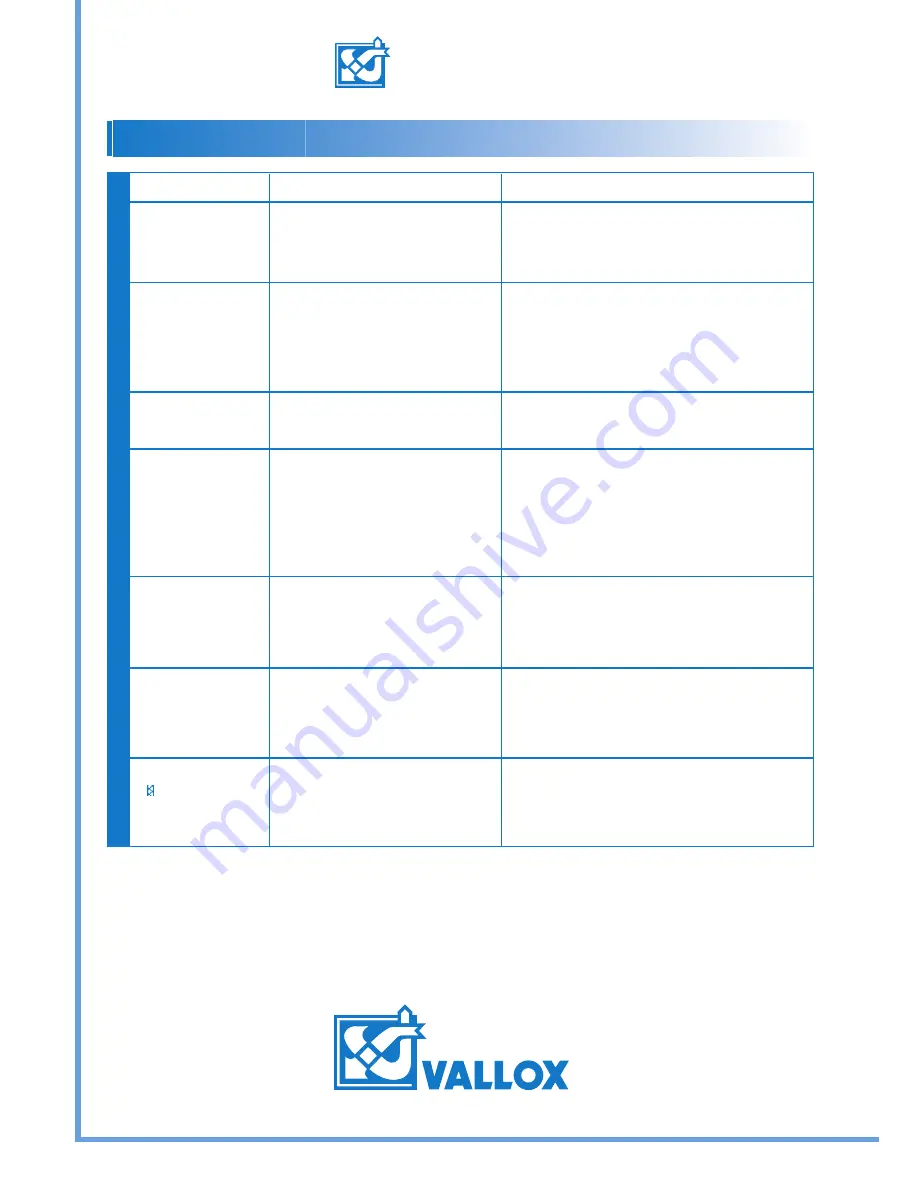

"Bus fault" message is

displayed and the unit ope-

rates at speed 1 (check the

fan speed).

• Wiring fault in the carbon dioxide sensor,

in the control panel or in the humidity

sensor.

9

• Contact a maintenance company. The connections have

to be checked and corrected if necessary.

"Freezing alert" message is

displayed and the unit is

stopped.

• Anti-frost of the water-circulating radiator is

active.

NOTE! If there is no non-freezing solution in the

water of the radiator, the radiator is at risk of

freezing.

10

• Immediately troubleshoot the situation. Consult a

maintenance company to find out if there is any non-

freezing solution in the radiator. Check if the circulation

pump is broken, the boiler out of operation etc. The

situation may pass by itself as soon as supply air

temperature exceeds 10 degrees, but do not wait till it

happens.

The desired automatic

adjustment does not stay

on.

• There is a fault in the humidity or carbon

dioxide sensor, one of the sensors is

broken or missing.

11

• Contact a maintenance company. The sensor installation

and connections have to be checked. (The sensors are

optional.)

The unit does not work,

the fans are not running

and no indicator light is lit

in the control panel.

• The door switch may be broken, or the

door is possibly not quite closed.

• The unit is out of power, e.g. because a

fuse has blown.

• The glass tube fuse (located in the control

card behind a protecting plate) the

electronics inside the unit may have blown.

12

• Check the door switch and fuses. The unit includes a

T800 mA glass tube fuse.

• If needed, contact a maintenance company (e.g. to

check the glass tube fuse).

The unit does not obey the

control panel.

13

• Remove or switch off the power supply fuse of the unit,

located in the distribution panel, or the circuit breaker.

Wait for 30 seconds and put the fuse back, or switch the

circuit breaker on. If this does not help, contact a

maintenance company.

"Carbon dioxide alarm"

message is displayed and

the unit is stopped.

• Carbon dioxide alarm. Carbon dioxide

content has exceeded 5000 PPM for more

than two minutes. May be caused by a

fire.

14

• If there is a fire, take the necessary steps.

• You can put the unit in working order by disconnecting the

plug from the wall socket, waiting for 30 seconds and

connecting the plug again.

• Check the cleanliness of the filters and the unit. If needed,

clean or replace the filters.

15

© VALLOX • We reserve the right to make changes without prior notification.

1.09.372E/19.8.2008/PDF

VALLOX 280 SE

Vallox Oy FIN-32200 Loimaa Finland Tel358 2 7636 300 Fax +358 2 7631 539

Internet: www.vallox.com.

FAULT SITUATIONS

After a power failure, the unit starts at minimum fan speed.

All the other selected adjustments and setpoints remain in the memory of the unit.

The filter guard symbol

( ) is displayed and the

unit operates otherwise

normally.

• Pressure in the filter guard (pressure

difference switch) has exceeded the

setpoint.

SYMPTOM

REASON

DO THIS