusion-

tight.

The supply air is too cold

Supply-air and exhaust-air flows

are not balanced

▶

Adjust the product.

Incorrect flap position

▶

Check the flap position.

Bypass motor is defective

▶

Replace the bypass motor.

System components (e.g. heat

exchanger, fan) are dirty

▶

Clean dirty system components.

Frost protection active (mains

voltage present)

1.

Check whether

S.815

is displayed in the

Live Monitor

.

2.

Wait until the outside temperature increases (the product

automatically switches on no later than 60 minutes after the

temperature increases.).

–

Outside temperature: >

−

3

℃

Bad and/or unpleasant odours

present

Openings for the supply-air and

exhaust-air lines are too close

to each other

▶

Increase the distances between the openings for the supply-air

and exhaust-air lines.

Noise transmission between the

rooms

No T supersonic damper in-

stalled

1.

Install T supersonic dampers.

2.

Adjust the product.

Planned air volume flow not

available after installation

Installation is not vapour-diffu-

sion-tight

▶

Check that all of the connections are leak-tight.

Noises after replacing the fan

Fan installed incorrectly

▶

Check the fan's installation location.

E

Check programmes

–

Overview

Prüfprogramme

Meaning

P.01 Bypass test

The bypass flap is actuated and moved to the closed and open position. In the event of a negative

test result,

Test not OK

is shown in the display. Then check that the bypass is connected correctly

and works correctly. If required, replace/clean components.

P.02 Test Frost prot. element

A defined volume flow is created by the ventilation unit and the frost protection element is switched

on. In the event of a negative test result,

Test not OK

is shown in the display. Check that the frost

protection element is connected correctly and works correctly. If required, replace components.

P.03 Initialisation measure

The ventilation unit runs through four ventilation levels, one after the other. The rotational speeds of

the ventilation levels are used as characteristic lines for monitoring the system efficiency. The check

programme must always be run through before the system efficiency function can be activated in the

configuration menu.

P.04 System efficiency test

The prerequisite is that check programme

P.03

has been executed once previously. To check the

system efficiency, four volume flows are created by the ventilation unit.