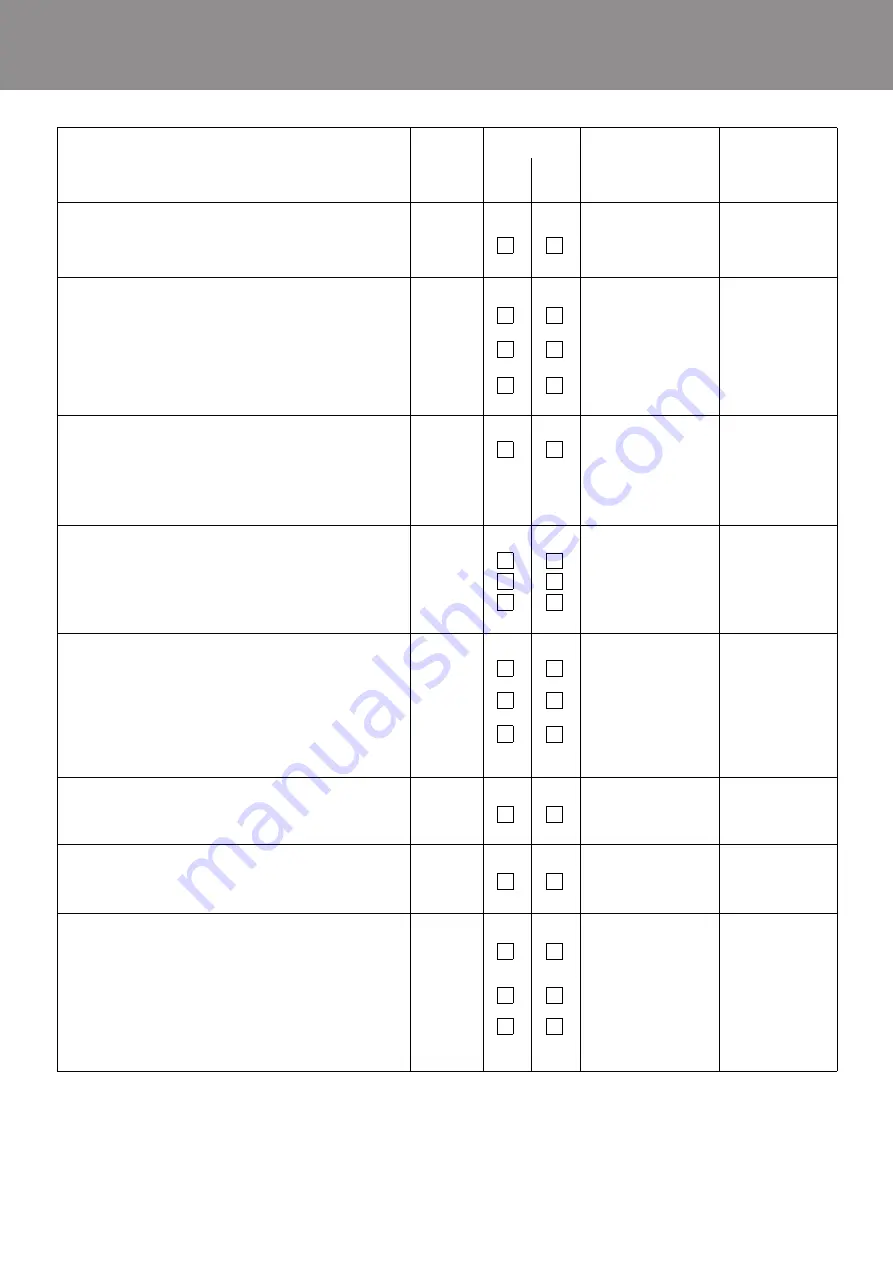

A-2

Maintenance plan

Check / Maintenance

Interval

Results

Note

Measured

values/

accomplished

repairs

OK

not

OK

During the maintenance, check all screw connections for

tightness (for corresponding torque values see Workshop

Manual).

1. Electrics (connections, components)

a) Examine electrical plug connections and the wiring

harness for visible damages, replace as required.

b) Verify the cables are secured properly with cable ties, if

necessary, retrofit or replace them.

c) Replace high-voltage contactor.

annually

annually

every12

years

2. Heat exchanger

Check for external damage, discoloration caused by over-

heating and leaks.

annually

Determine overhea-

ting cause as needed

(e.g. lack of water);

check overheat pro-

tection

3. Temperature sensors

a) Check temperature switch (water outlet) for function.

b) Check temperature limiter for function.

c) Replace temperature switch.

annually

annually

every 5

years

4. Burner head

a) Inspect hood for damage.

b) Earth conductor check/check grounding resistance

< 50m

Ω

against vehicle frame

c) Check isolation resistance > 50M

Ω

(at 1000V DC test

voltage)

annually

annually

annually

Replace damaged

parts.

5. Warning notes

a) Check warning labels.

Replace if absent or

unrecognizable.

6. Water system

a) If available, inspect water filter insert.

Clean as needed or

replace

7. Functional check

a) Check heater functionality.

b) Check operation of circulating pump for 120s in purge

cycle.

c) Check ground fault interrupter (AC ) or ISO guard (DC) for

function (if necessary acc. to manufacturers instructions).

annually

annually

annually

Check heat buildup

after at least 10 min

heater operation.

Summary of Contents for Thermo AC 070

Page 47: ...memos...