28

28

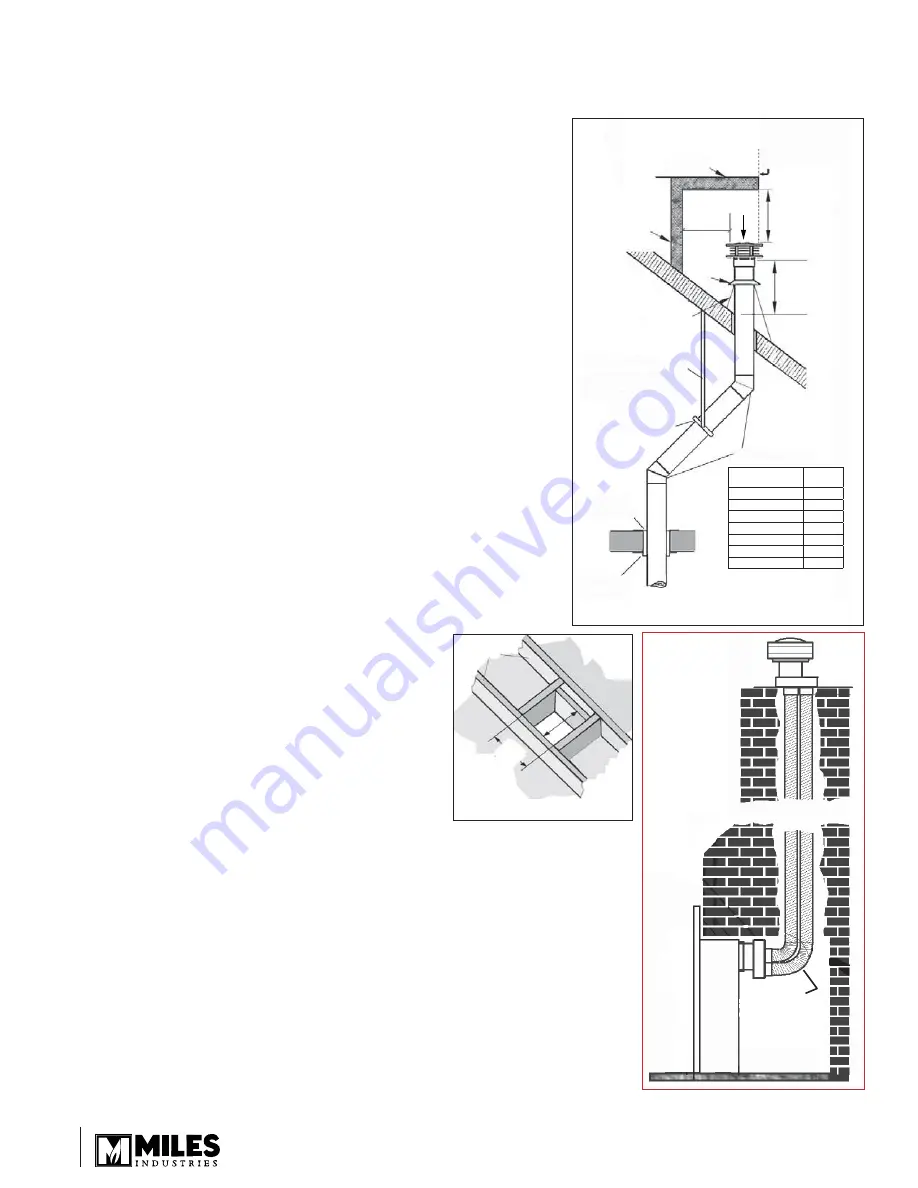

2 - 3”

Liners

‘H’

Horizontal

overhang

Vertical

wall

Termination

cap

Storm

collar

Roof

flashing

Plumber’s tape

fixed to wall strap

Wall strap

Ceiling

firestop

Ceiling

support

Offset elbows

Min.

18”

Overhang should

not extend beyond

vent if within 48” of

termination cap

Min. 24”

(unvented soffit)

Min. 36”

(vented soffit)

Roof Pitch

Minimum

‘H’ (feet)

Flat to 7/12

1’

Over 7/12 to 8/12

1.5’

Over 8/12 to 9/12

2’

Over 9/12 to 10/12

2.5’

Over 10/12 to 11/12

3.25’

Over 11/12 to 12/12

4’

Over 12/12 to 14/12

5’

Joists

10”

(254 mm)

10”

(254 mm)

Installations with Vertical Termination—Through the Roof

All Co-Axial Vent Installations

Check the roof pitch to determine which roof

fl

ashing will be needed.

See venting accessories list on pages 39–40 for allowable components.

The distance from the roof to the lowest terminal discharge opening

(“H” in

fi

gure 35) depends on the roof pitch and must be in accordance

with the manufacturer’s instructions supplied with the termination unit.

Note: The venting system for these appliances is considered to be a

Special Venting System. The rule in the Installation Code requiring

a minimum vent height of 2’ above any portion of a building within 10’

does not therefore apply.

The minimum clearances to combustible materials all round the vent

pipes must be in accordance with the dimensions shown in the Location

section of this manual.

Drop a plumb from the ceiling to the center of the appliance vent

opening. Mark the position on the ceiling. Drill a small hole at the

marked position.

Determine the position where the vent will pass through the roof. If

directly above the position where it penetrates the ceiling, drop a plumb

from the roof to the small hole in the ceiling and mark the roof at this

spot.

If rafters or other obstructions will prevent a vertical exit or if clear attic

space is desired, the roof outlet can be offset using 45° elbows. See

fi

gure 35.

Drill a small hole at the marked position.

A ceiling

fi

restop must be installed at the second

fl

oor and higher

fl

oors.

A ceiling support should be used below the

fl

at ceiling.

To install the

fi

restop and support, cut and frame a 10” (254 mm)

square hole centered on the small hole previously drilled. See

fi

gure 36.

Fit vent accessory elbows and pipe lengths as required

up through ceiling support boxes and

fi

restops.

If installation includes offset, support the offsetting pipes

every 3’ (1 m) with wall straps. See

fi

gure 35.

Cut a hole in the roof centered on the small hole.

The hole must allow for the minimum clearances to

combustible materials. See

Location

section in this

manual.

Fit pipe lengths through the roof. Fit roof

fl

ashing

securing it with roo

fi

ng nails.

Fit storm collar and termination cap.

•

•

•

•

•

•

•

•

•

•

Figure 35 Through the roof installation

Figure 36 Firestop hole

Co-Linear Vent Installations

The chimney and

fi

replace opening sizes are shown in

Dimensions

and

Location

sections of this manual.

Place the appliance (

fi

tted with the co-linear adapter) near the

fi

replace opening but

allow space for manipulating the chimney liners on to the appliance.

Drop the 3” dia.

fl

exible liners into the chimney from outside.

Fit the liners to the co-linear adapter paying attention to inlet and exhaust and move

the appliance to its proper position. Be aware of the minimum liver bend radius and

maximum liner horizontal run shown on page 17 of this manual.

Fit the termination kit and

fl

ashing to the exterior of the chimney.

Secure the appliance to the

fl

oor or wall if necessary.

•

•

•

•

•

•