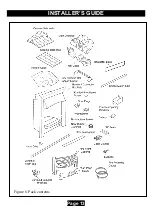

INSTALLER GUIDE

THIS APPLIANCE IS FOR USE WITH NATURAL GAS (G20)

WHEN CONVERTED USING CONVERSION KIT NO. 0591301 THIS

APPLIANCE IS FOR USE WITH PROPANE GAS (G31)

THIS APPLIANCE IS FOR USE IN THE UNITED KINGDOM (GB) AND THE

REPUBLIC OF IRELAND (IE) ONLY.

INSTALLER: Please leave this guide with the owner

Manufactured exclusively for British Gas & Scottish Gas by Valor Heating

For Service Phone 0845 960 5040

Because our policy is one of constant development and improvement, details may vary

slightly from those given in this publication.

© Valor Heating

C1

INSET LIVE FUEL EFFECT GAS FIRE

(GC No. 32-032-46)

INCORPORATING THE

CONTROL

(Manufacturer ref. 640)

3002526/03