- 19 -

3- Handling instructions

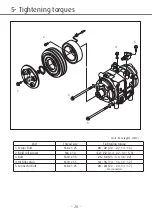

Flexible hose

High pressure

connector

T44375C

Low pressure

connector

T44373C

O-ring

569300-9200

Running-in operation

Whenever moving parts have been replaced, it

is necessary to run-in both the compressor and

the magnetic clutch.

Compressor running-in

Reassembled compressors must be run-in after

the leak test (see next page).

1. Check that the compressor contains the

specified amount of oil.

2. Install the compressor on the test bench.

3. Install the high pressure connector (T44375C)

and the low pressure connector (T44373C)

to the ports and tighten the bolts to the

specified torque.

Specified torque: 20 ~ 24 N·m

{2.0 ~ 2.4 kgf·m, 14 ~ 17 lbf·ft}

4. Connect the two connector ports using a

flexible hose.

5. Run the compressor at 1,000 rpm for at

least 30 minutes.

6. Replace the oil.

7. Repeat the leak test.

Magnetic clutch running-in

1. Install the clutch on the compressor.

2. Install the compressor on the test bench,

and operate the compressor by running the

system.

3. Maintain the compressor speed at 500 rpm.

Operate the A/C switch through the ON/

OFF cycle at least 50 times (

“

ON

”

for 10

seconds and

“

OFF

”

for 10 seconds).

ON

OFF

(50 times)

CAUTION!

While the compressor is being run-in in step

5 above, check the outside temperature of

the front head. If the temperature exceeds

80°C (176°F), stop the running-in operation.

Resume the operation when the head has

cooled.