Service manual

15

2.4. Changing of fuses

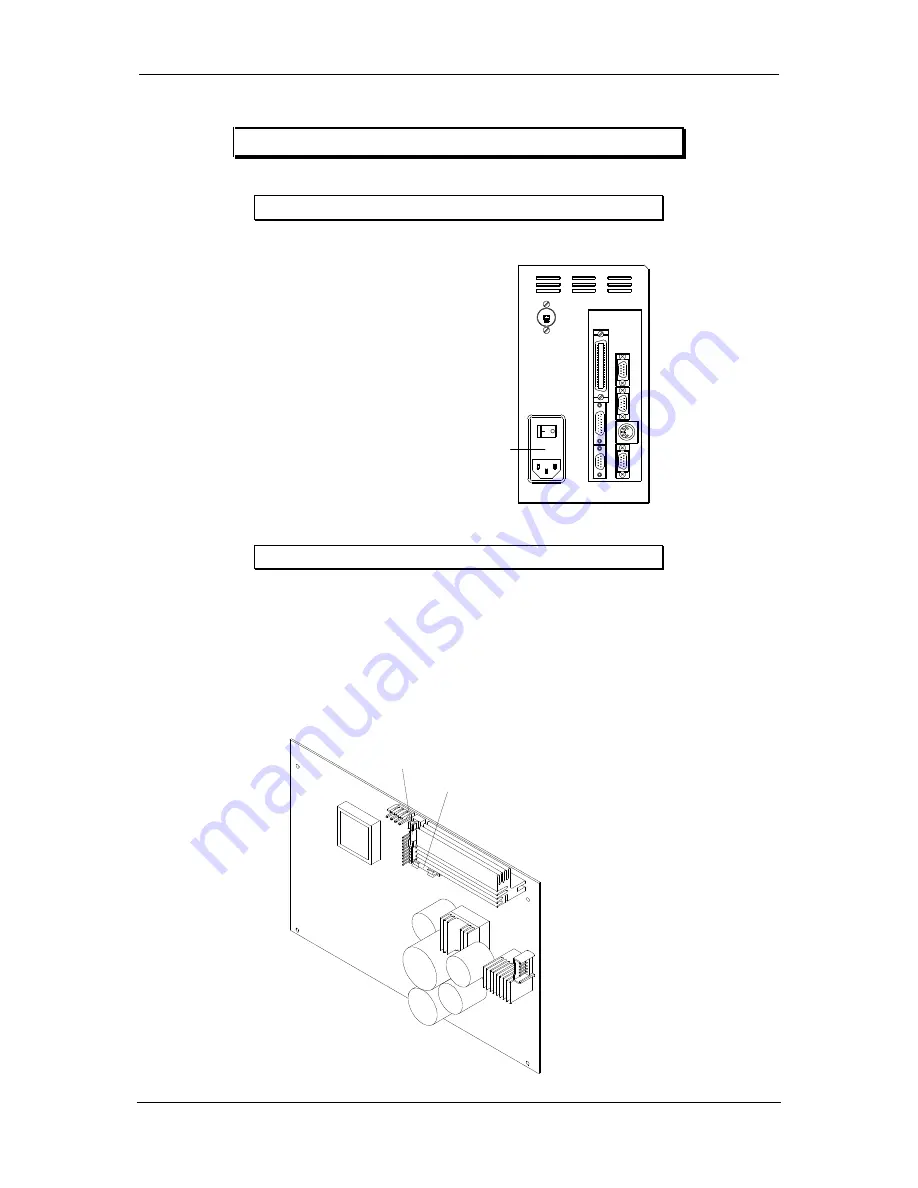

2.4.1. Primary fuse

solo rear panel:

The primary fuse is in the power line filter block and

accessible from outside.

After plugging out, the cover can be removed. There

behind you will find the fuse-switch, which has to be

drawn near to change the fuse.

F: fine-wire fuse T1,0A

power line filter block

F

2.4.2. Secondary fuse

Attention:

The machine should be opened by competent staff only.

Pug out before removing the left cover.

After removing the left cover the base plate is visible, whereon you will find two secondary fuses.

F1: fine-wire fuseT 1,0 A

fuse for 5 V and 12 V supply (CPU)

F2: fine-wire fuseT 6,3 A

fuse for motor voltage (35 V) and burning voltage (18 V res. 21 V) and

12 V supply (fan)

F1

F2