16

Release 07/22

MashFlex

Wire Rope Safety Barrier

Wire Rope Safety Barrier

Wire Rope Safety Barrier

ASH LE

I N G A L C I V I L P R O D U C T S

ASH LE

I N G A L C I V I L P R O D U C T S

7.4 Emergency Dismantling

Due to the dynamic nature of a traffic accident, safety

barriers may inhibit access of rescue personnel to the

vehicle, or crash site, and may need to be moved.

Interfering with the WRSB at a crash site may be

hazardous due to the potential latent tension in the

cables and all de-tensioning should be conducted by

trained personnel at the tension bays.

In an emergency situation, where waiting for a trained

WRSB install crew is not viable, cutting the cables may

be deemed absolutely necessary. Please note, this can

be a very dangerous task and a thorough risk assessment

should be conducted before the cutting commences.

If the cables are under tension, any interference may

cause them to release.

There are two options to cut the cable, the

preferred option is to cut the turnbuckle on each

cable. Turnbuckles should be located every 300m

approximately. Alternatively, the cables can be cut with

a disc grinder.

Before commencing any cutting:

• Ensure all personnel are in a safe location.

• Do not stand on the concave side of restrained cables.

• Do no cut in close proximity to the crash scene.

A video demonstration of how to work

with, and around, high tension WRSB

can be viewed at:

https://www.ingalcivil.com.au/wrsb-

emergency-cut.

8.0 Product Storage

Most components of the MashFlex system are galvanized

steel. It is important that stored galvanized work is stacked

so that each item is well ventilated and can adequately

drain rainwater from its surfaces.

Poor storage of galvanized product can give rise to wet

storage staining (white rust) which is caused by water

(rain or condensation) in badly drained or ventilated

conditions. This can occur very quickly, particularly in

warm, humid conditions.

