VALLOX 90 SE

© VALLOX • We reserve the right to make changes without prior notification.

Vallox Oy • Myllykyläntie 9-11 • FI-32200 Loimaa • Tel. +358 10 7732 200 • www.vallox.com

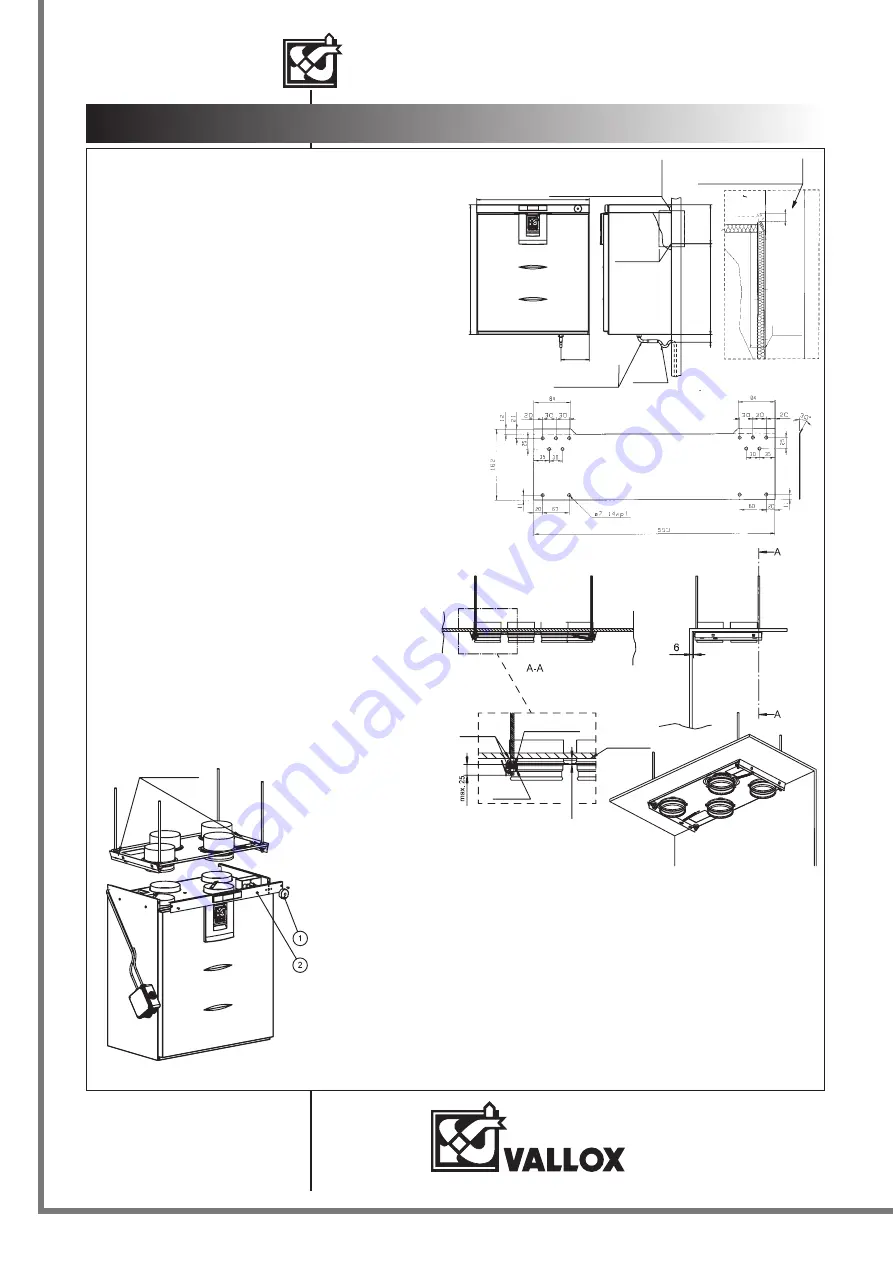

LOCATION OF VALLOX 90 SE

1.09.331E/9.4.2013/PDF

597

68

8

150

40

48

2

206

LOWER EDGE

OF BRACKET

THE LEAD-IN OF ELECTRIC WIRES

CAN BE DONE FROM BOTH SIDES OF

THE UNIT.

