Installation Manual recoVAIR/3 0020062918_03

34

6.4

Cleaning or Replacing the Bypass Filter

e

Danger!

Risk of fatal electric shock from touching live

connections. Pull the mains plug before starting

to work on the device.

The domestic ventilation unit may be equipped with a

bypass, if required.

Demounting, control and cleaning of the bypass-filter

are described in detail in the operating manual in

section 6.2.

6.5

Test Operation and Restart

After the inspection/maintenance work check the cor-

rect functioning of the unit:

• Check that the unit casing is correctly closed.

• Insert the mains plug into the plug socket and start

the unit.

• Check the correct function of the unit.

• Check the correct function of the remote control.

6.6

Spare Parts and Accessories

In order to continuously ensure the correct function of

the Vaillant unit and not to change series-production

status it is absolutely mandatory only to use genuine

Vaillant spare parts for the maintenance and mainte-

nance work.

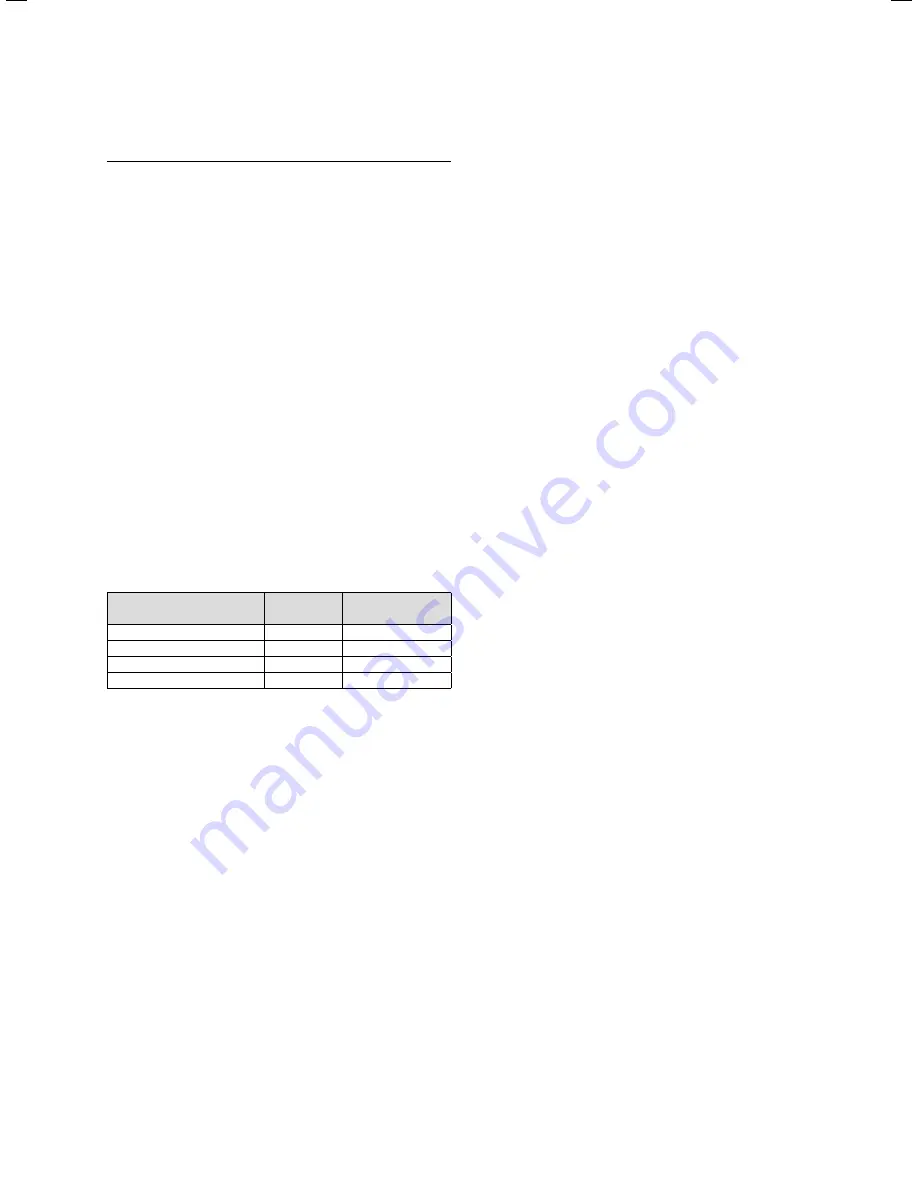

Description

Filter class

Ordering number

Filterset recoVAIR

G3

0020023930

Filter recoVAIR Bypass

G3

0020023931

Feinfilterset recoVAIR

F6

0020026061

Feinfilter recoVAIR Bypass

F6

0020026118

Table 6.1 Accessories

6 Inspection and maintenance

Summary of Contents for recoVAIR VAR 275/3

Page 2: ......

Page 14: ......

Page 43: ......

Page 44: ...0020062918_03 GB 062009 Subject to alterations ...