MUS01210202

07/01/2020

MELTON, S.L.U. - POLIGONO INDUSTRIAL AGUSTINOS CALLE G-34,31160 ORCOYEN, NAVARRA

TEL: 00 34 948 321580 Fax: 00 34 948 326584 e-mail: melton@melton.es

56

4. Place the new engine and follow the reverse process explained above.

5. For the screws that attach the motor to the bracket applying a torque of

8.7 N • m.

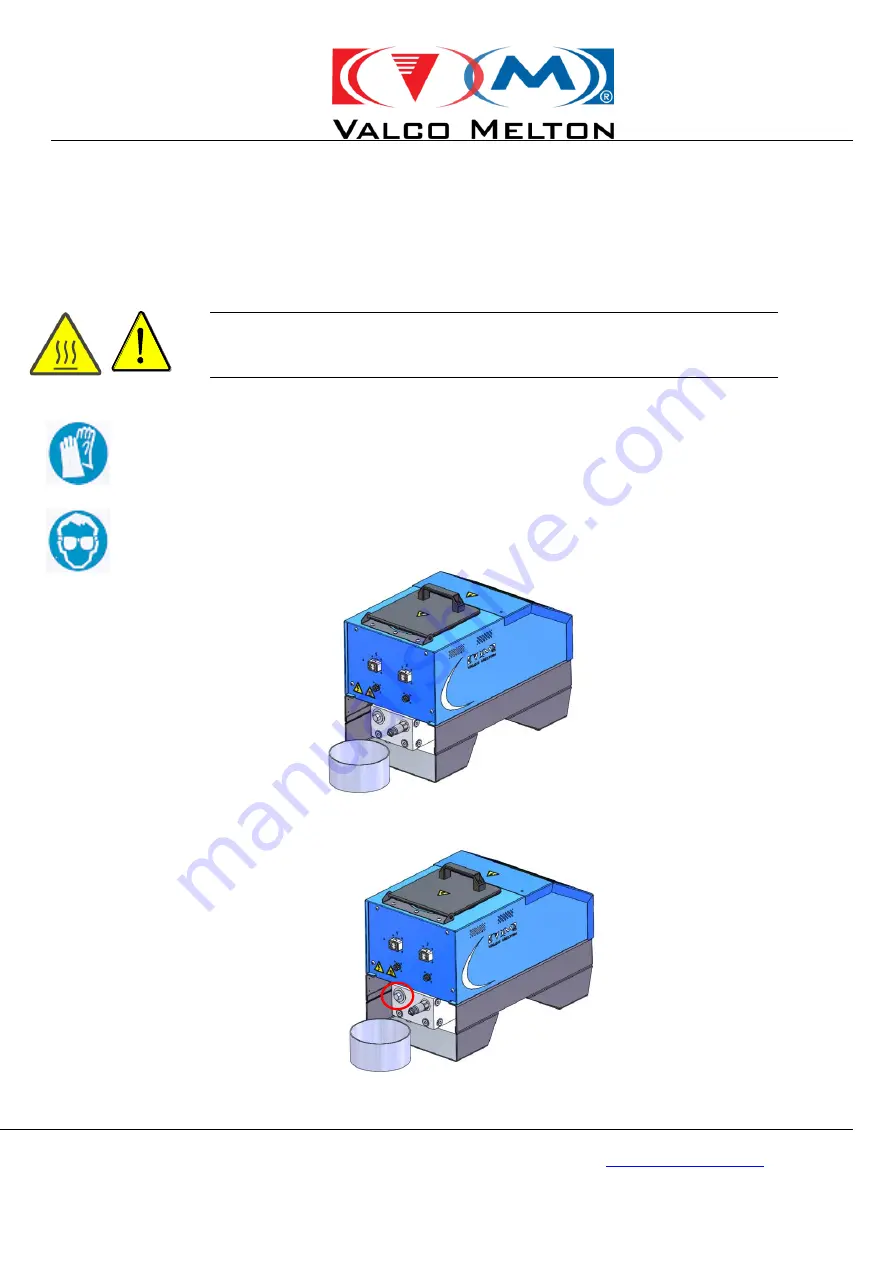

6.3.3. REPLACING THE ADHESIVE FILTER:

Before changing the filter, put on a face shield, gloves and a

long-sleeve shirt to prevent possible burns caused by hot

adhesive splashing.

Keeping a filter or mesh in stock to replace when necessary is recommended. This

replacement is quick and improves the machine performance.

1. Warm the machine to the operating temperature.

2. Stop the pump.

3. Place an appropriate container under the manifold to collect the adhesive.

4.

Activate the applicators manually to eliminate any pressure build-up and

loosen the pressure regulator if the system is hot.

5. Use a spanner to unscrew the filter screw and remove it from the casing.

Summary of Contents for D4-L

Page 2: ......

Page 4: ......

Page 6: ......

Page 95: ...0 1 2 1 1 3 4 53 6 0 53...

Page 97: ...0 1 2 3 4 5 4 0 2 4 6 7 1 1 8 3 7 7 2 02 2 90 1 8 7 2 7...

Page 98: ...0 1 2 103 1 4 5 6 7 3 5 0 8 4 4 9 6 10 7 8 8 8 0 8 8 8 8 8...

Page 99: ...0 1 2 3 4 5 6 5 1 3 5 7 7 2 2 8 4 9 9 9 7 9 7 5 3...

Page 101: ...0 1 2 3 4 5 6 7 87 9 6 7 878 3 9 94...

Page 102: ...0 0 1 2 3 4 5 6 2 3 3 7 4 45...