Condensing water

outlet and water seal

Cu ø12x1

DURING MOUNTING THE UNIT RISES 10

MM HIGHER THAN THE FINAL HEIGHT.

10

160

Lower edge

of bracket

Installation

VALLOX 90 SE has to be mounted in a place where temperature

does not fall below +10 ºC. Without protective casing, the unit

must be located in a place with no acoustic disturbance: storerooms,

technical rooms etc.

Wall mounting

VALLOX 90 SE is mounted on the wall with a fixing plate as

shown in the adjacent figure.

Wall construction

When fixing the unit, take the wall structure into account. Avoid mounting

the unit on a hollow, echoing dividing wall and on a bedroom wall

because of sound conduction, or prevent sound conduction.

Wall mounting plate

Condensing water

The delivery includes a water seal. With a pipe connected to the water seal,

water condensing from extract air can be led to a floor drain (not straight

to the drain) The pipe must not rise after the water seal. The unit has to be

mounted level with the horizontal in order to ensure that condensing water

can get out of the unit.

Ceiling mounting/ceiling mounting plate

Fastening of ceiling mounting plate to ceiling

The ceiling mounting plate is mounted straight, and it has to be fastened

so that there is a space of circa 6 mm between the back edge of the

ceiling mounting plate and the wall (Figure 1).The ventilation unit

becomes attached to the back wall. Minimum distance between the lower

edge of the ceiling mounting plate and the ceiling of the room is 14 mm.

Wit this distance, there will be a vent of circa 2 mm between the upper

edge of the mounted unit and the ceiling.

The ceiling mounting plate is fixed to the ceiling with M8 thread bars.

When the thread bars have been fastened to the ceiling, first turn the nuts

into the thread bars and lift the ceiling mounting plate in place. Then push

a rubber damper and washer to each thread bar, all the way into the cup

of the plate, and turn the nut. Shorten the lower ends of the thread bars so

that they will be at no more than 25 mm from the lower surface of the

ceiling mounting plate. NOTE! Shortening the thread bars can only be

done before mounting the ceiling mounting plate. The maximum length of

a thread bar from the lower surface of the ceiling is the space between the

lower surface of the ceiling and the lower surface of the ceiling mounting

plate + 25 mm.

Mounting of ventilation unit to ceiling

mounting plate

Before lifting the unit to the ceiling mounting plate, detach

the following items from the unit (Figure 2):

1. Thermostat knob (SC unit)

2. Front panel (leave it hanging from the measurement

hoses)

Put the cables of the connection box into the slot in the

upper part of the side plate and pull the connection box

next to the unit so that the cables remain in the slot. Make

sure that the duct outlets for the unit’s extract air duct and

for the duct coming from the outside to the unit are

equipped with condensing water insulation. Lift the unit in

place to the ceiling mounting plate till both locking wings

lock to the outer edge of the side plate of the unit. Do a

visual check of the tightness of the duct outlets and of the

correct moving of the measurement hoses and electric

cables. Fasten the front panel and the knob of the

thermostat (SC unit) back in place.

Attention!

To prepare for external connections from the

electrical box of the unit, you can fix the

electrical box on the wall beside the unit.

Air flow measurement outlets

The fixed measurement outlets for air flow are

located behind the nameplate of the unit. You

can measure the total pressure of the supply

and extract air ductwork at the measurement

outlets, using a differential pressure instrument.

Pressure readings and the unit’s air volume

tables show volume air flows at various

adjustment positions. The red measurement

hose is on the pressure side and the black hose

on the suction side of the fan.

Figure 1

Nuts

Damper rubber

Lower

surface

of ceiling

Washer

at least 14

wall

ceiling

Locking wing

Figure 2