VALLOX 90 SE

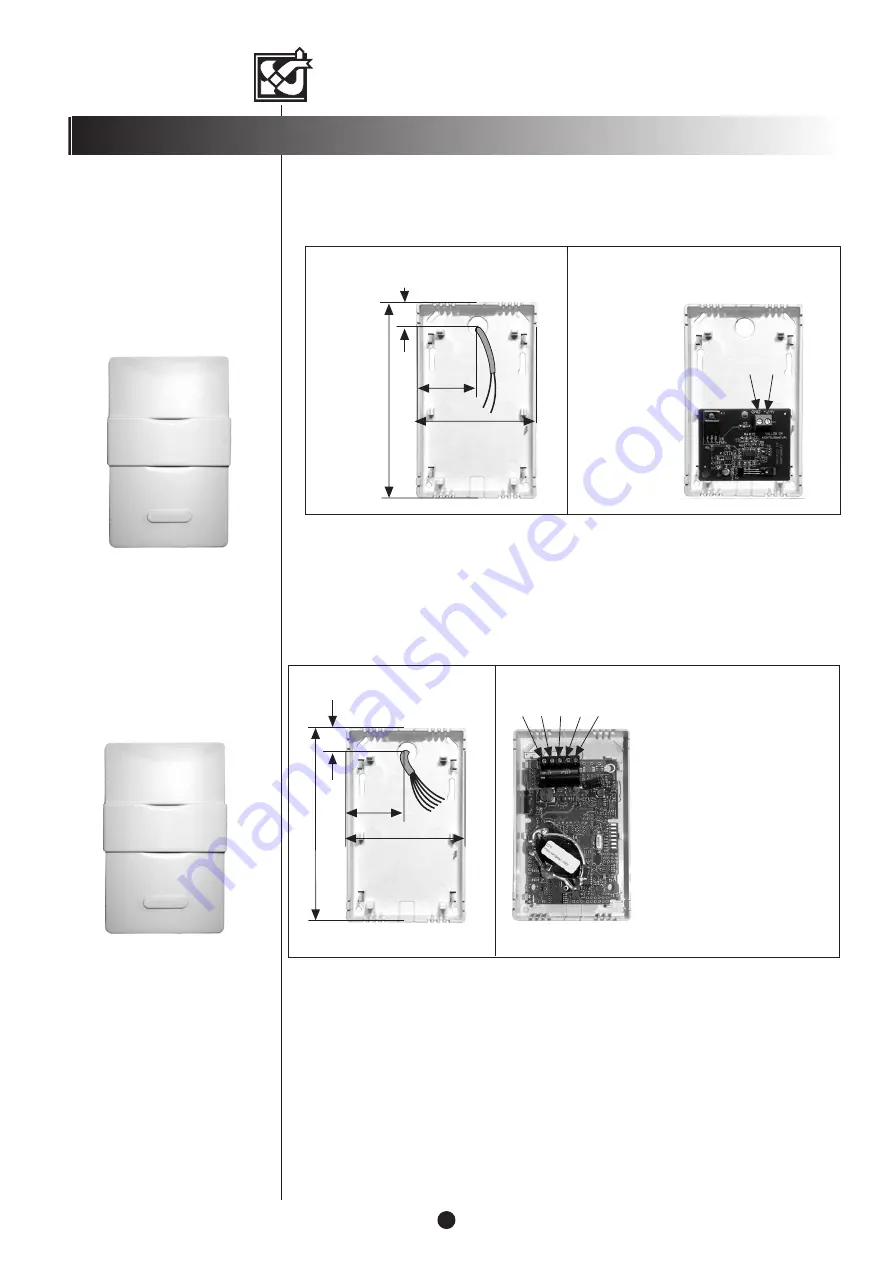

Surface mounting

Wiring

Cable: 2 x 0.5 mm

2

Electronics board

of %RH sensor

Surface mounting

© VALLOX • We reserve the right to make changes without prior notification.

Base plate

of sensor

14

125

38

76

Mounting and wiring of humidity sensor

Mounting and wiring of carbon dioxide sensor

Base plate of the CO

2

sensor

14

125

38

76

Carbon dioxide sensors

• Carbon dioxide sensors are connected

individually.

• When the first carbon dioxide sensor has

been connected to the system, the unit is

switched on. After this, the unit gives the

sensor an address. Follow the same steps

for other carbon dioxide sensors.

Electronics board of the CO

2

sensor (model may vary)

Humidity sensors

• When mounting two or more humidity

sensors, connect them to the terminal

block of the connection box by

connecting the first humidity sensor to

%RH1, in place of the 6K8 resistor in

the terminal block (remove the resistor

in this case), and the second humidity

sensor to %RH2. See the electrical

diagram.

S +

6

MOUNTING OF SENSORS

The sensor is wired straight from the electrical connection box of the unit.

The CO

2

sensor is wired directly from the VALLOX 90 SE connection box, or it can be wired

in series with another CO

2

sensor or control panel (see External electrical connections on

page 11).

Wiring

Cable:

NOMAK 2 x 2 x 0.5 mm

2

+ 0.5 mm

2

NOTE!

Faulty coupling of the (+) wire destroys

the carbon dioxide sensor!

1 = orange 1

= +

2 = white 1

= -

3 = orange 2

= A

4 = white 2

= B

5 = metal

= signal ground M

ca. 21 VDC

}

1 2 3 4 5

+ – A B M