17

Crack

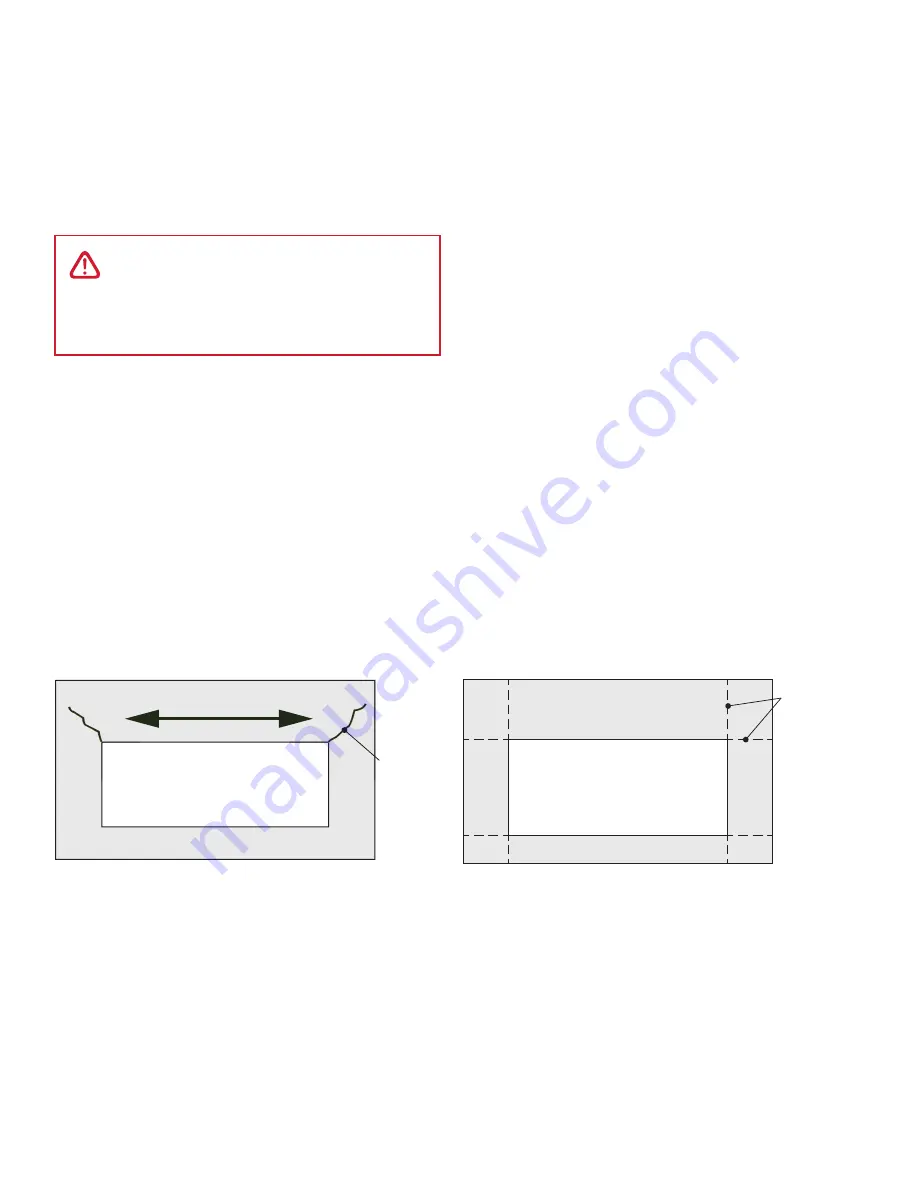

Provide joints

either here or

here

Avoiding Cracking Wall Finishes

We recommend installing the optional LDK HeatShift

Duct Kit to reduce the wall temperatures and

minimize the possibility of cracking wall

fi

nishes.

If a clean

fi

nish with no tile, etc. is desired, joints in the

cement board and the transition to gypsum board

will require special attention if future cracking is to be

controlled. Be aware that temperatures on the non-

combustible wall surface above the appliance can

exceed 200°F (93°C).

Below are some tips on how to best avoid any cracking:

• Allow materials to dry thoroughly before

fi

nishing the

wall. Cement board has the ability to absorb up to 30

percent of its weight in water and may shrink as much

as 1/8” over a 48” length when drying from a satu-

rated condition. Running the

fi

replace for an extended

period before

fi

nal

fi

nishing will help drive out mois-

ture.

Installation Planning

Wall Finish

• Always pre-drill screw holes through cement board

and use screws with self-milling head.

• Always use mesh tape over joints.

• Always stagger joints in wall board.

• Behind joints, double up studs or use studs “on the

fl

at” to add extra support to the joint. Adhesive on

the backside of wall board behind any joints can help

control di

ff

erential movement.

• Use multiple, thinner coats of joint compound and al-

low to dry thoroughly between coats.

• Ensure framing materials are dry.

• After

fi

nishing the wall, introduce heat gradually to

slowly dry any excess moisture rather than drying too

fast.

• Avoid notching cement board or tiles around corners

of window opening and instead provide a joint that

intersects the corner.

• Avoid using lage one-piece slab of material with a

cut-out in the middle as a surround for the

fi

replace.

Expansion above the opening will cause cracking at

inside corners. Provide a joint that intersects the inside

corner to avoid cracking.

WARNING

HeatShift System MUST be installed on

this appliance when using 1530CIK—Clean

Installation Kit.