2

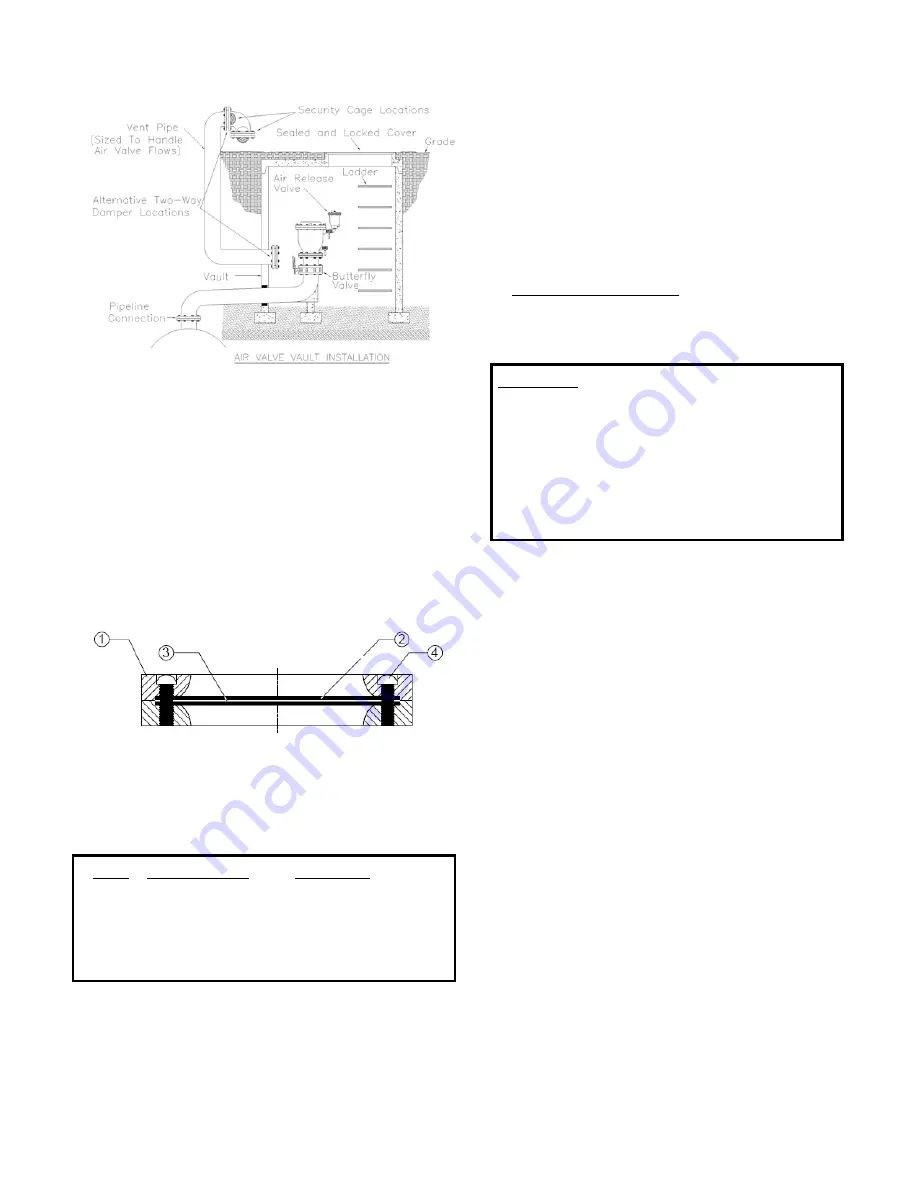

ITEM DESCRIPTION MATERIAL

1 Body

HDPE

2

Rubber Membrane

High Grade Neoprene

3 Damper

Seal

PETG

4

Body Bolt

T316 Stainless Steel

WARNING: If the FrostSafe™ is installed

downstream of an air valve, the

air valve’s isolation valve must be

closed prior to performing

inspection or maintenance of the

FrostSafe

™

. Failure to close the

isolation valve could lead to

bodily injury if the air valve

discharges air during inspection.

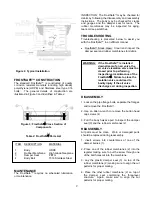

Figure 2. Typical Installation

FROSTSAFE™ CONSTRUCTION

The standard FrostSafe™ is constructed of quality

corrosion resistant materials including high density

polyethylene (HDPE) and Stainless steel type 316

bolts. The general details of construction are

illustrated in Figure 3 and identified in Table 2.

Figure 3: FrostSafe

™

Cross Section of

Components

Table 2: FrostSafe

™

Parts List

MAINTENANCE

The FrostSafe™ requires no scheduled lubrication

or maintenance.

INSPECTION: The FrostSafe

™

may be checked for

debris by following the disassembly and reassembly

instructions. The body may be checked for cracks

and gouges and the damper seal for tears. The

rubber membranes may be inspected for aging,

tears or deep scratches.

TROUBLESHOOTING

Troubleshooting is presented below to assist you

with the FrostSafe™ in an efficient manner.

•

FrostSafe

™

Stuck Open: Clean and inspect the

damper seal and rubber membranes for debris.

DISASSEMBLY

1. Loosen the pipe flange bolts, separate the flanges

and remove the FrostSafe

™

.

2. Use an Allen wrench to remove the button head

cap screws (4).

3. Pull the body halves apart to inspect the damper

seal (3) and the rubber membranes (2).

REASSEMBLY

All parts must be clean. Worn or damaged parts

should be replaced during reassembly.

1. Insert screws into counterbores of one of the

damper bodies (1).

2. Place one of the rubber membranes (2) into the

register making sure to put the screw through one

of the bolt holes cut into the membrane.

3. Lay the plastic damper seal (3) on top of the

rubber membrane (2) making sure to align the cut

patterns for proper mating.

4. Place the other rubber membrane (2) on top of

the damper seal completing the three-layer

structure. Again, make sure to align the cut

patterns for proper mating.