Handing the product over to the end user 7

0020221303_02 uniSTOR HP Installation and maintenance instructions

15

–

Setting the thermostats: 60

℃

6.

Start up the heat generator.

7.

Drain the heating circuit as soon as the operating

temperature has been reached in order to remove any

residue from the heating installation.

8.

Fill and purge the primary circuit. Consult the installa-

tion instructions for the heat generator.

7

Handing the product over to the end

user

▶

Once the installation is complete, show the user the loca-

tion and function of the safety devices.

▶

Inform the end user how to handle the product.

▶

In particular, draw attention to the safety warnings which

the end user must follow.

▶

Inform the end user of the necessity to have the product

maintained according to the specified intervals.

8

Troubleshooting

8.1

Detecting and eliminating faults

▶

If problems occur whilst operating the product, check

certain points with the aid of the table in the appendix.

Detecting and eliminating faults (

8.2

Procuring spare parts

The original components of the product were also certified

by the manufacturer as part of the declaration of conformity.

If you use other, non-certified or unauthorised parts during

maintenance or repair work, this may void the conformity of

the product and it will therefore no longer comply with the

applicable standards.

We strongly recommend that you use original spare parts

from the manufacturer as this guarantees fault-free and safe

operation of the product. To receive information about the

available original spare parts, contact the contact address

provided on the back page of these instructions.

▶

If you require spare parts for maintenance or repair

work, use only the spare parts that are permitted for the

product.

9

Inspection and maintenance

9.1

Observing inspection and maintenance

intervals

Adhere to the minimum inspection and maintenance inter-

vals. The inspection may require maintenance to be carried

out earlier, depending on the results.

Inspection and maintenance work

–

Overview (

The immersion heater can be removed in order to inspect

the inside of the cylinder.

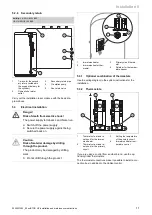

9.2

Draining the product

1.

Close the cold water draw-off valve.

2.

Secure a hose to the drain valve.

3.

Position the hose at a suitable drain.

4.

Open the highest hot water tap in the installation.

5.

Open the drain valve and drain the product completely.

6.

Close the hot water tap and the drain valve.

7.

Remove the hose.

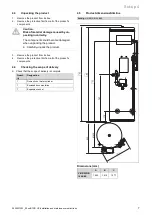

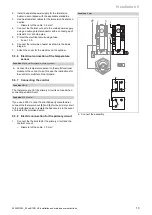

9.3

Checking the safety group's expansion

relief valve and the cylinder's expansion

relief valve

1.

Open all expansion relief valves by turning the plug.

2.

Check whether the water is flowing into the tundish.

3.

Check that the expansion relief valves are in the correct

position and then check the pressure.

4.

Check and, if required, clean the pressure reducer.

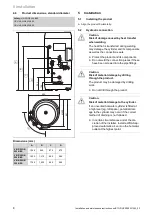

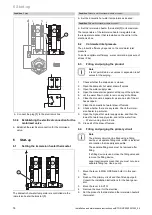

9.4

Checking the pre-charge pressure of the

expansion vessel

1.

Drain the product. (

2.

Measure the pre-charge pressure of the expansion ves-

sel at the vessel valve.

Condition

: Pressure <0.3 MPa (0.3 bar)

▶

Top up the expansion vessel in accordance with the

static height of the heating installation, ideally with ni-

trogen, otherwise with air.

3.

If water escapes from the valve of the expansion ves-

sel, you must replace the expansion vessel.

4.

Fill and purge the product. (

10 Decommissioning the product

▶

Switch off the heat generator.

▶

Unplug the domestic hot water cylinder's mains plug.

▶

Close the cold-water stopcock.

▶

Drain the product. (

▶

Remove the hydraulic connections and the temperature

sensor.

▶

Remove the cables for the temperature sensor from the

heat generator, control or multi-functional module.

11 Customer service

To ensure regular servicing, it is strongly recommended

that arrangements are made for a Maintenance Agreement.

Please contact Vaillant Service Solutions for further details:

Telephone: 0330

100

3461

Summary of Contents for uniSTOR HP VIH RW GB BES Series

Page 23: ......