MP80.PUB Version 1.07 17

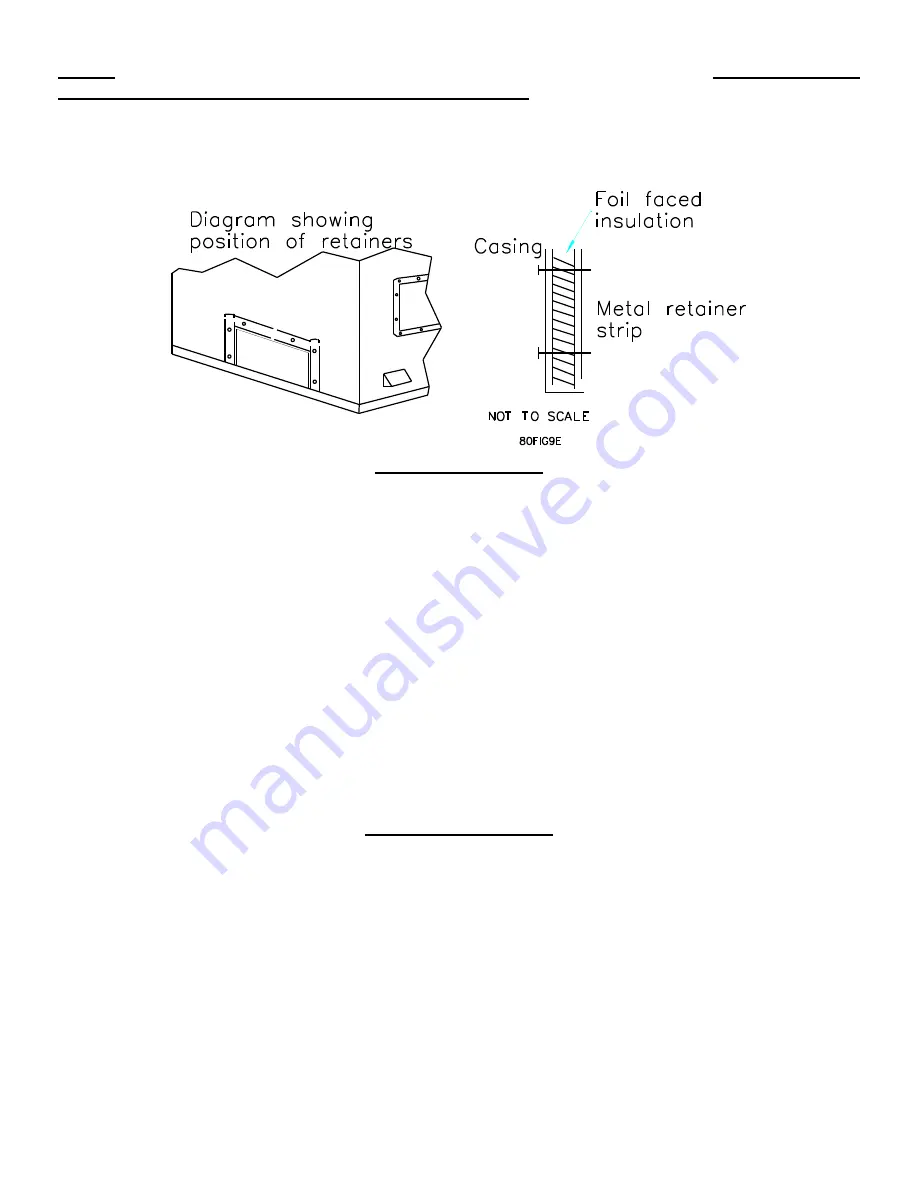

NOTE: After interconnect duct opening has been cut into the side of the MP80, insulation must be

fastened back to the furnace cabinet all around the opening. Use the metal strips provided to hold the

insulation tightly against the cabinet inside, to prevent the insulation from dislodging due to blower

induced vibration.

PRESSURE LOSS

Before any changes are made to the existing furnace system you must establish the working parameters of that

system. You can then insure that the addition of the add-on will not degrade the operation of the original

system and can confirm correct air flow will be maintained. Change all filters in the system to insure

maximum free air flow. Using an accurate manometer, check the static pressure at the end of a typical duct

near the exit to the house and then check the static pressure in the plenum above the existing furnace.

Pressure drop = Static pressure at furnace -(minus) static pressure at duct exit

Record the pressure drop of the original system.

Addition of the add-on furnace will add air flow resistance in the system. After installation is complete

measure the pressure drop in the same run measured before add-on installation. If the air flow has diminished

the blower speed should be adjusted to compensate. When using a belted blower the pulley size should be

changed or adjusted to speed up the blower. If the pulley size is adjusted measure the blower motor current to

insure that it is still within the nameplate rating. It may be necessary to replace the motor with a more

powerful motor. If a direct drive blower is used change to a higher speed. Do not change the blower size.

COMBUSTION AIR

Insure adequate combustion air allowing for all other exhausting type appliances in the dwelling (range hoods,

dryers, fireplaces etc.…). Introduce outside air if required to the furnace and allow for circulation via two

openings. In confined area, provide at least 1 sq. inch minimum free area for each 1000 BTU installed

capacity.

Summary of Contents for MP80

Page 2: ...MP80 PUB Version 1 07 2...

Page 26: ...MP80 PUB Version 1 07 26...