38

7.9 Replacement of CH

expansion vessel

In the unlikely event of a failure of the

CH expansion vessel follow procedure

7.9.1 or 7.9.2 depending upon the

installation circumstances.

7.9.1. Boiler installed with air/flue

duct to left/right hand side, or

vertical flue installation (where

300mm vertical clearance exists

above the boiler).

•

Remove front casing as in section

7.1.3

•

Turn off the boiler as in section

7.1.1.

•

Release CH water pressure and

drain boiler as in section 7.1.2.

•

Remove combustion chamber cover

as in section 7.1.5

•

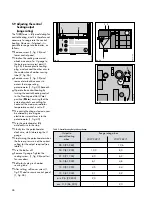

Remove 2 screws (2, fig 63).

•

Remove screw (1, fig. 56) to

release air pressure switch.

•

Slide expansion vessel upwards

and out of boiler casing.

•

Replace in reverse order.

•

Refill and repressurise the boiler

(see section 5.4).

2

4

3

1

1

2

fig. 64

GW 620/1

7.9.2 Boiler installed with air flue duct

to the rear, or vertical flue

installation (where less than

300mm vertical clearance exists

above the boiler)

EITHER

Remove the boiler from the wall as

follows:

•

Remove front casing as in section

7.1.3

•

Turn off the boiler as in section

7.1.1.

•

Release CH water pressure and

drain boiler as in section 7.1.2.

•

Lower front control panel as in

section 7.1.6

•

Disconnect external wiring from

boiler wiring terminal box.

•

Disconnect flow and return

connections at compression

connection above boiler CH service

valves (1, fig. 64).and remove two

screws securing retaining lug to

appliance chassis

(2, fig. 64)

•

Disconnect gas connection at

compression joint on top of gas

service valve (3, fig. 64).

•

Disconnect domestic hot and cold

water connections (4, fig. 64)

•

Disconnect the flue from the top of

boiler as described in section 4.6.

•

Remove boiler from wall.

•

Remove screw (1, fig. 56) to

release air pressure switch.

•

Remove two screws (2, fig. 63) and

slide expansion vessel upwards

and out of boiler casing.

•

Reassemble in reverse order.

•

Re-mount the boiler (see section 4.5

and 4.6).

•

Re-commission the boiler (see

section 5).

OR

A suitable replacement expansion

vessel can be fitted externally to the

boiler as described in Section 3.7.5

(if possible on the central heating

return in an accessible position). In

these circumstances, the replacement

expansion vessel must be correctly

sized ignoring the original expansion

vessel which can be left in position on

the boiler.

2

1

3

fig. 63

GW 639/1