45

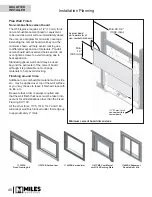

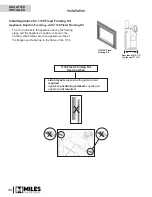

Install Appliance with 1130 Fixed Framing Kit

Part of the 1130 Fixed Framing Kit installs at the time of

framing the appliance.

The side brackets provided loose with the appliance

are not needed with this kit.

The 1130 Fixed Framing Kit is not compatible with

any other trim or door kits.

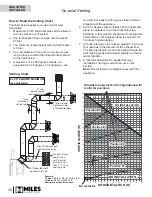

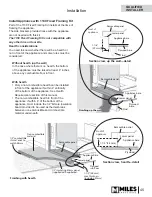

Hearth considerations

You need to know whether there will be a hearth or

not in front of the appliance and some rules must be

considered:

Without hearth (up the wall)

In the case where there is no hearth, the bottom

of the appliance must be raised at least 4” inches

above any combustible fl oor in front.

With hearth

•

Only a non-combustible hearth can be installed

in front of the appliance if within 4” vertically

of the bottom of the appliance. See

Hearth

Requirements

section of this manual.

•

The non-combustible hearth in front of the

appliance, if within 4” of the bottom of the

appliance, must include the 1/2”

Micore

insulation

board provided to be used as thermal break

between non-combustible and combustible

material underneath.

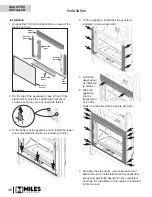

Installation

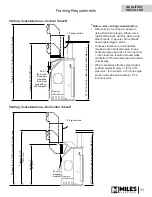

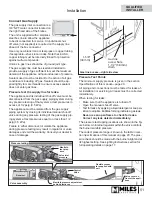

Section view, up the wall—detail

Lower panel

Removable panel

1-1/8”

(29 mm)

Front of

appliance

Stud

Plywood base

Appliance base

Lower panel

Removable panel

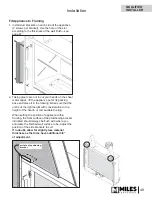

Finishing up the wall

Stud

Plywood

base

Appliance base

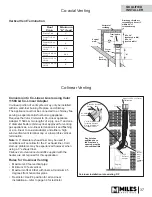

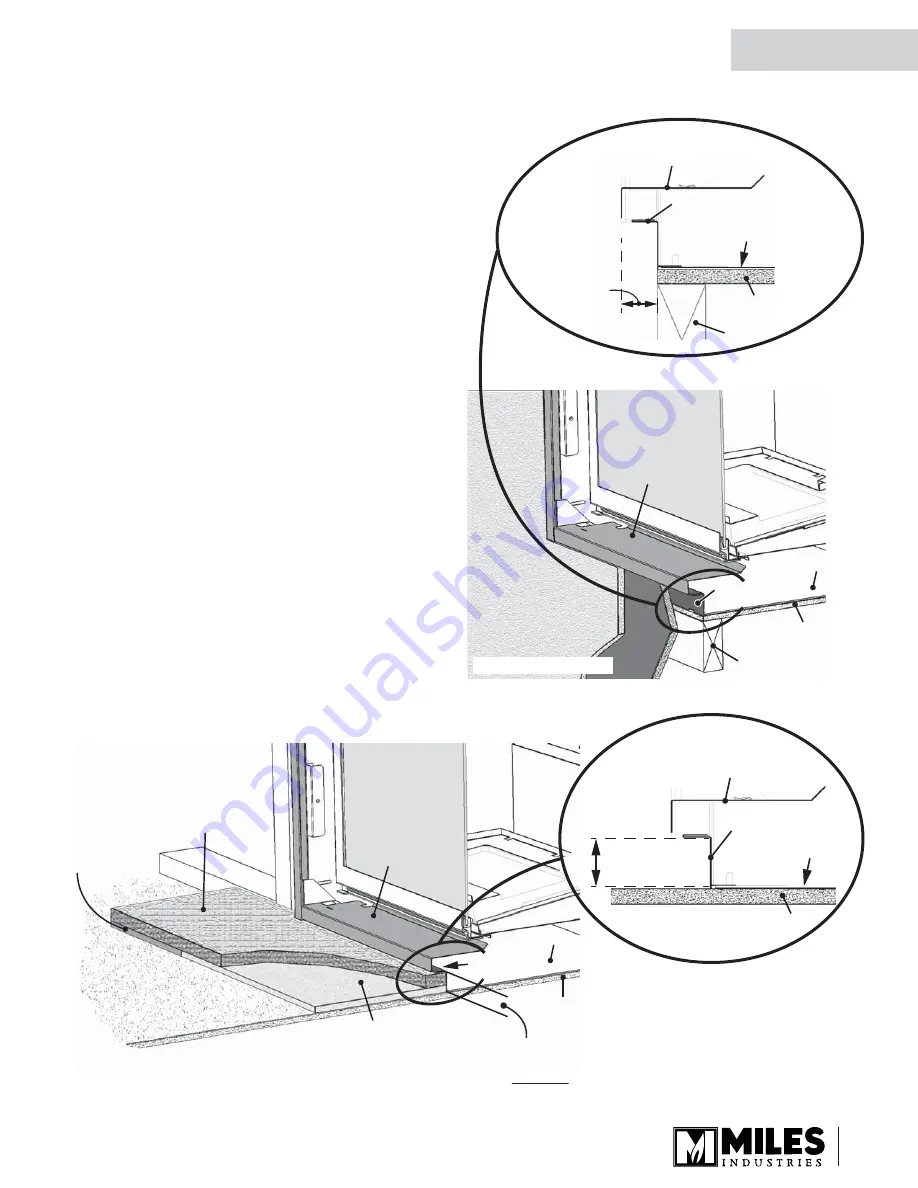

Section view, hearth—detail

Lower panel

Removable panel

Finishing with hearth

Non-combustible

material

1/2” insulating

Micore

panel

(supplied with appliance)

Plywood

sub-floor

1-1/2” (38 mm)

max. thickness

(including

Micore

)

Appliance base

1/2” combustible

shim at ends to

match

Micore

Lower panel

Removable panel

1-1/2” (38 mm)

Front of

appliance

Plywood

Appliance base

QUALIFIED

INSTALLER