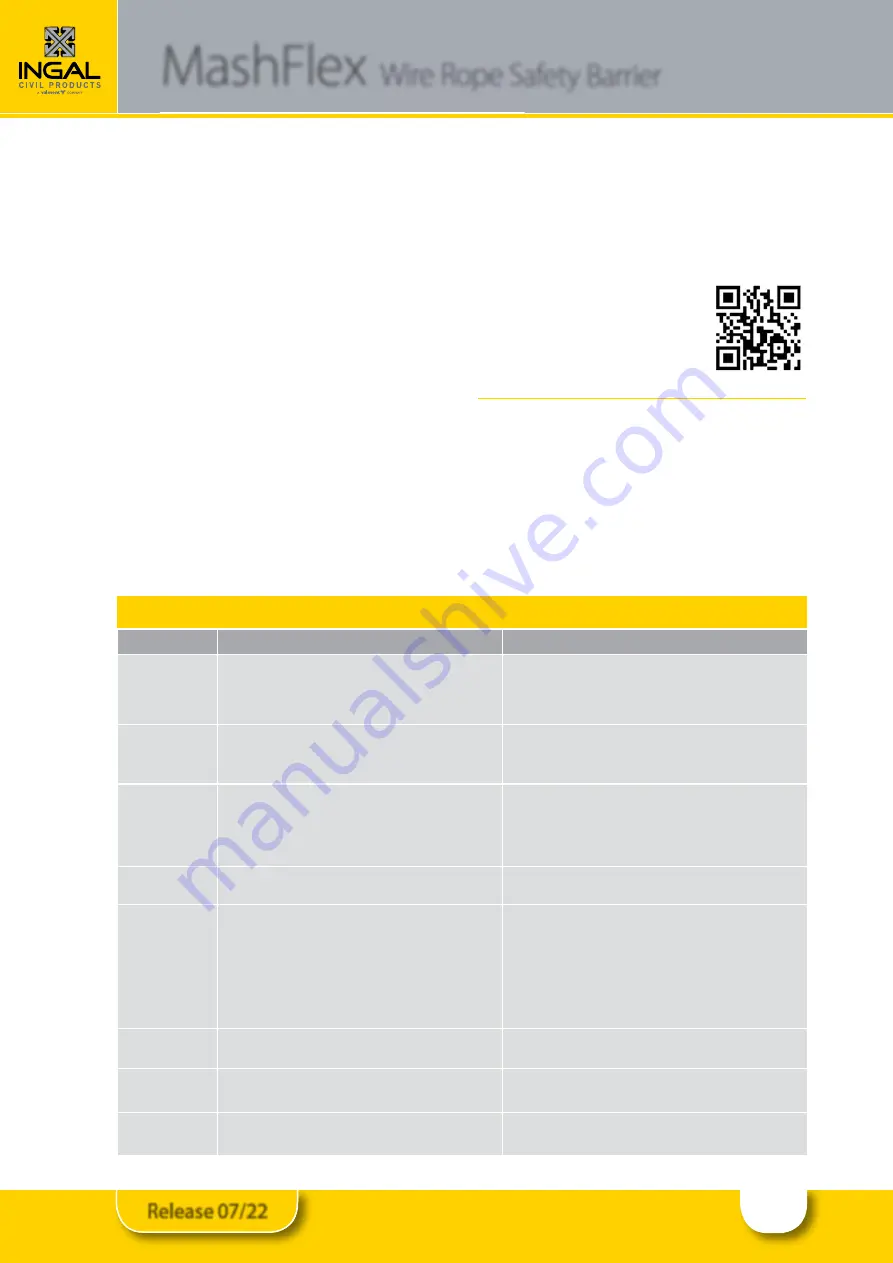

Table 6: Damage Assessment

Type of Defect

Description of the Defect

Action to be Taken

Galvanizing damage

on Posts.

The sum total of the damaged or uncoated areas does not exceed

10cm

2

(0.5% of the total surface area).

The sum total of the damaged or uncoated areas exceeds 10cm

2

(0.5%

of the total surface area).

An organic zinc rich epoxy paint, complying with AS/NZS 3750.9, is to be

applied to the repair areas in two coats.

The post is to be replaced.

Galvanizing Damage

on Wire Rope Cable

The wire rope is nicked or gouged to less than 10% depth.

The wire rope is nicked or gouged greater than 10% depth.

An organic zinc rich epoxy paint, complying with AS/NZS 3750.9, is to be

applied to the repair areas in two coats.

The wire rope section is to be replaced.

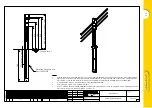

Mechanical Damage

on Wire Rope Cable

(Refer drawing

WR-STD-59)

Any rope length containing more than 1 broken wire.

Any rope where the diameter is reduced by more than 10% by abrasion.

Any rope which has been crushed or flattened by more than 10% of its

nominal diameter.

The rope section is to be replaced.

The rope section is to be replaced

The rope section is to be replaced.

Mechanical damage

on Posts.

The post is distorted.

The post is to be replaced.

Damaged End Fitting

There is damage to the thread of the fitting, however tension can be

maintained in the wire rope system without relying on the fitting.

There is damage to the thread of the fitting and tension cannot be

maintained in the wire rope system without relying on the fitting.

The fitting is cracked.

The body of the fitting is distorted.

There is no requirement for immediate replacement. The location of the

fitting should be noted and scheduled for replacement during routine

maintenance.

The fitting is to be replaced.

The fitting is to be replaced.

The fitting is to be replaced.

Damaged Tension

Fitting

The fitting is cracked.

The body of the fitting is distorted.

The fitting is to be replaced.

The fitting is to be replaced.

Damaged Driven

Sleeve

Sleeve opening is significantly distorted from yielding post.

Sleeve is dislocated causing new post to be out of alignment.

Install a new sleeve 200mm upstream or downstream of damaged sleeve.

Install a new sleeve 200mm upstream or downstream of damaged sleeve.

Damaged Post

Footing

Footing cracked causing replaced post to be out of alignment.

Footing is dislocated causing replaced post to be out of alignment.

Install a new footing 200mm upstream or downstream of damaged footing.

Install a new footing 200mm upstream or downstream of damaged footing.

Summary of Contents for INGAL MashFlex MASH TL3

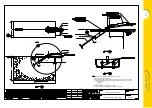

Page 11: ...11 Release 07 22 MashFlex Wire Rope Safety Barrier Figure 10 Figure 11 Figure 12 Figure 13...

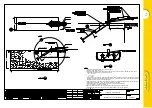

Page 12: ...12 Release 07 22 MashFlex Wire Rope Safety Barrier Figure 14 Figure 15 Figure 16 Figure 17...

Page 19: ...19 Release 07 22...

Page 26: ...26 Release 07 22 Notes...

Page 27: ...27 Release 07 22 Notes...