0020152779_05 - 10/14 - Vaillant

13

EN

REPAIR WORK

5.2

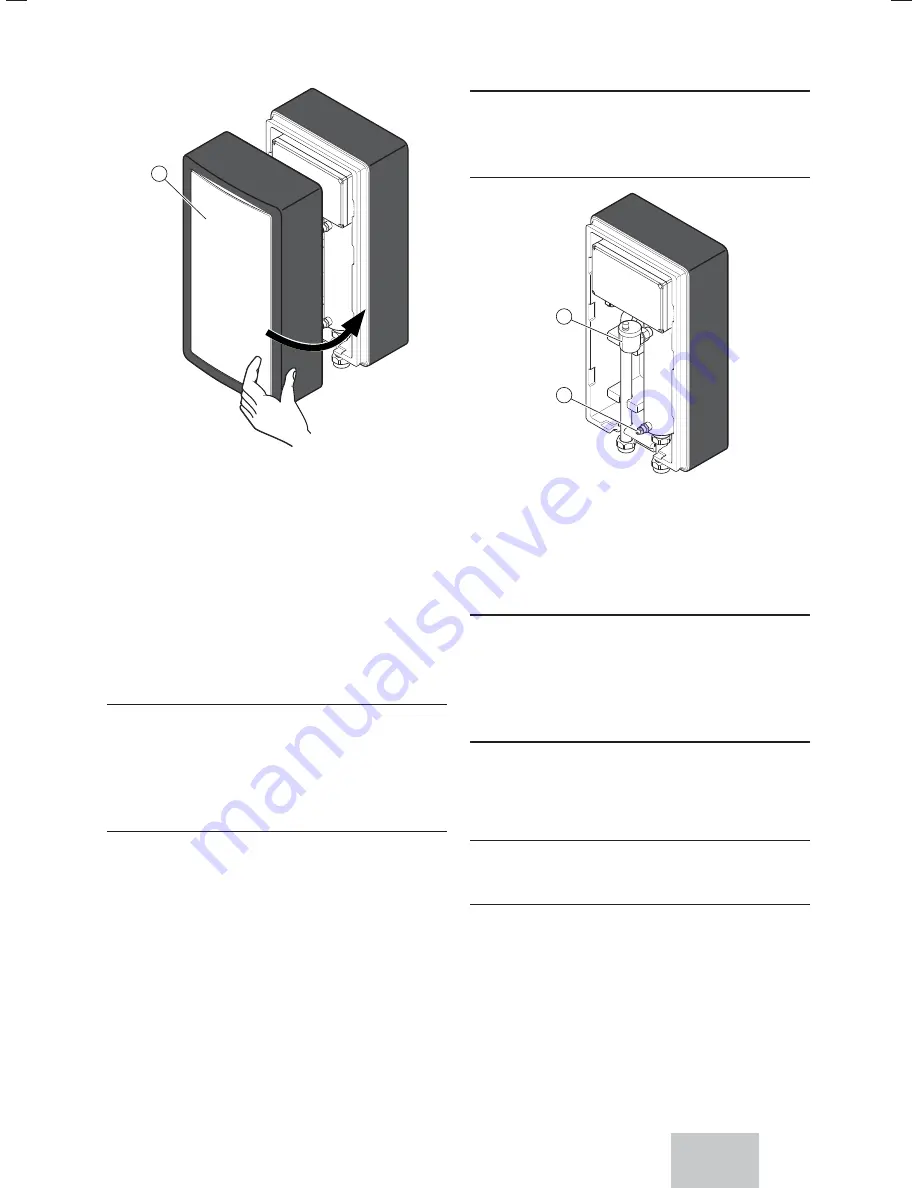

Installing the casing

1

1 Front

casing

►

Put the front casing back on

5.3

Handing over the product to the user

After completing the installation:

►

Answer any questions the user may have.

►

Draw special attention to the safety instructions which the

user must follow.

6 Repair

work

e

Danger!

Risk of death from electric shock!

Touching live connections may

cause serious personal injury.

►

Switch off the electrical supply

during the maintenance operation.

6.1 Spare

parts

►

In case you need spare parts during maintenance or

repair, exclusively use genuine Vaillant spare parts.

The genuine component parts of the product have been

certi

fi

ed together with the product in the course of the CE

conformity check. If you do not use certi

fi

ed genuine Vaillant

spare parts during maintenance or repair, the CE conformity

of the product will expire. That is why we imperatively

recommend to install genuine Vaillant spare parts.

6.2

Draining the product

b

Caution!

Risk of material damage

►

Avoid all risk of water projection

onto the electrical components.

2

1

1 Air

vent

2 Drainage

plug

►

Open the appliance's drainage plug (2).

►

Open the appliance's air vent (1).

6.3

Resetting the Electrical back-up heater

b

Caution!

Risk of material damage

►

For this measure, an advance

check is required and this must

only be carried out by a

competent person.

In case of an abnormal increase in water temperature, the

heating element's safety thermostat may be triggered (Refer

to the installation manual control box).

It has to be reset manually.

i

Notes

Let the heating element cool before resetting.

Summary of Contents for VWZ MEH 60

Page 15: ......