INSTALLER’S GUIDE

Page 7

appliance is suitable for

installations under all

circumstances unless there is a

history of cracking problems.

Remember that faults such as

cracking may be caused by

poorly built and restrictive flues,

e.g. mortar extrusions, too many

bends, flue heights below three

metres, restrictive terminations

etc.

2.2.3

If the fireplace opening is

greater than the acceptable

dimensions given in this guide,

do not use the back of a fire

surround or marble to reduce the

opening. This may cause

cracking of the surround back or

marble.

2.4

Suitable flues and

minimum flue sizes are as

follows: -

It should be noted that, as with

many appliances, sharp bends or

horizontal runs in metal flues at

the top of the system can be a

cause of problems in these types

of installation.

•

225mm x 225mm

conventional brick flue.

•

175mm diameter lined brick or stone flue.

•

200mm diameter factory made insulated flue manufactured to BS4543.

•

175mm diameter flue pipe. See BS6461 Part 1 for suitable materials.

•

Single wall, twin wall or flexible flue liner with a minimum diameter of 125mm. The

materials to be used are stainless steel or aluminium as specified in BS715. The liner

must be sealed to the surrounding area above the fireplace opening and to the top of the

chimney. An approved terminal must be fitted.

•

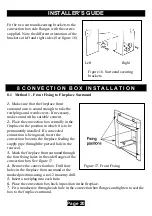

A properly constructed precast concrete or clay flue system conforming to BS1289 or

Figure 3. Precast or clay flue block system