Installation of the heater - fitting of important assemblies

Thermo DC 200

26

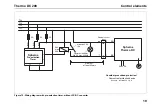

11.2. Connection to the vehicle's cooling system

The heating appliance is connected to the vehicle's cooling system

according to figure 17. The volume of coolant fluid present in the circuit

must be at least 35 liters. The water in the heating circuit of the heating

appliance must contain at least 30 to 60% of a branded antifreeze agent.

An up-to-date list of Spheros recommended anti-freeze agents can be

found on the Spheros website.

Basically, the by Spheros approved water hoses must be used. If this is

not the case, the hoses must at least comply with DIN 73411. The hoses

are to be laid without kinks and also rising where possible for the proper

bleeding of the heating appliance. The heater must be mounted below

the minimum water level of the cooling circuit. Hose connections are to

be secured with hose clamps against slipping off.

When installing the electric heater the direction of the flow of the cooling

water in the circuit is to be considered (see figure 17).

ATTENTION:

The specified tightening torques of the hose clamps used must be

adhered.

In the vehicle cooling system, or in the case of a separate heating circuit,

only overpressure valves with an opening pressure of maximum 2 bar

should be used.

Attention should be paid to the

careful bleeding of the cooling system

without usage of the circulating pump, before the first commissioning of

the heating appliance, or after the coolant fluid has been replaced.

For that the additional venting option via the vent screw item 4, figure 17

is to be used after the system has been filled and the pump has been

switched on.

The heat exchanger and the water hoses of the Thermo DC should be

pre-filled completely. Loosen the vent screw slightly until no air further

emerges, but only water. Then retighten the screw (tightening torque -

see figure 19).

ATTENTION:

If air bubbles are present, they could cause destruction of the car-

tridge heaters!

The heating appliance and pipes must be installed in such a way that

they ensure a static bleeding of the system.

The correct degree of bleeding results in an almost silently operating

circulation pump. An inadequate bleeding can lead during heating

operation to the switching-off of the heating appliance due to overhea-

ting.

Where the U 4855 / Aquavent 6000C circulation pump is used, the circu-

lation pump is automatically switched off ca. 10 seconds after switching

on, if the cooling agent is not present or there is blockage of the pump

impeller, and it can be started up again after ca. 2 minutes.

Where the U 4856 / Aquavent 6000SC circulation pump is used, the

circulation pump is automatically switched off ca. 45 seconds after swit-

ching on, if the cooling agent is not present or there is blockage of the

pump impeller, and it can be started up again after ca. 2 minutes.

ATTENTION:

Before commissioning the heating system, the water hoses, the

circulation pump and the heating appliance must be filled comple-

tely.

Only by Spheros recommended anti-freeze agents may be used.

Summary of Contents for THERMO DC 200

Page 4: ...IV Thermo DC 200...

Page 34: ...Technical data Thermo DC 200 30 For notes...

Page 35: ...memos...