5

© Vallox Oy - All rights reserved

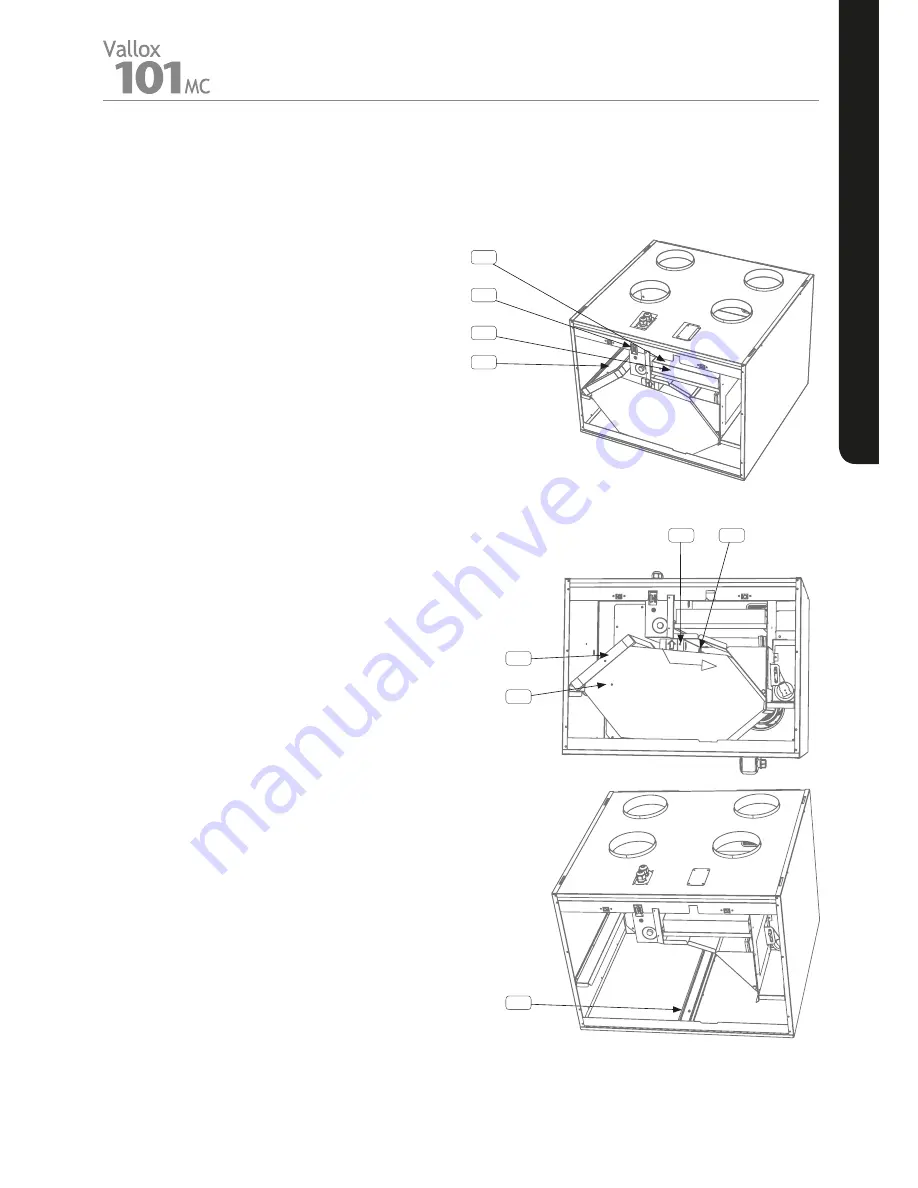

MAINTENANCE

The R model is shown in the figures.

In the L model, the parts are mirrored.

BEFORE BEGINNING

MAINTENANCE WORK

When you open the door of Vallox 101 MC, the safety

switch (S) cuts the power. Despite this, disconnect the

power supply plug anyway. Always disconnect the power

plug before starting maintenance on the Vallox 101 MC.

FILTERS

When the maintenance reminder becomes activated,

check the cleanliness of the filters and replace them if

required. The Vallox ventilation unit has three air filters:

• Class G4 coarse filter (A) filters insects, heavy pollen

and other relatively large foreign objects out of the

outdoor air.

• Class F7 fine filter (B) filters microscopic pollen and

dust particles out of the supply air.

• Class G4 coarse filter (C) filters the extract air and

keeps the heat recovery cell clean.

Using original Vallox filters ensures the best operation

of the ventilation unit and the best filtering results. The

filter replacement interval depends on the ambient dust

concentration. It is recommended that the filters be

replaced every spring and autumn, or at the very least

once a year.

HEAT RECOVERY CELL

Check that the heat recovery cell (D) is clean roughly

once a year when the filters are being replaced. Clean by

washing as required.

• Remove the sealing strip (E) above the heat recovery

cell in the direction of the arrow. Also remove the

extract air filter (C).

• Lift the heat recovery cell and pull it out of the unit.

IMPORTANT! Handle the cell carefully! For example, do

not lift the cell by the layers. The cell layers are very thin

and easily damaged.

If the heat recovery cell is dirty, clean it by immersing it in

water containing a small amount of a mild detergent. Rinse

the heat recovery cell clean with a water spray. When all

the water has drained from between the layers, the heat

recovery cell can be installed.

• Ensure that the lower support (F) is in place between

the knobs at the bottom of the unit before the heat

recovery cell is installed.

• Push the heat recovery cell in place. Also push the

sealing strip (E) in place so that the strip is supported

by the corner bracket (G) at the rear. Lastly, install the

extract air filter (C) in place.

S

A

B

C

E

G

C

D

F