Wire Rope Safety Barrier

Wire Rope Safety Barrier

ASH LE

I N G A L C I V I L P R O D U C T S

ASH LE

I N G A L C I V I L P R O D U C T S

3

Release 07/22

MashFlex

Wire Rope Safety Barrier

3.0 Technical Data

3.1 MashFlex Performance

Wire rope safety barriers are classified as flexible barriers

and consideration must be given to the expected

movement of the barrier when impacted.

The design of a WRSB should include an assessment of

the mass of the impacting vehicle, its speed and angle

of impact. Whilst rigorous crash testing is undertaken

to evaluate the performance of roadside barriers, the

deflection results obtained during testing should not be

considered an exact distance, but rather as a single point

within the range of deflections that can be expected.

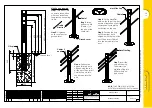

3.2 Working Width

The working width is the maximum width that is required

to prevent an impacting vehicle from colliding with an

object behind a road safety barrier system. This includes

the dynamic deflection and the extra width due to the

roll of an impacting vehicle. The roll of a vehicle is an

important consideration in shielding a fixed object hazard

such as a utility pole or bridge support. Refer to Table 2 for

tested working widths and Fig. 2 for more detail.

3.3 Dynamic Deflection

The dynamic deflection is defined as the largest

transverse deflection of a road safety barrier system

recorded during crash testing. Refer to Table 2 for tested

deflections and Fig. 2 for more detail.

If the available space between the hazard and the barrier

is not adequate, then the barrier can be stiffened in

advance of, and alongside the hazard by reducing the

post spacing. Other factors that can have an influence on

the deflection of the barrier include tension in the wire

rope cables, horizontal curvature and installation length.

3.4 Footing Selection

The post footing provides lateral support to the post

during impact ensuring the post yields by bending near

ground level. The type and size of footing is dependant

upon the surrounding soil type and distance to the

embankment rounding point.

Table 1 provides guidelines for the construction of

concrete post footings for varying site conditions. If using

the Driven Sleeve footing option, please refer to drawing

WR-MF-002 and asset owner acceptance conditions

prior to installation.

Figure 2: Barrier Displacement Terminology

Allowance for

system width

and/or vehicle roll

Working Width

System Width

Dynamic Deflection

(may be 0m with rigid barriers)

Safety

Barrier

Limit of

Dynamic

Deflection

Initial position of barrier

Ve

hic

le

ro

ll i

s s

lop

e l

ine

Object

requiring

protection

from impact

De

fle

cte

d

po

sit

ion

of

ba

rri

er

Summary of Contents for INGAL MashFlex MASH TL3

Page 11: ...11 Release 07 22 MashFlex Wire Rope Safety Barrier Figure 10 Figure 11 Figure 12 Figure 13...

Page 12: ...12 Release 07 22 MashFlex Wire Rope Safety Barrier Figure 14 Figure 15 Figure 16 Figure 17...

Page 19: ...19 Release 07 22...

Page 26: ...26 Release 07 22 Notes...

Page 27: ...27 Release 07 22 Notes...