Wire Rope Safety Barrier

Wire Rope Safety Barrier

ASH LE

I N G A L C I V I L P R O D U C T S

ASH LE

I N G A L C I V I L P R O D U C T S

9

Release 07/22

MashFlex

Wire Rope Safety Barrier

Vehicles impacting the end of the terminals will normally

continue behind and beyond the barrier and may

encounter non-traversable terrain or other roadside

hazards. It is recommended that the guidelines as stated

in AS/NZS 3845 for the installation of gating safety barrier

end terminals be observed.

AS/NZS3845 requires that a Hazard Free Zone

‘immediately behind the terminal… should be

reasonably traversable and free from fixed object hazards.

If a clear runout is not possible, this area should be similar

in character to adjacent unshielded roadside areas.’

6.4 Construction of Anchor Blocks

MashFlex is available with a variety of anchor block

designs. These include;

1. Default block - Type 3 - WR-STD-64

2. Poor soil conditions - Type 1 - WR-STD-62

3. Spacial limitations - Pier - WR-STD-82

The selection of a suitable design will depend upon soil

type, refer anchor drawings for minimum conditions.

Typically, the alignment of the anchor block will follow

the same alignment as the length of need section. If site

conditions require the anchor block to be offset to the

length of need section, a 200m radius can be introduced

upstream from the end anchor until the desired offset

angle is achieved. The fence can then be tapered at a

constant rate to achieve the required offset distance.

The construction sequence is as follows;

1. Excavate the anchor hole in accordance with the

chosen anchor block drawing.

2. If installing the rectangular anchor block, clip out several

grids of the reomesh square to fit over the anchor

bracket as shown in Ingal drawing WR-STD-62.

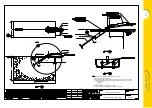

Figure 4: Clipping of Reomesh

3. Attach 3 off M20 x 550mm hook bolts to the base of

the anchor bracket using 2 off M20 nuts per hook bolt.

One M20 nut is used either side of the anchor bracket

to secure each hook bolt.

4. Using formwork, suspend the anchor bracket and

reomesh, ensuring the anchor bracket levelling plate

is at the same longitudinal grade as the roadway. The

position of the anchor bracket is to be in accordance

with the anchor block drawing.

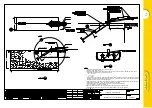

Figure 5: Placement of Anchor Bracket

5. To prevent flotation or dislodgement during the

concrete pour, drive a shortened star picket into the

base or side of the excavation and use tie wire to

secure the bracket.

6. Pour concrete into the excavation and vibrate. Ensure

that the anchor bracket has remained secure.

7. Trowel the surface of the anchor block and shape to

provide fall way from the anchor bracket.

Figure 6: Trowelling of the Anchor Block

6.5 Construction of Concrete Post Footings

1. Establish post spacing in accordance with expected

dynamic deflections and excavate postholes to the

dimensions in accordance with Table 1. Note that the

height of the footing must be within 20mm of the

design reference height.

If the sides of the postholes are seen to fall away into

the hole upon coring/excavation, creating a ‘coning’

or tapering of the hole, the hole depth should be

increased to 750mm.

2. Pour concrete into each hole.

Summary of Contents for INGAL MashFlex MASH TL3

Page 11: ...11 Release 07 22 MashFlex Wire Rope Safety Barrier Figure 10 Figure 11 Figure 12 Figure 13...

Page 12: ...12 Release 07 22 MashFlex Wire Rope Safety Barrier Figure 14 Figure 15 Figure 16 Figure 17...

Page 19: ...19 Release 07 22...

Page 26: ...26 Release 07 22 Notes...

Page 27: ...27 Release 07 22 Notes...