53

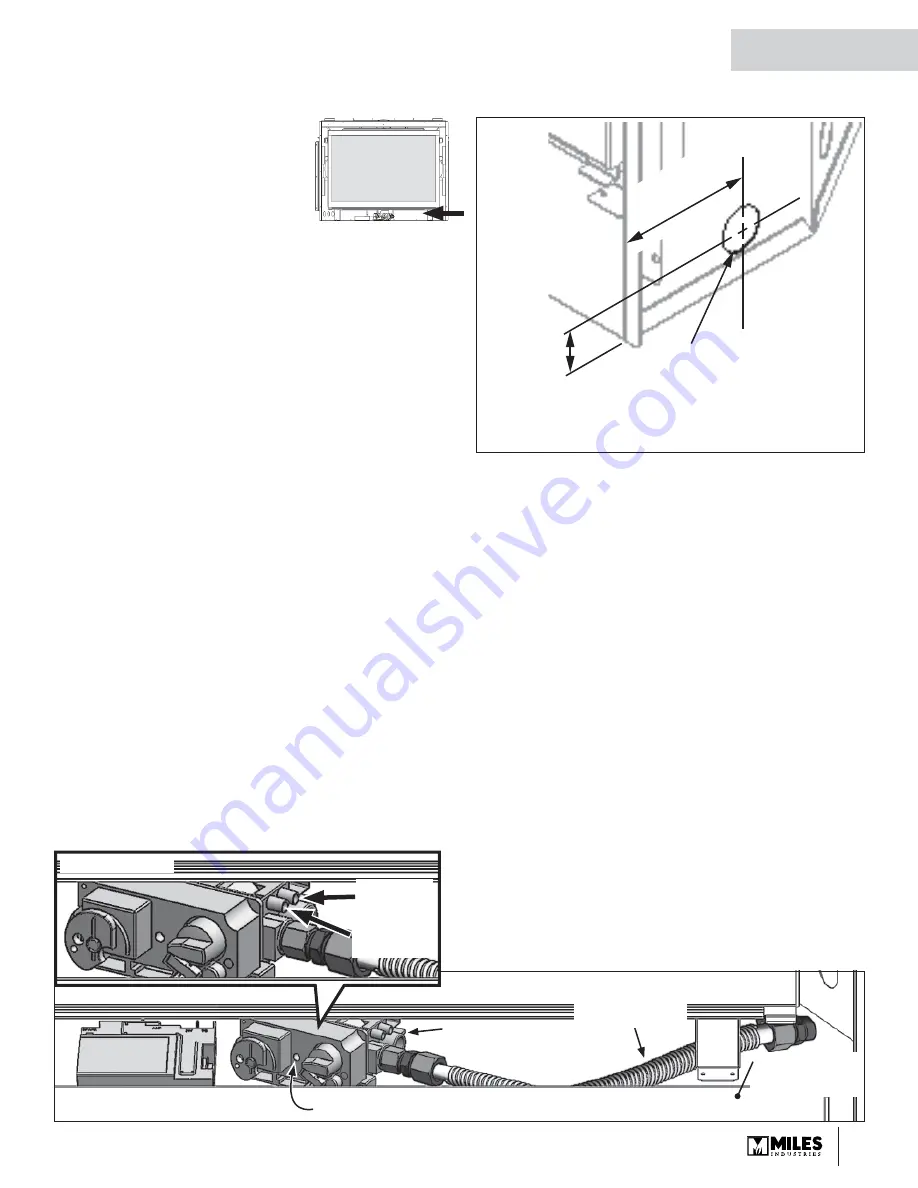

X

1-5/8”

(40 mm)

4-3/8”

(110 mm)

Gas line

access hole

1-1/2” (38 mm)

diam.

Connect Gas Supply

The gas supply inlet connection is a

3/8” NPT male connector located on

the right hand side of the fi rebox.

The unit is supplied with a stainless

steel fl ex line to allow the appliance

to be disconnected for service. An individual shut-

off valve (not supplied) is required on the supply line

ahead of the fl ex connector.

Use only new black iron or steel pipes or copper tubing

if acceptable—check local codes. Note that in USA,

copper tubing must be internally tinned for protection

against sulfur compounds.

Unions in gas lines should be of ground joint type.

The gas supply line must be sized and installed to

provide a supply of gas suffi cient to meet the maximum

demand of the appliance without undue loss of pressure.

Sealant used must be resistant to the action of all gas

constituents including LP gas. Sealant should be ap-

plied lightly to male threads to ensure excess sealant

does not enter gas lines.

Pressure test the supply line for leaks.

The appliance and its individual shut-off valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psig (3.5 kPa).

The appliance must be isolated from the gas supply

piping system by closing its individual manual shut-off

valve during any pressure testing of the gas supply pip-

ing system at test pressures equal to or less than 1/2

psig (3.5 kPa).

Failure to either disconnect or isolate the appliance

during pressure testing may result in regulator or valve

damages and void the warranty. Consult your dealer in

case of damages.

Gas line access—right side view

Valve assembly

Pressure testing

Manifold pressure adjustment

behind plastic cap

Control

Valve

Valve inlet

pressure

Manifold

test pres-

sure

Receiver

Flexible connec-

tor supplied with

unit

Valve cover on

front of the appli-

ance

Pressure Test Points

The minimum supply pressure is given in the section

Speci

fi

cations

of this manual—page 15.

All piping and connections must be tested for leaks af-

ter installation or servicing. All leaks must be corrected

immediately.

When testing for leaks:

• Make sure that the appliance is turned off .

• Open the manual shut-off valve.

• Test for leaks by applying a liquid detergent or soap so-

lution to all joints. Bubbles forming indicate a gas leak.

Never use an open fl ame to check for leaks.

Correct any leak detected immediately.

The pressure test tapping locations are shown in the fi g-

ure below. An internal regulator within the valve controls

the burner manifold pressure.

The correct pressure range is shown in the table in sec-

tion

Speci

fi

cations

of this manual on page 22. The pres-

sure check should be made with the burner alight and at

its highest setting. See

Lighting Instructions

section for

full operating details on page 15.

Installation

QUALIFIED

INSTALLER

Summary of Contents for 1100JN

Page 78: ......