VALLOX 280 SE

MAINTENANCE INSTRUCTIONS

13

3.

Maintenance instructions

General

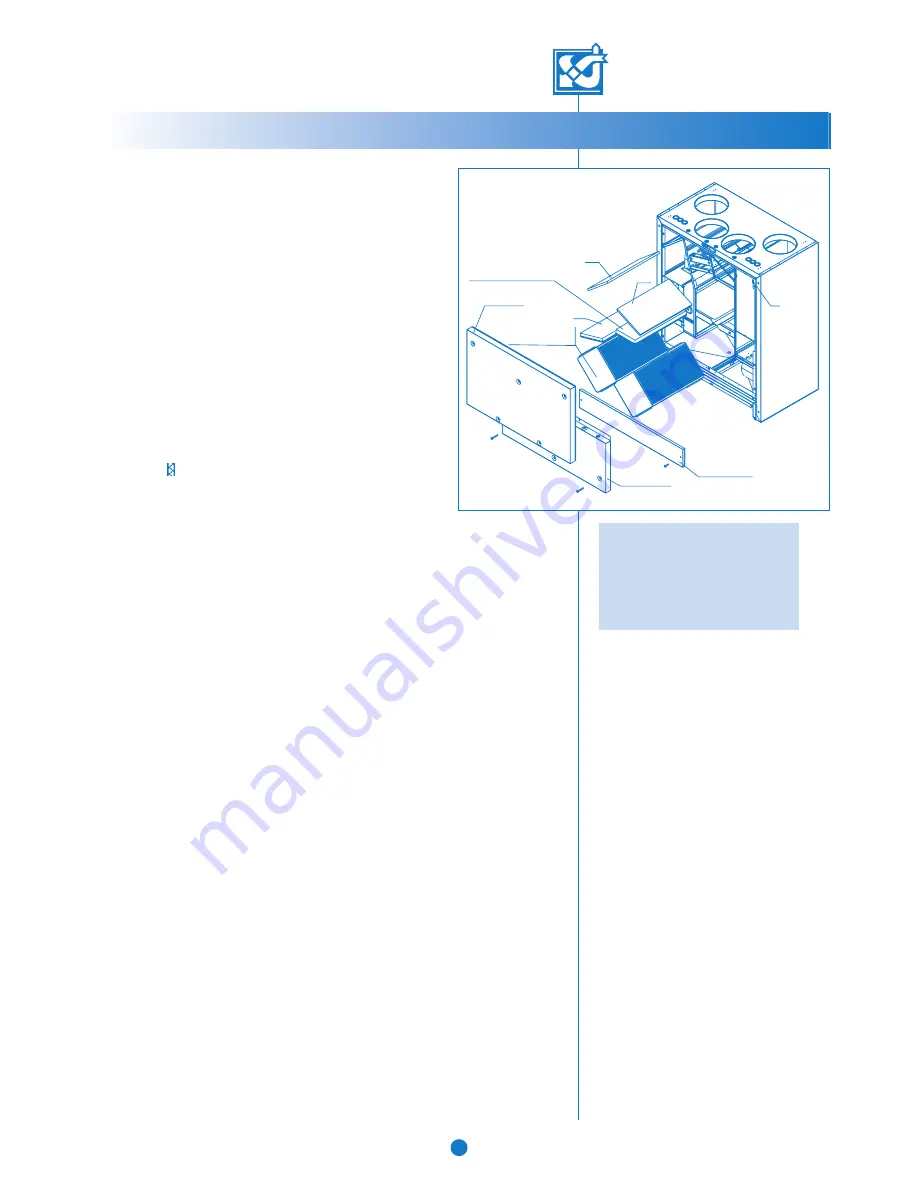

• The unit has a two-part door. When you take off the upper

door, the safety switch (T) turns voltage off. The upper door

is always opened first and shut last.

• If maintenance is only done for the filters, it is enough to

take off the upper door. When also other maintenance

activities are done, both doors have to be taken off.

3.1. Filters

• The unit comes standard with G3 class coarse filters for

outdoor and extract air and an F7 class fine filter for supply

air. An F5 class fine filter for extract air is available as an

option. The filters need to be cleaned or replaced with new

filters at regular intervals (2…4 times a year) and

depending on dirtiness.

• If the unit is equipped with filter guards, they show a

symbol ( ) in the main display of the control panel or in

remote monitoring when the filters need to be cleaned and

replaced with new ones when necessary.

REMEMBER!

Clean the filters when needed, preferably

2…4 times a year. Set the maintenance re-

minder interval according to your needs (de-

pendent on the cleanliness of outdoor and in-

door air). See the instructions in Section 2.3.21.

© VALLOX • We reserve the right to make changes without prior notification.

Filter maintenance:

• Open the fixing screws of the upper door of the unit.

• Lift the door off.

• Check if the filters are clean.

• A G3 class (blue and white) filter can be cleaned with +25

°

C...+ 30

°

C water

and washing-up liquid. It must not be washed or dried roughly, but by pressing

gently. When washing is done properly, filters stand cleaning 4 to 5 times.

• F5 and F7 class filters (fabric filters) cannot be washed, but they can be cleaned

by carefully blowing compressed air against the direction of contamination (F5

is optional). When necessary, the filters have to be replaced with new ones. The

recommended replacement interval, depending on the circumstances, is 2 to 4

times a year.

Other cleaning

• In connection with maintenance, also check the internal cleanliness of the unit:

preheating and post-heating units, bottom reservoir and internal casing.

Remove dirt with a vacuum-cleaner, brush, damp cloth, etc.

•

It is absolutely forbidden to let water run into the electrical devices!

3.2. Heat recovery cells

• The heat recovery cells in the unit may get dirty in spite of the filters. Because of

this, the cleanliness of the cells must be checked at regular intervals,

approximately once a year. It is recommended to do the checking in connection

with filter maintenance.

• The cells can be taken out of the unit by pulling the ears on the end plates

outward. Dirty cells can be washed either by first spraying a washing-up liquid

on the cells or by sinking them in water containing washing-up liquid. After this,

rinse them clean with a water shower. Let the cells drain dry and then mount

them back in place. When remounting the cells, pay attention to the “up”

stickers in the cells.

Upper door

G3

G3

F7

F5 (option)

Heat recovery cell

T

Lower door

Socle moulding